|

|||

|

|

|||

|

Page Title:

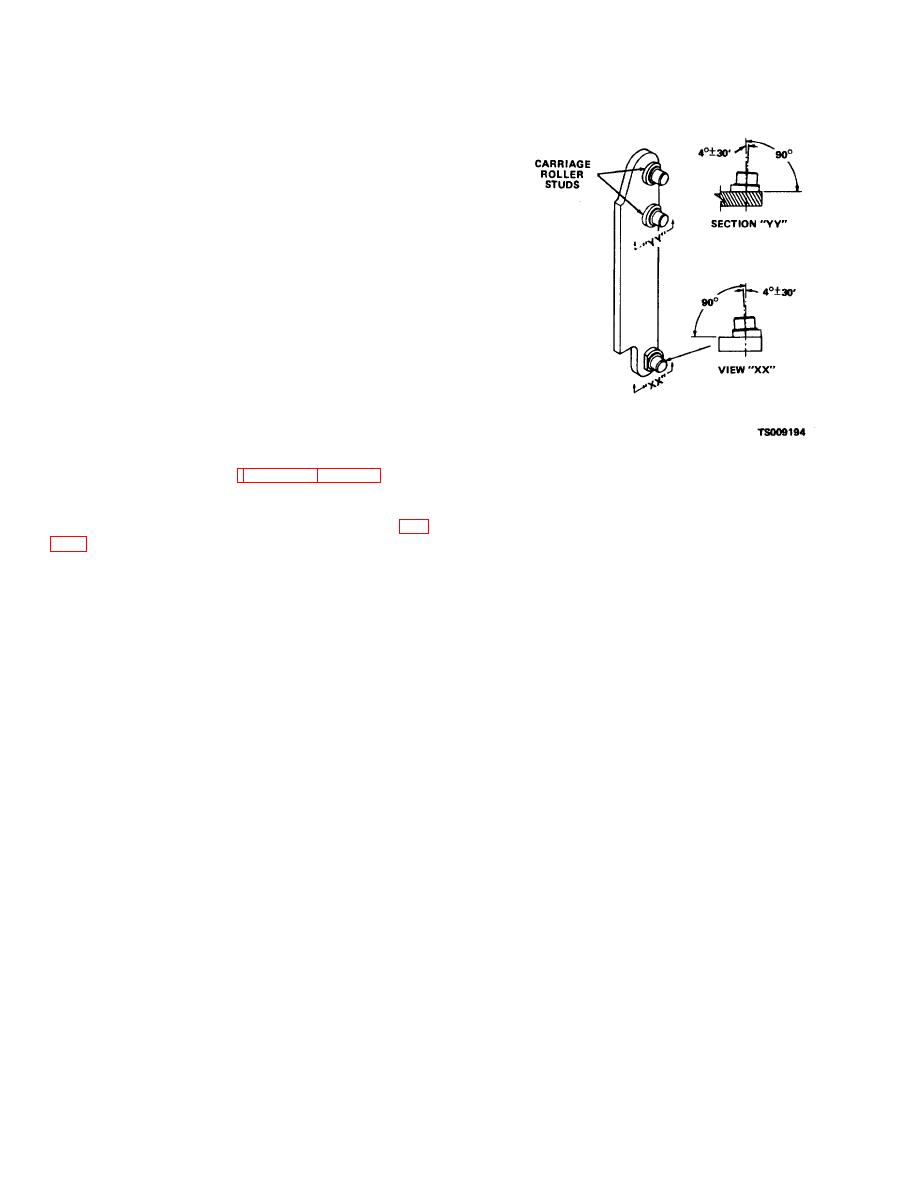

Figure 7-16. Carriage roller stud locations. |

|

||

| ||||||||||

|

|

TM 10-3930-631-34

(2) Inspect all parts for cracks, broken welds

and other damage.

(3) Replace wear strips and wear angle if wear

surface has worn to a thickness of 0.063 inch (1.60 mm).

(4) Inspect bearings for wear and damage.

Inspect for cracked inner or outer races. Replace worn

or damaged bearings.

(5) Inspect bearings studs for wear and

damage. If studs are worn or damaged, remove studs

and weld new studs on supports as follows:

Note

The following procedures apply to carriage and

mast bearing studs.

(a) Remove the filler metal from around the stud

using a small, round grinder. Do not make any passes

into the mast channel or carriage supports. Remove the

stud from the channel or support.

(b) Prepare the welding surface by removing all

foreign material such as rust, scale, grease, etc. Any

part that may be damaged by heat should be removed

before welding.

(c) Locate, tilt and aline the new stud on mast

Figure 7-16. Carriage roller stud locations.

channel or support. Refer to figure 7-16 and 7-21 for

dimensions and stud locations.

(d) Comply with the following welding

specifications using bearing stud welding procedure (fig.

7-25

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |