|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 10-3930-631-34

can be pushed down evenly and flush with upper surface

(5) Replace any defective, damaged or scored

of spool and sleeve.

parts. Replace all seals and packings from kit provided.

(9) Install centering pin (21, fig. 5-4) and push

e. Assembly

into place until both ends are flush or slightly below

(1) Lubricate all parts with engine oil (OE),

sleeve diameter.

(2) Place housing (30) in a vise with upper end

(10)Place housing on a solid surface with the

of housing facing up.

port face down. Install spool assembly with splined end

(3) Install check valve spring (20) in bore of

of spool entering fourteen hole end of housing first.

housing with small end up. Install ball (28) into bore so

Push parts into place with a slight rotating motion. Make

that it rests on top f small end of spring. Check ball

certain parts do not cock out of position while installing.

action by pressing ball against spring with a small pin.

(11)Install spool assembly into housing bore until

(4) Place check valve seat (27) on hex wrench

flush with lower end of housing. When spool assembly is

and install in housing. Machined counterbore of seat

flush, check for free rotation by turning spool assembly.

must seat on ball. Tighten seat to of 150 pound inches

Hold parts in position and place on wooden block in vise.

(1.72 m/k).

Clamp vise lightly on port face of housing.

(5) Install spool (23) into sleeve (24). Spring

(12)Install new packing (25) on check valve plug

slots of both parts must be at the same end. Rotate

(26) and install plug in bore in housing. Press plug in with

spool carefully while sliding parts together. Check spool

finger pressure, rocking it slightly to prevent cutting

for free rotation. Spool must rotate freely.

packing.

(6) With spring slots in line, stand parts on end

(13)Install bushing (19), large outside diameter

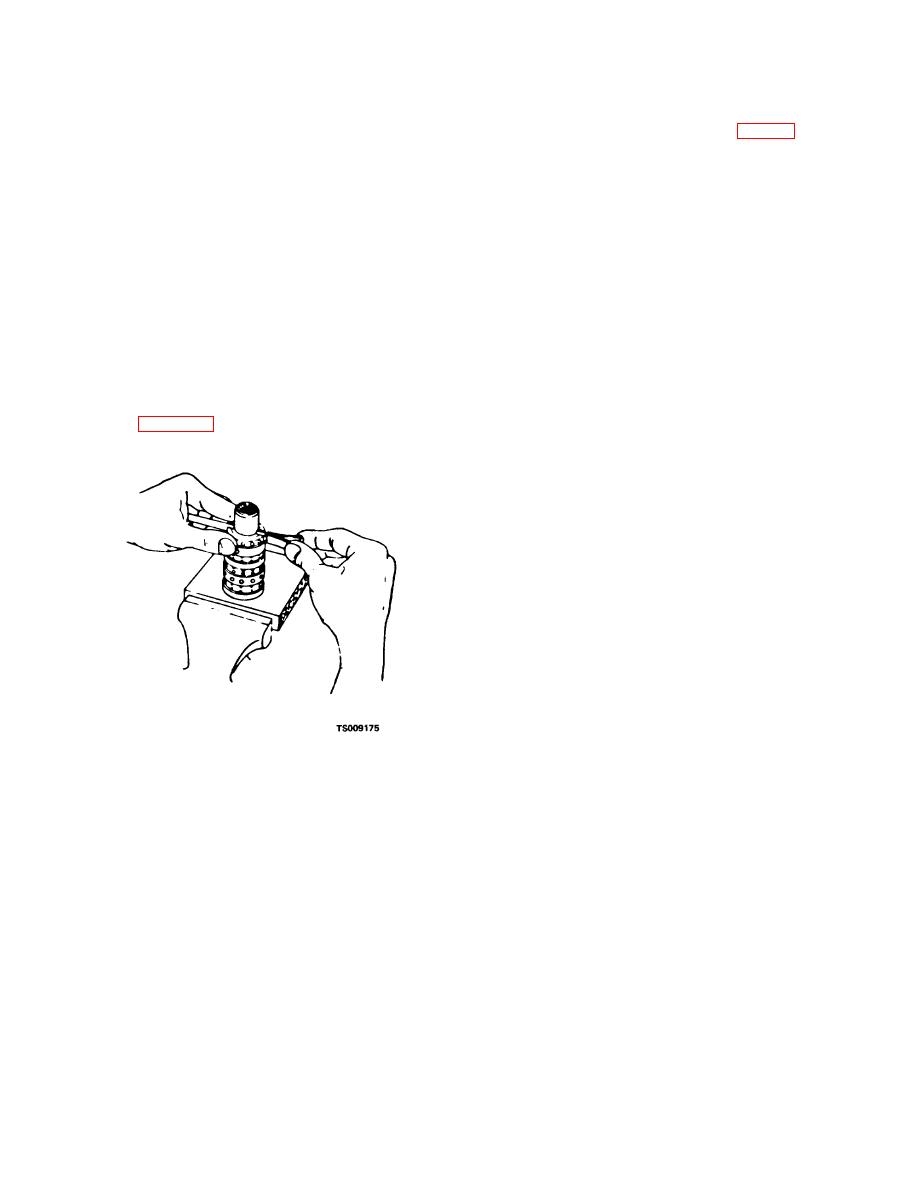

as shown in figure 5-7. Insert spring in- stallation tool

of chamfer up, partially into housing. Rotate bushing to

through slots in both parts.

seat bushing flatly and smoothly against spool assembly.

(14) Install new seal (18) on bushing. Install new

seal (15) in mounting plate (17). Push seals carefully

into seal grooves. Install seal (15) with the seal lip up.

(15)Place mounting plate (17) over spool shaft

and in place over cap locator bushing. Install carefully so

as not to displace seals.

(16)Mounting plate must fit flush against housing

assembly and locator bushing must not be cocked.

Secure mounting plate with screws (13). Tighten screws

to a torque of 250 pound inches (2.86 m/kg).

(17)Position housing in vise with lower end up.

Spool assembly must be flush with surface of housing.

Wipe surface of housing with hand to clean it. Install

plate (35) on housing.

(18)Install gear ring (part of gerotor set (34)) on

plate. Install splined end of drive gear (33) in splines of

star gear with slot in splines alined with valleys between

star gear teeth.

(19)Push splined end of drive gear through star

Figure 5-7. Installing centering spring set.

gear until approximately one-half of its length extends

beyond star gear. Install star gear in gear ring and

(7) Position three sets of centering springs on

position parts so that drive gear remains in position with

bench so that extended edge is down and arched center

star gear. Rotate gear ring slightly to engage cross slot

section are together. In this position install one end of

with centering pin in sleeve and splined end of drive gear

spring set in installation tool.

against plate.

(8) Compress extended end of centering

Note

springs and push into spool-sleeve assembly,

Proper alinement of drive gear with valleys of

withdrawing installation tool at the same time. Springs

star gear determines proper valve timing

must be centered in parts so that springs

(20)Place plate (35) on star gear. If plate

5-9

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |