|

|||

|

|

|||

|

Page Title:

Cleaning, Inspection and Repair. |

|

||

| ||||||||||

|

|

TM 10-3930-631-34

assemblies (9). Remove ring (11) and insulator (12)

from shaft (10) and flange (14).

(6) Clamp valve unit in a vise and remove

screws (31). Remove cap (32), gerotor set (34),

plate (35) and drive gear (33) as a unit.

(7) Remove unit from vise and insert splined

end of column assembly into lower unit as shown in

control spool and sleeve parts. Spool should rotate

freely.

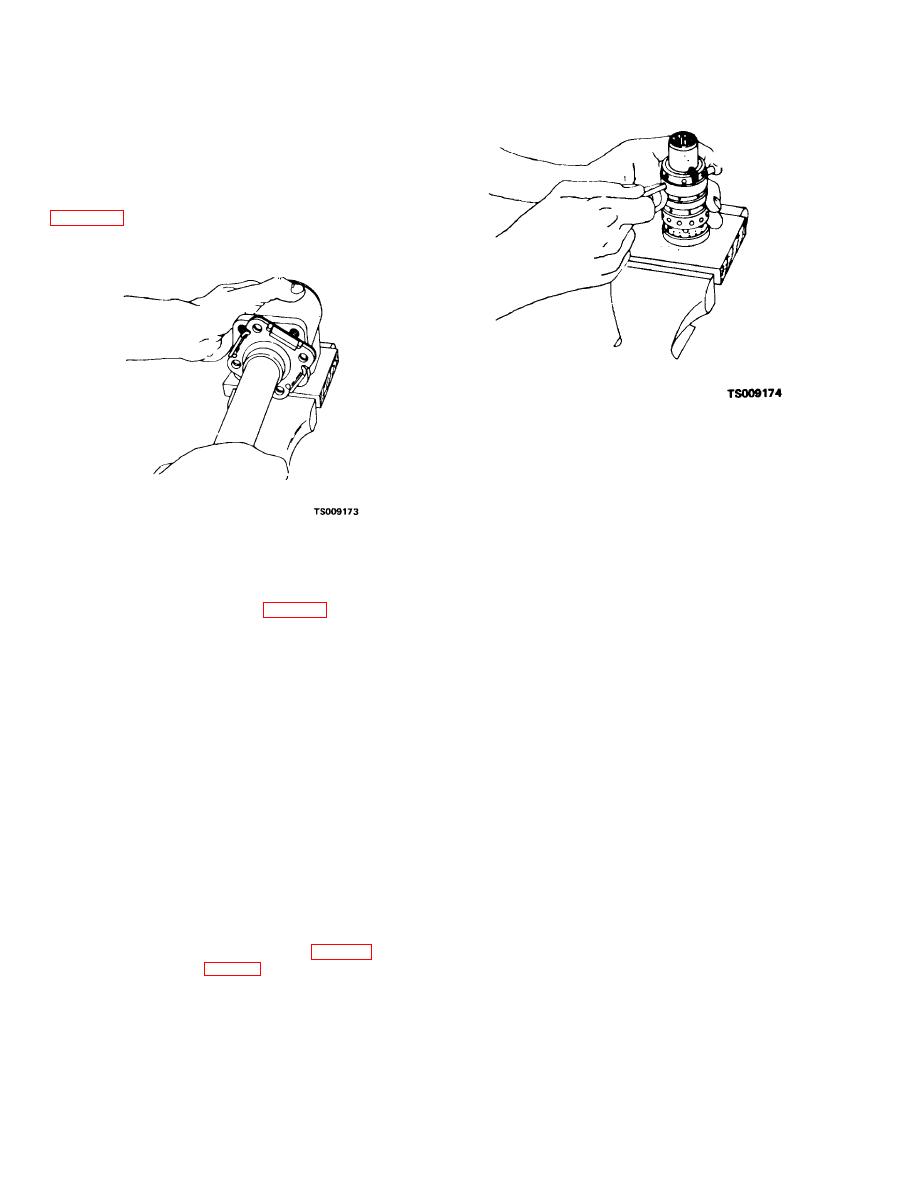

Figure 5-6. Loosening spool assembly.

(14)Push inside lower edge of spool so

spool moves toward splined end and remove spool

(23) carefully from sleeve.

(15)Push centering spring (22) out of spool.

(16)Remove gear (33), gerotor set (34) and

Figure 5-5. Checking spool rotation.

plate (35) from end cap (32).

c. Cleaning, Inspection and Repair.

(8) Place a wooden block in vise to support

(1) Clean all metal parts in cleaning com-

spool parts. Clamp unit across port face with control

pound, solvent (Fed. Spec. P-D-680). Place parts

end up. Remove screws (16, fig. 5-4). Hold the

on clean lint free cloth or paper and allow to air dry.

spool assembly down against the wooden block and

(2) Inspect surfaces of all moving parts for

remove mounting plate (17). Remove seals (15 and

scoring and other damage.

18) and discard seals. Remove bushing (19) and

(3) Slightly scored parts can be cleaned by

packing (20). Discard packing.

hand rubbing with fine abrasive paper.

(9) Place housing securely on a solid

(4) Prepare surfaces of gerotor set and

surface with the port face down. Remove pin (21),

plates as follows:

spring (22), spool (23) and sleeve (24) as an

(a) Place a sheet of fine (600 grit) abrasive

assembly. Use care when removing assembly.

paper, face up, on a piece of plate glass or similar

Parts are closely fitted and must be rotated slightly

smooth, flat surface.

as they are withdrawn.

(b) Clean ends of star gear (part of gerotor

(10)Use a small bent tool or wire and

set) by stroking it across the abrasive. This will

remove check valve plug (26) from housing. Do not

remove any sharp grit which could scratch other

pry against edge of hole in housing bore. Remove

components.

packing (25) and discard.

(c) Stroke each side of ring gear (part of

(11)Use a 3/16 inch (4.76 mm) hex wrench

gerotor set), both sides of gerotor plate and

and remove check valve seat (27) from housing.

mounting plate and the inner side of end cap.

(12)Turn the housing over and tap lightly to

(d) Hold parts as flat as possible against the

remove ball (28) and spring (29) from bore in

abrasive. Small bright areas on the faces indicate

housing.

burs which must be removed. After 6 to 10 strokes

(13)Hold the spool assembly (fig. 5-6) and

across abrasive check to see if part is polished. All

push the cross pin (21, fig. 5-4) to loosen it from the

parts should have smooth polished surfaces. After

spool and sleeve. Remove pin.

polishing each part, clean in solvent and blow dry

with air. Place parts in absolutely clean area to await

assembly.

5-8

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |