|

|||

|

|

|||

|

Page Title:

Cleaning, Inspection and Repair. |

|

||

| ||||||||||

|

|

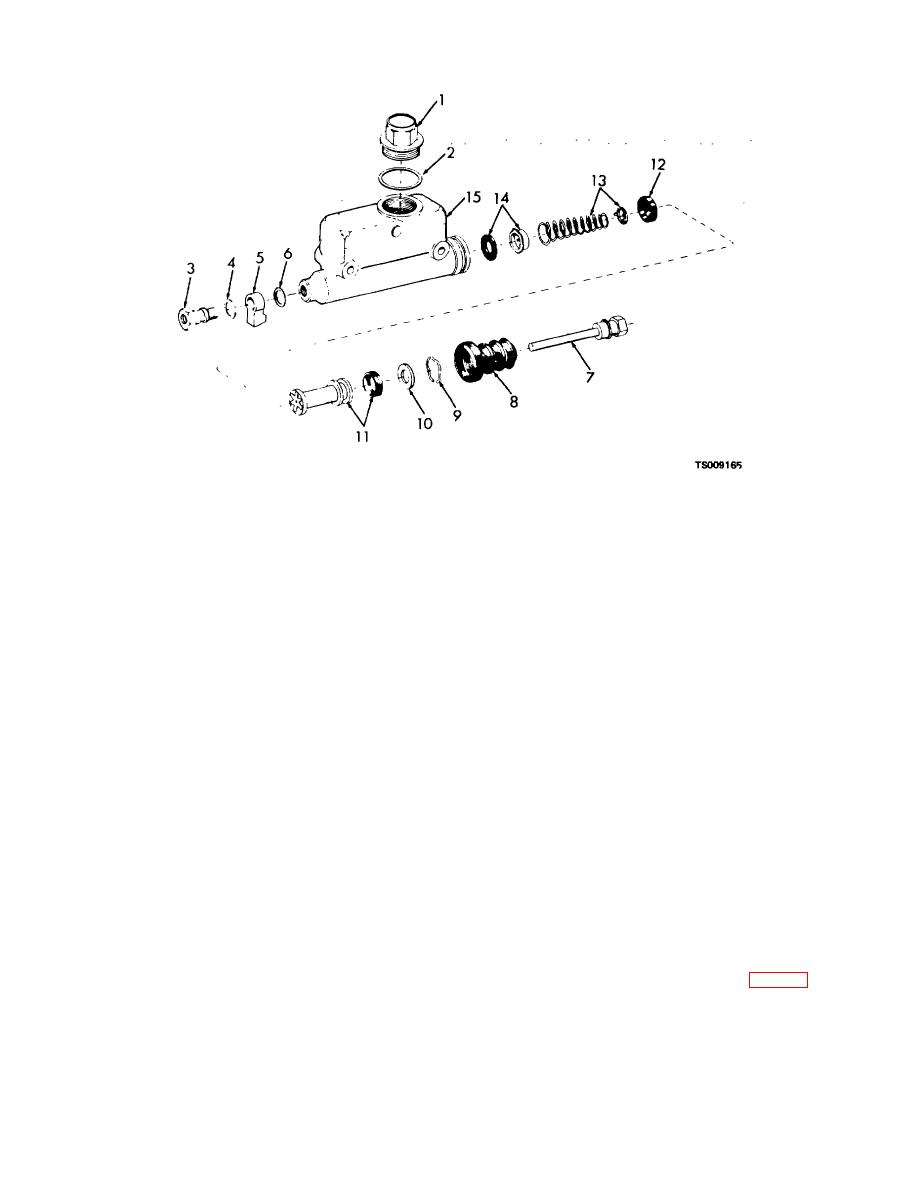

TM 10-3930-631-34

1.

Filler cap

6. Gasket

11.

Piston assembly

2.

Gasket

7. Piston rod

12.

Cup

3.

Fitting

8. Boot

13.

Spring assembly

4.

Gasket

9. Lock

14.

Valve assembly

5.

Fitting

10. Piston stop plate

15.

Body

Figure 4-5. Master cylinder, exploded view.

(3) Remove push rod (7) and boot (8). Carefully

spect bore after each pass. Remove only enough

pry out lock (9).

material to recondition cylinder bore.

(c) If master cylinder has been honed to an

CAUTION

inside diameter greater than 1.007 inch (25.27 mm),

When lock is removed, spring tension is

replace body.

released and parts may fly out if not held in

(d) After honing, wash body in warm water and

place.

a soap solution.

(4) Remove stop (10), piston assembly (11),

(e) Check intake and bypass ports to be certain

cup (12) and spring and valve assemblies (13 and 14)

they are open and free of burs.

from cylinder body (15).

(f) Rinse body in clean warm water and blow

e. Cleaning, Inspection and Repair.

dry with compressed air. After drying immediately

(1) Wash parts thoroughly in denatured alcohol

immerse body in clean hydraulic brake fluid.

or clean brake fluid. Do not use mineral base solvents

(3) Inspect all parts for wear, corrosion and

which will deteriorate rubber parts.

(2)

damage. Replace all unserviceable parts. Install all new

Inspect bore of cylinder body. Check intake and

parts contained in repair kit for cylinder.

bypass ports, clean if necessary. Remove pressure

d. Assembly.

marks and discoloration from bore with fine crocus cloth.

(1) Lubricate all parts with clean hydraulic fluid.

Deep blemishes must be removed by honing as follows:

(2) Install valve assembly (14, fig. 4-5) in bore

(a) Secure body securely in a bench vise.

in body (15).

Install spring assembly (13) in

(b) Hone body as necessary, removing material

in single passes. Remove hone and in-

4-8

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |