|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 10-3930-631-34

b. Installation.

(1) Using a hoist, place carriage frame and side

shifter in position below inner mast. Aline bearings with

channels in inner mast.

(2) Using the hoist, raise and lower the carriage

in the inner mast several times to check for free

movement throughout entire range of travel. If bearings

bind, refer to paragraph 7-10 and shim bearings for

proper clearance.

(3) When carriage frame moves freely secure

chains to frame. Before releasing the hoist check t( see

that chains are secure at the cylinder cluster and running

evenly, with no twists, through the crosshead bearings.

Adjust chain length for even lift, if necessary. Refer to

TM10- 3930-631-12.

(4) Install screws and spacer on rear of

carriage supports.

(5) Remove blocks and lower inner mast to

floor, using a suitable hoist.

(6) Remove plugs and caps and connect

hydraulic hoses to side shift cylinder and swivel block on

carriage.

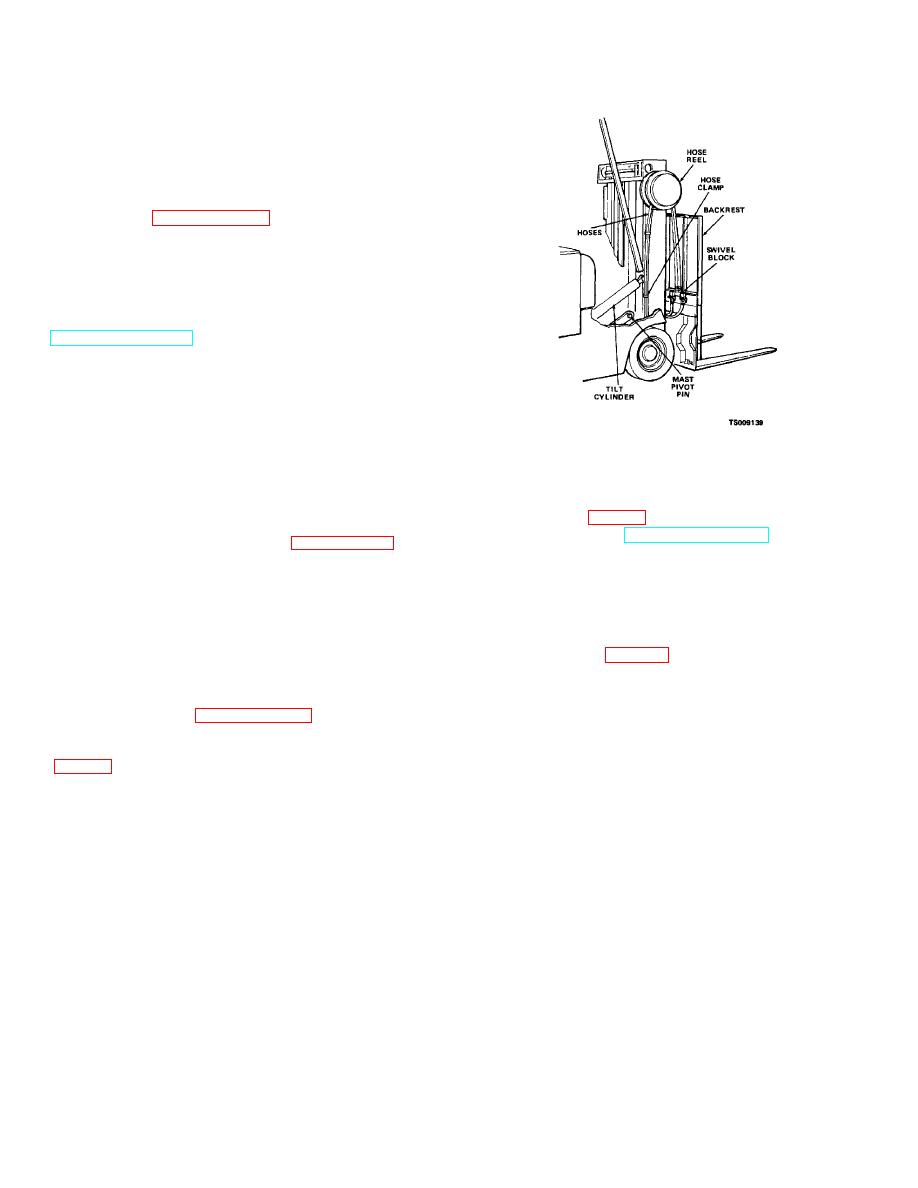

Figure 2-6. Side shift hoses and hose reel.

(7) Connect battery receptacle and operate

mast assembly through entire range of travel.

(3) Remove nuts, screws and lock washers and

(8) Check carriage movement for sideplay and

remove clamps (fig. 2-6) and hoses from outer mast.

binding. Check operation of side shift.

(4) Refer to TM10-3930-631-12 and disconnect

(9) If bearings bind, refer to paragraph 7-15e.

tilt cylinders from mast.

(7) to shim bearings and provide proper clearance.

(5) Disconnect hydraulic hose from flow

(10)Lower the carriage to lowest point of travel

regulator at rear of mast. Plug hose and hydraulic fitting

and check the distance from the lowest horizontal fork

to prevent entrance of foreign material.

3

1

support to the floor. Adjust to bring support to 2 /4 - 3 /4

(6) Connect a hoist to the mast assembly and

inches (69. 8 - 82. 5 mm) from floor. Refer to TM10-

raise the mast assembly enough to remove weight from

3930-631-12 for adjustment procedures.

mast pivot pin (fig. 2-6). Remove screws and lock

(11)Install carriage forks and lock in position.

washers and remove pivot pins.

2-15. Mast Assembly

a. Removal.

(1) Refer to paragraph 2-14 and remove side

shift carriage from mast assembly.

(2) Disconnect hydraulic hoses from hose reel

cap ends of hoses and fittings in junction block and hose

reel to prevent entrance of foreign matter.

2-12

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |