|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 10-3930-630-34

bolts to a torque of 85 to 95 foot pounds (115.2 to 128.8

N ).

m

(5) Try to turn crankshaft by hand. If a definite

drag is felt, the bearing and crankshaft are in tolerance.

(6) Remove bearing cap and remove feeler

stock. Repeat operation for each main bearing, one at a

time.

11-37. Crankshaft and Main Bearing Reassembly

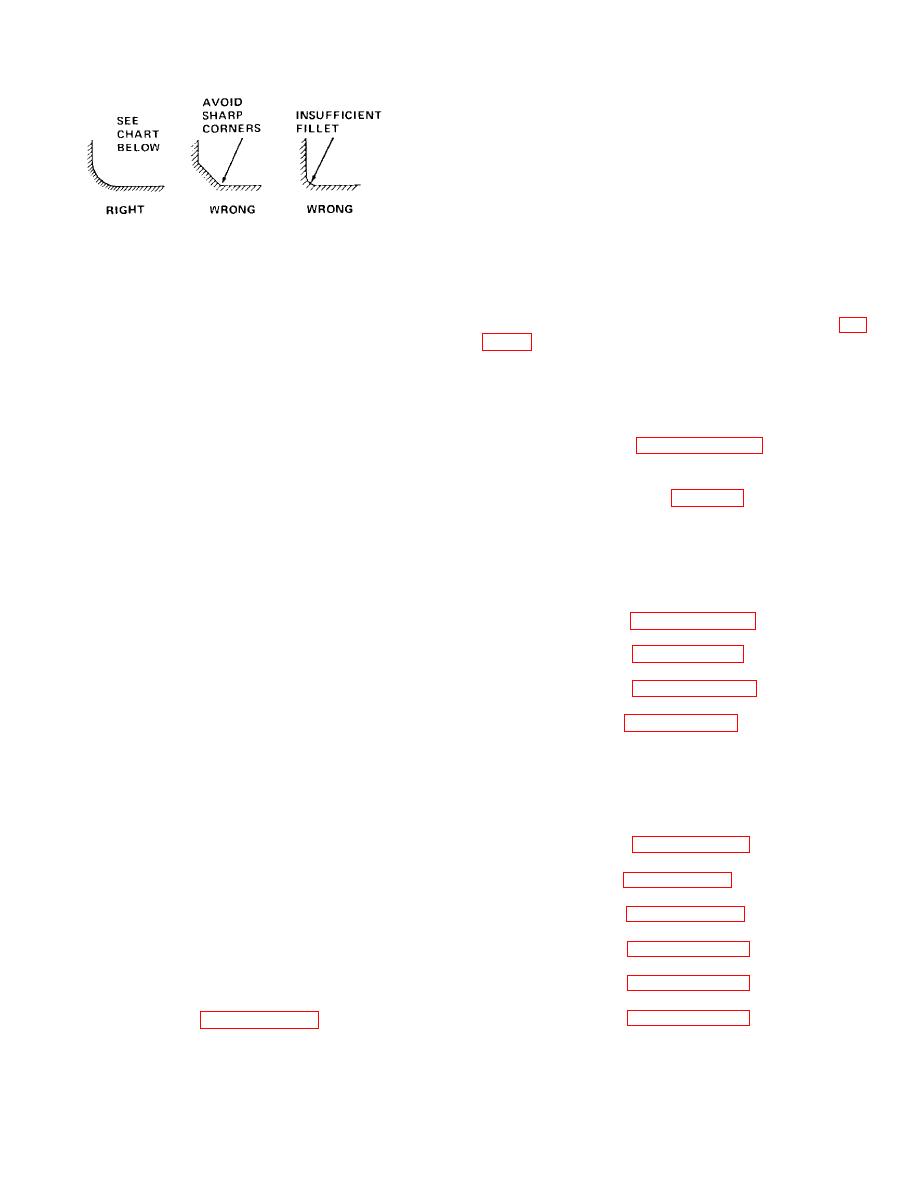

FILLET RADII.

and Installation

0.078 TO 0.108 INCH ON ALL CRANKPINS AND

a. Reassembly.

MAIN BEARINGS EXCEPT REAR MAIN BEARING.

(1) If not already installed, install upper main

0.110 TO 0.140 ON REAR MAIN BEARING.

and connecting rod bearing shells.

(2) Carefully lift and install crankshaft (16, fig.

TA067480

Install lower main and

Figure 11-40. Crankshaft fillet radii.

connecting rod bearing shells on journals.

(3) Install main bearing caps and tighten bolts to

(4)

Check bearing thickness with a micrometer

85 to 95 foot pounds (115.2 to 128.8 N ).

m

(a) Main bearing thickness must be

(4) Install connecting rod bearing caps and

0.0925 to 0.0928 inch (2.34 to 2.35 1mm).

tighten nuts to 40 to 45 foot-pounds (54.2 to 61.0 N ).

m

(b) Connecting rod bearing thickness

(5) Refer to paragraph 11-12 and install oil

must be 0.0616 to 0.0613 inch (1.56 to 1.55 mm).

pump and secure to main bearing cap with nut and

(5) Replace main bearings if thickness is less

lockwasher.

than 0.0920 inch (2.33 mm). Replace connecting rod

(6) Install key (7, fig. 11-39) and gear (6) on

bearings if thickness is less than 0.608 inch (15.4 mm).

crankshaft. Use a driving sleeve to tap gear snugly in

k. Check bearings as follows:

place. Install pump coupling (4) and retaining rings (2).

(1) Install upper shells of main bearings and

Secure coupling and gear with screw (1). Tighten screw

connecting rod bearings in block and connecting rod.

to a torque of 140 to 150 foot pounds (189.8 to 203.3

(2) Install crankshaft in block and connecting

N ).

m

rods.

b. Installation.

(3) Place a piece of feeler stock, 0.0010 inch

(1) Refer to paragraph 11-23 and install fan

(0.0025 mm) thick across main bearing shells.

drive and gear cover.

(4) Install main bearing cap and evenly tighten

(2) Refer to paragraph 11-9 and install the oil

pan.

(3) Refer to paragraph 11-31 and install the

flywheel housing an(d flywheel.

(4) Refer to paragraph 2-24 and install engine

in truck.

Section VII. CLYINDER BLOCK

(2) Refer to TAM 10-3930-630-12 and remove

11-38. Description

the cylinder head and manifolds.

The cylinder block and( crankcase are cast as a single

(3) Refer to paragraph 11-3 and remove the

unit. Bearing crosswalls and water baffles are filleted.

valve mechanism.

Honed cylinder bores are exposed to coolant for their

(4) Refer to paragraph 11-7 and remove the oil

entire length. Intake and exhaust ports are arranged

pan.

along the upper left side of the cylinder block. Directly

(5) Refer to paragraph 11-10 an(d remove the

below the ports is a valve and tappet chamber enclose(l

oil pump.

by a cover. The camshaft extends the length of the left

(6) Refer to paragraph 11-17 and remove the

side of the crankcase and rotates in three bearings.

pistons and connecting rods.

(7) Refer to paragraph 11-21 and remove the

11-39. Cylinder Block, Removal and Disassembly

gear cam and fan drive.

a. Removal

(8) Refer to paragraph 11-24 and remove the

(1) Refer to paragraph 2-22 and remove the

camshaft.

engine from the truck.

11-27

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |