|

|||

|

|

|||

|

Page Title:

Section V. FLYWHEEL AND FLYWHEEL HOUSING |

|

||

| ||||||||||

|

|

TM 10-3930-630-34

Section V. FLYWHEEL AND FLYWHEEL HOUSING

11-27. Description

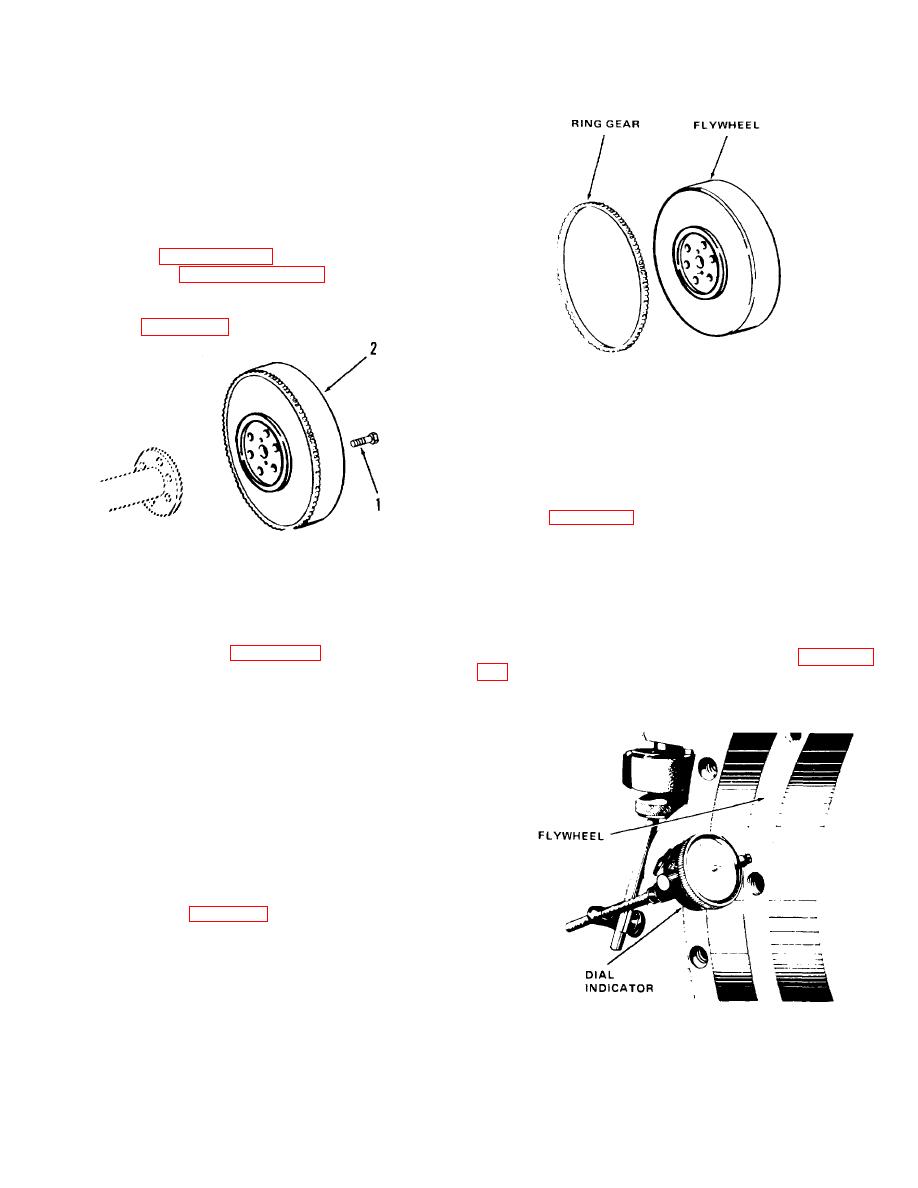

a. The flywheel is mounted on the rear end of the

crankshaft. The ring gear is mounted around the

flywheel and meshes with the starter gear to start the

engine.

b. Timing decals are mounted on the flywheel to

aid in timing the engine.

11-28. Flywheel, Removal and Disassembly

transmission and torque converter.

c. Remove the flywheel in numerical sequence as

illustrated on figure 11-31.

TA067472

Figure 11-32. Flywheel ring gear, removal and

installation.

11-30. Flywheel, Reassembly and Installation

a. Install two guide studs (3/8 - 24 x 4 inches long)

in crankshaft flange and install flywheel on studs. Install

screws (1, fig. 11-31) and tighten screws to a torque of

35 to 40 foot-pounds (47.4 to 54.2 N ). Remove guide

m

TA067471

studs an(d install remaining screws.

1. Screw

2. Flywheel

b. Check flywheel as follows:

(1) Mount a dial indicator as shown in figure

Figure 11-31. Flywheel, removal and installation.

11-33. Set indicator to contact vertical surface of

flywheel. Maximum indicator reading must not exceed

11-29. Flywheel, Cleaning, Inspection and Repair

0.008 inch (0.203 min).

(2) Mount dial indicator- as shown in figure 11-

and damage. If ring gear is damaged, remove ring gear

as follows:

reading must not exceed 0.008 inch (0.203 mm).

(1) Grind a notch in ring gear at root of one of

the teeth.

(2) Heat gear to 475F (246C) to expand

gear. Pry gear from flywheel.

b. Clean all metal 1)arts in cleaning compound,

solvent (Fed. Spec. P-D-680) and dry thoroughly.

c. Inspect mounting surface of flywheel for burs

and nicks. Remove burs and nicks with fine emery

cloth.

d. Inspect mounting holes and crankshaft flange

for elongation and damage.

e. Replace unserviceable parts.

gear to 475F (246C). Start ring gear on flywheel with

chamfered ends of teeth set to engage starter gear.

Drive ring gear down tight against the shoulder on

flywheel. Let ring gear cool slowly.

TA067473

Figure 11-33. Checking flywheel run-out.

11-22

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |