|

|||

|

|

|||

|

Page Title:

Section II. OIL PAN, OIL PUMP AND PRESSURE RELIEF VALVE |

|

||

| ||||||||||

|

|

TM 10-3930-630-34

block. Install tappets in same bore from which they

were removed.

g. Install valve and valve spring in position in

correct cylinder. Install rotor (5) in exhaust valve bore.

Install spring retainer (4) in intake valve bore.

h. Use a valve removal tool and compress spring.

Insert locks to secure valves in position.

i. Refer to TM 10-3930-630-12 to adjust valve

clearances and install cylinder head and valve cover.

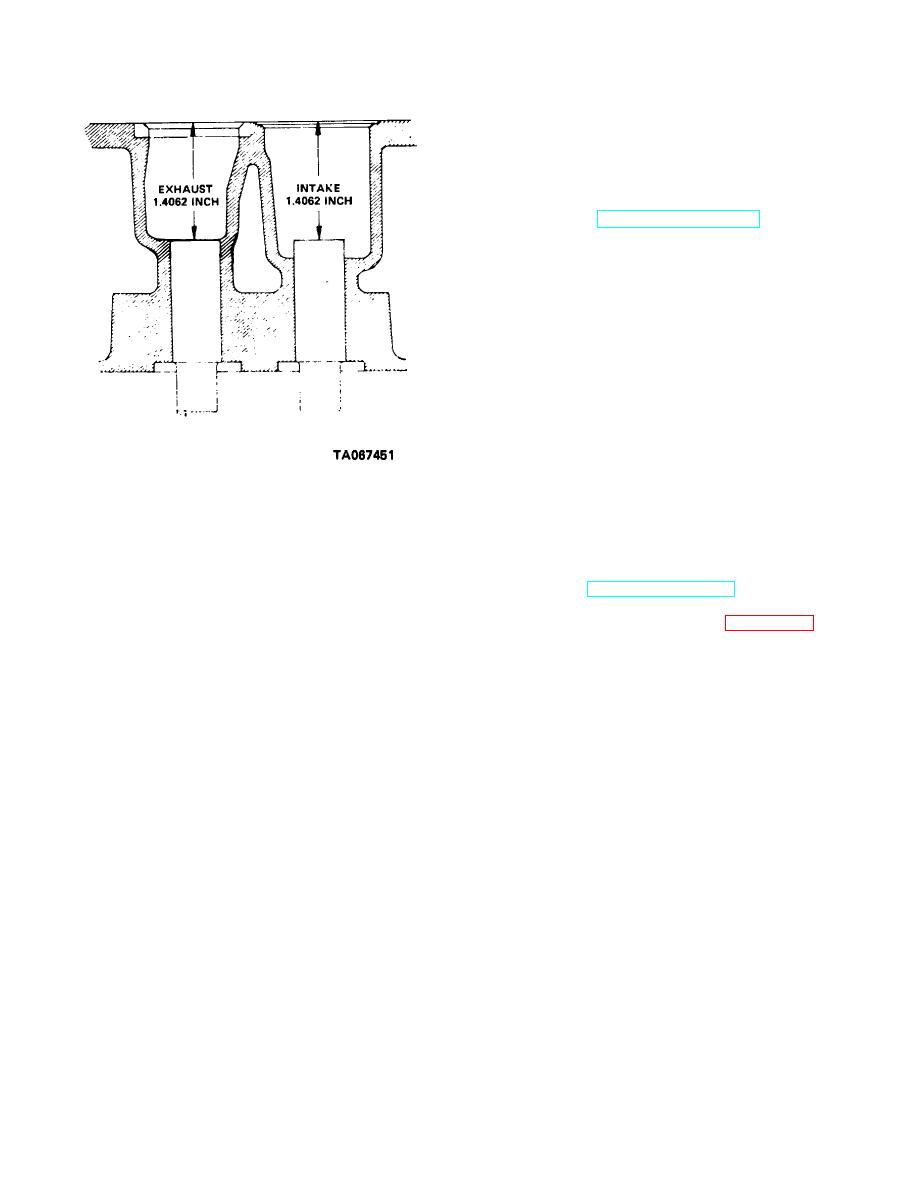

Figure 11-11. Valve guide installation.

Section II. OIL PAN, OIL PUMP AND PRESSURE RELIEF VALVE

11-7. Oil Pan, Removal and Disassembly

11-6. Description

a. Refer to TM 10-3930-630-12 and drain oil pan.

a. The oil pump is a positive gear type pump. A

b. Remove and disassemble the oil pan in

gear on the upper end of the pump body is driven by a

numerical sequence as illustrated in figure 11-12.

gear on the camshaft. The pump shaft is carried in two

bronze bearings mounted in the pump housing.

b. Pressure is regulated by a pressure regulating

valve mounted in the engine block.

11-7

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |