|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 10-3930-630-34

(3) Press bearing cones (4) and cups (5) on

threaded holes for damage. Repair damaged threads if

shaft (8).

possible.

(4) Secure bearings with washers (2 and 3)

f. Inspect cover for cracks and damage. Discard

and nut (1). Lock nut by bending tabs of washer (2).

cover gasket.

(5) Install new seal (11) in housing (21).

g. Check locating pin for secure mounting and

Install new gasket (19) and install cover (18). Secure

damage.

cover with screws (15 and 16) and lock washers (17).

h. Replace all unserviceable parts.

b. Installation.

(1) Refer to paragraph 94 and install the service

10-12. Drive Axle and Axle Shaft, Reassembly and

brakes.

Installation

(2) Refer to TM 10-3930-630-12 and install the axle

a. Reassembly.

shaft, spindle, and brake dust shield.

(1) Lubricate bearing cones (4, fig. 10-4) and

(3) Refer to paragraph 7-4 and install the drive

cup (5) with grease per LO 10-3930-630-12.

wheel on the truck.

(2) Install cap (7) and new seal (6) on shaft

(4) Refer to paragraph 2-30 and install drive axle on

(8).

the truck.

Section IV. DIFFERENTIAL

(8) Remove screws (1, fig.

10-6), lock

10-13. Description

washers (2) and bearing locks (3). Remove adjusting

The differential mounted on the rear of the drive axle, is

nuts (4) from bearing caps and housing. Remove lock

connected to the drive shaft. Rotation of the drive shaft

wire (5) and screws (6) securing bearing caps (7) to

rotates the differential. The axle shafts are splined to

housing. Remove bearing caps (7).

the differential. As they rotate the ends of the axle

shafts rotate in the bull gears. The bull gears and

wheels are mounted at the outer ends of the axle and

rotate to drive the truck.

10-14. Differential, Removal and Disassembly

a. Removal.

(1) Refer to paragraph 7-2 and remove the

drive wheels.

Refer to TM 10-3930-630-12 and

disconnect drive shaft from differential.

(2) Refer to LO 10-3930-630-12 and drain the

differential housing.

(3) Refer to TM 10-3930-630-12 and remove

the parking brake cable at the brake actuating lever, and

disconnect and plug the hydraulic brake lines.

(4) Using a suitable support for the

differential remove the screws which mount the carrier

and differential to the axle housing.

(5) Carefully remove carrier and differential

assembly from the axle housing and place on a suitable

work bench.

NOTE

It may be necessary to lightly tap the

carrier housing in order to free it

from seal.

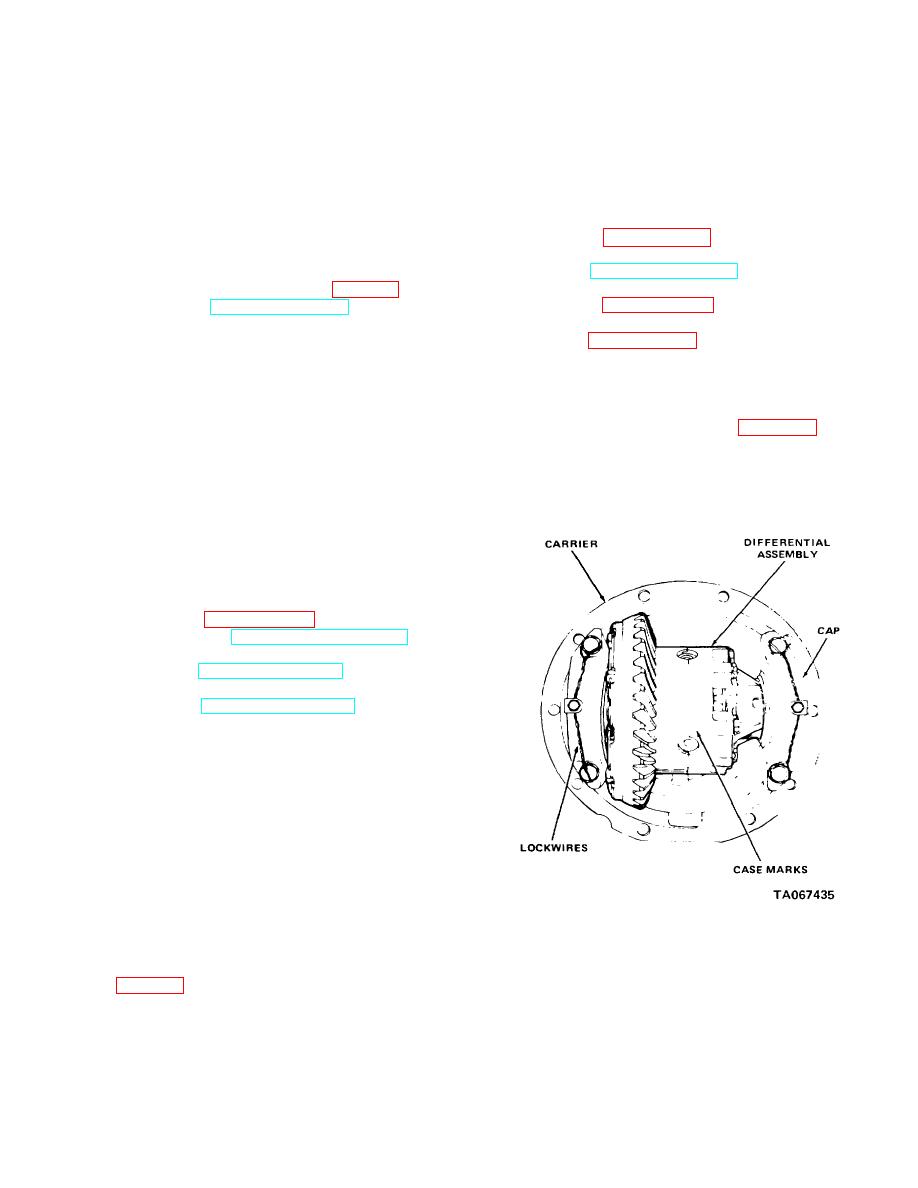

Figure 10-5. Differential, removal and installation.

(6) Remove and discard gasket between

carrier housing and axle housing

10-15. Differential, Cleaning, Inspection and Repair

(7) Match mark bearing caps and differential

a. Clean all parts with cleaning solvent, (Fed.

housing (fig. 10-5) to aid in proper alignment during

Spec.P-D-680).

reassembly

b. Inspect bearings for damage and excessive

wear. Replace if damage is noted.

10-6

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |