|

|||

|

|

|||

|

Page Title:

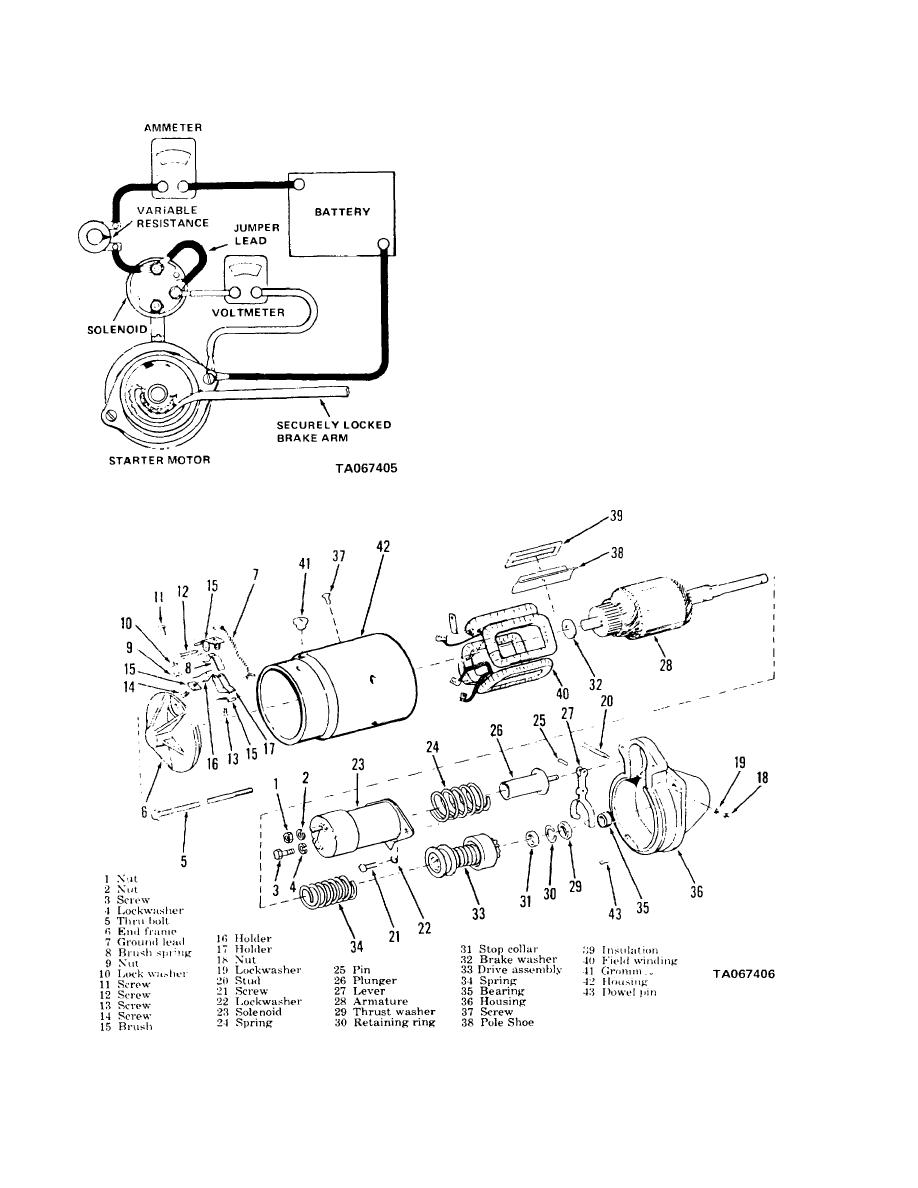

Figure 4-9. Starter, disassembly and reassembly. |

|

||

| ||||||||||

|

|

TM 10-3930-630-34

(2) Securely lock the pinion, using the

brake arm, to prevent the armature from turning.

(3) Energize the starter with 4 to 5 volts.

Adjust voltage with variable resistance.

(4) Current reading must be from 270 to

310 amps. If current is not within limits specified, repair

starter.

d. Disassembly. Disassemble the starter

assembly in numerical sequence as illustrated in figure

Figure 4-8. Starter resistance test.

Figure 4-9. Starter, disassembly and reassembly.

4-6

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |