|

|||

|

|

|||

|

Page Title:

Hydraulic Carriage, Reassembly and Installation |

|

||

| ||||||||||

|

|

TM 10-3930-630-34

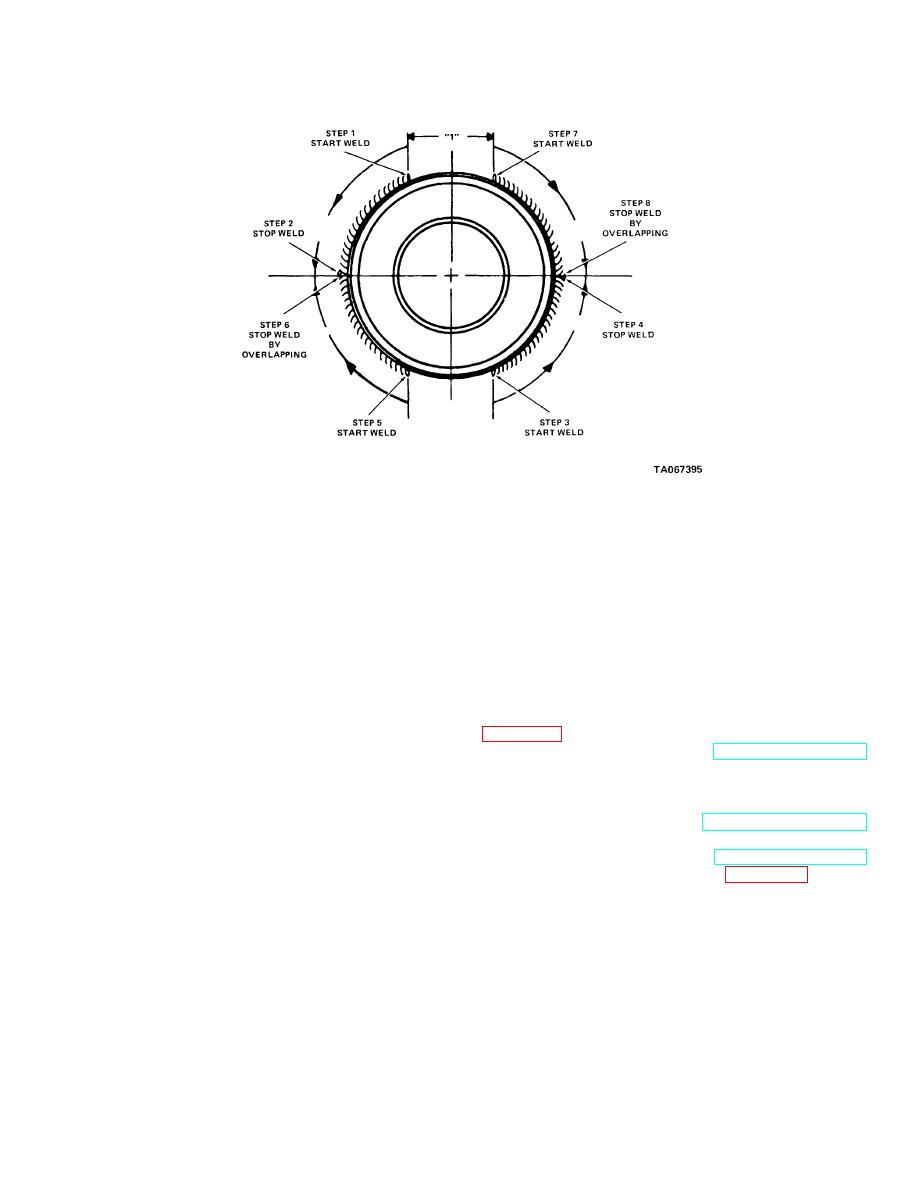

Figure 3-13. Bearing stud welding procedure.

(5) When welding is completed remove all

Process ..................

Shielded metal arc

slag, weld spatter and excess weld material.

Equipment..............

Manual

(6) Remove the defective material with a small

Settings:

round grinder in 0.010-0.020 inch (0.25 to 0.50 mm)

Current...................

A.C.

passes. Inspect for defects after each pass.

Amps .....................

275/375

Volts.......................

31/33

Base metals ...........

(1) AC 1035-P-1

3-30.

Hydraulic

Carriage,

Reassembly

and

..............................

(2) AC 86L20H (roller stud)

Installation

Plate thickness range

3/8 to 1 inch (9.5 to 25.4 mm)

a. Reassembly. Reassemble the carriage in

Electrode:

the reverse of numerical sequence as illustrated in

Type ................

Stick

Class ...............

E 7018 (hydrogen free)

b. Installation. Refer to TM 10-3930-630-12

Size .................

3/8 inch (9.5 mm)

and install the hydraulic carriage and backrest.

Flux .................

Electrode covering

Weld type and size.

1/4 inch (6.3 mm) fillet

3-31.

Mast Assembly, Removal and Disassembly

Number of passes

1

a. Removal. Refer to TM 10-3930-630-12

Position............

Horizontal

and remove the mast.

Preheat ............

400 degrees F (205C)

b. Disassembly. Refer to TM 10-3930-630-12

Interpass ..........

250 degrees F (121C)

and disassemble the mast. Refer to figure 3-14 for mast

Postheat ..........

None

components.

3-19

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |