|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 10-3930-630-12

adjuster assembly and remove adjuster assembly from

brake shoes.

(8) Remove pins securing cylinder links to

brake shoes and remove links.

(9) Disassemble the brake adjuster by

removing two screws (5, Fig. 4-73), nuts (6) and

washers (3 and 4). Separate slide assemblies (1) and

remove nylon washers (2).

c. Inspection.

(1) Inspect linings for wear, dirt, grease and

brake fluid.

(2) Clean linings to remove foreign matter.

(3) Inspect brake drums in wheels for cracks,

deep scratches and other defects.

(4) If linings are worn to less than 0.125 inch

(3.17 mm) or if linings are saturated with fluid or grease,

replace shoes.

(5) Inspect brake shoes for wear, cracks,

elongated holes and other damage.

(6) Inspect return springs for broken, nicked or

fatigued coils.

d. Installation.

CAUTION

TA034846

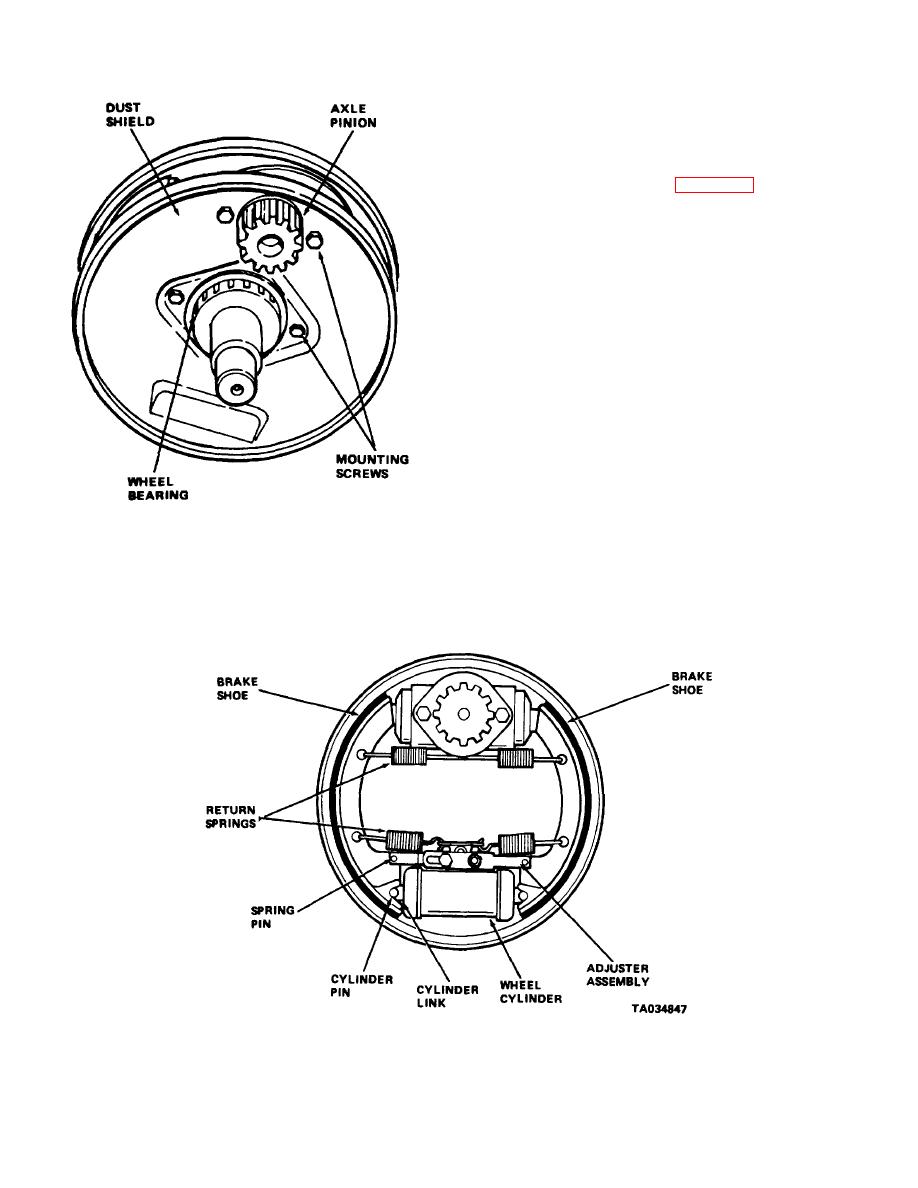

Figure 4-71. Service brake dust shield,

Brake shoes are free floating and self-

installed view.

adjusting. Check for obstructions during

installation that could interfere with

and lift brake shoes and attached adjuster assembly and

floating action.

cylinder links from backing plate.

(7) Using a brass drift, drive spring pins from

Figure 4-72. Service brake shoes, installed view

4-80

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |