|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 10-3930-630-12

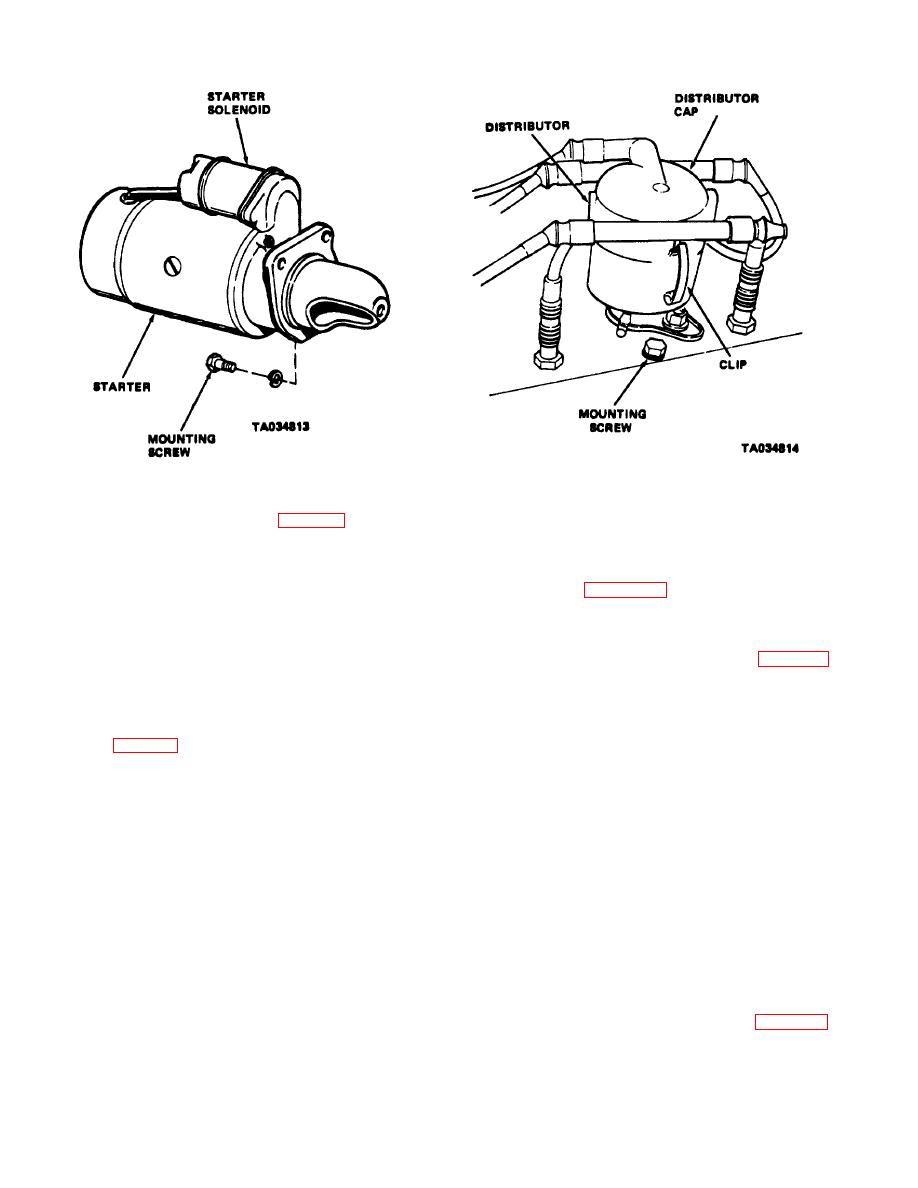

Figure 4-39. Distributor, installed view.

Figure 4-38. Starter, removal and installation

(3) Inspect interior of cap for burned or

(4) Support starter (fig. 4-38) and remove

worn contacts, carbon tracks and cracks.

Wipe

screws and lockwashers securing starter to flywheel

distributor cap with a clean cloth.

housing.

(4) Inspect breaker points for pitting and

(5) Carefully pull starter from housing and

wear. Refer to figure 4-40 and check breaker point gap.

remove from truck.

d. Installation.

Rotate cam to bring breaker lever to high point on cam.

Insert feeler gage between breaker points Gap should

(1) Lift starter (fig. 4-88) into position on

be 0.020 inches (0.50 mm) between points. If points

flywheel housing with starter drive in line with flywheel

require adjustment, loosen lockscrew (fig. 4-40) and

ring gear.

place screwdriver in adjusting slot. Move breaker lever

(2) Install screws and lockwashers to

until correct gap is obtained. Tighten lockscrew to hold

attach starter to flywheel housing. Tighten screws

adjustment. Correct dwell angle is 66 to 72.

securely.

(5) Apply a light coat of grease (GAA) to

(3) Check tap and connect wires to starter

distributor cam. Place a few drops of oil (OE/HDO) in

solenoid (fig. 4-38).

oil cup.

4-53.

Distributor

(6) Install dust seal, rotor and distributor

cap and secure cap with clamps

a. General. The distributor is mounted on the

(7) Remove prop and lower seat and

support into position above engine.

top of the cylinder head. High tension wires connect the

c. Removal

distributor to the spark plugs and coil A shaft, driven by

(1) Lift and tip seat forward and prop in

the engine, extends up to a coupling and drives the

open position.

distributor.

b. Service.

(2) Disconnect spark plug wires (2, fig. 4-

41) from distributor cap. Disconnect coil wire (1) from

(1) Lift and tip seat forward and prop in an

distributor cap. Disconnect primary lead from coil

open position.

(3) Remove screw (12) and lockwasher

(2) Disengage clips at sides of distributor

(18) and lift distributor, with clamp (14) attached, from

(fig. 4-89) and lift cap from distributor. Remove rotor

engine.

and dust seal

d. Disassembly.

(1) Disengage clamps (2, fig. 4-42) and

remove distributor cap (3) from distributor.

4-47

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |