|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 10-3930-630-12

b.

Service. Operator service for the engine is

to gain access to the muffler.

limited to checking the oil level in the crankcase and

adding oil to bring to operating level

pipe for evidence of holes and leakage. Check clamps

(1) With engine off, open right side panel

for security.

to gain access to oil level gage.

3-14.

Engine Assembly

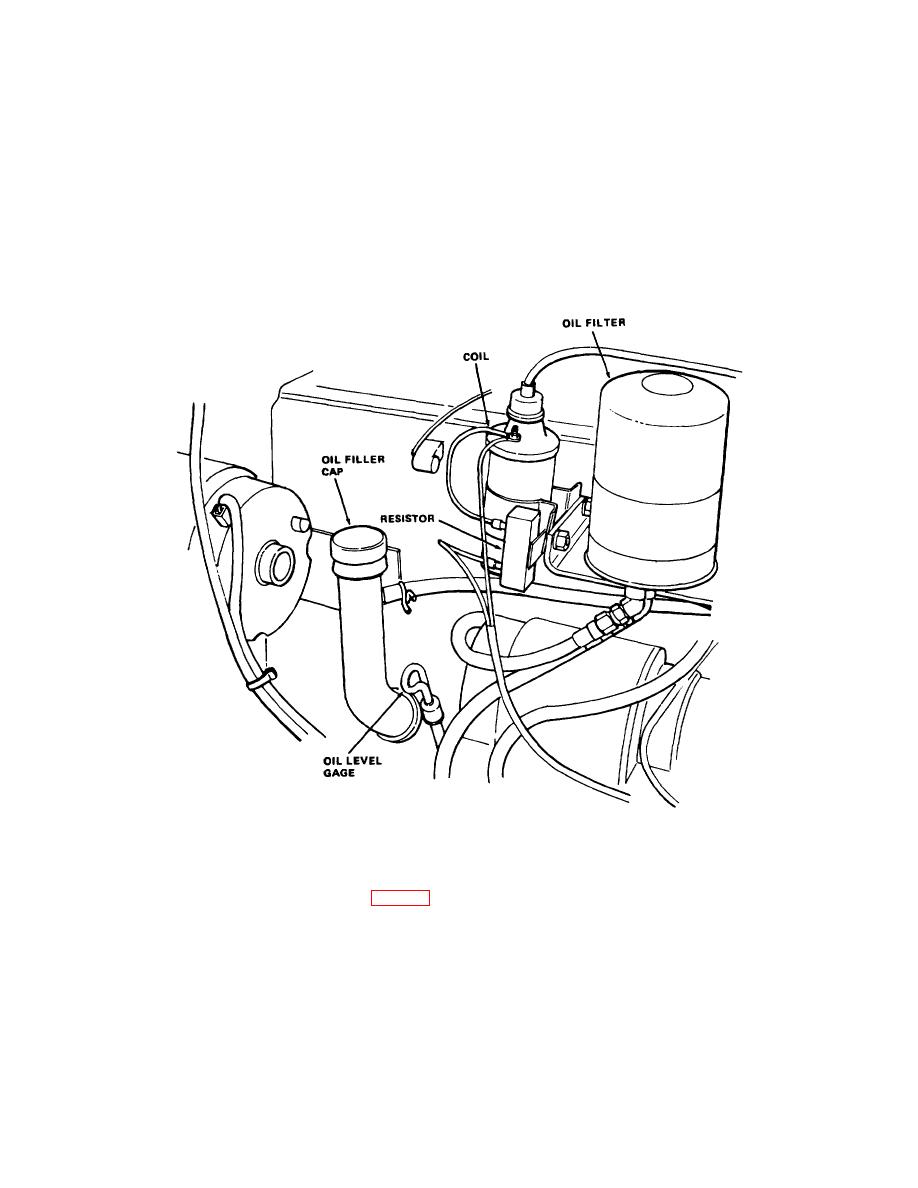

(2) Remove engine oil level gage (fig. 33)

and check oil level Oil level should be between the ADD

a. General The engine is mounted in a

and F marks on the gage.

compart- ment below the operator's seat. Open side

panels and tilt seat forward to gain access to the engine.

.

TA034772

Figure 3-3. Oil filler cap and level gage.

(3) To add oil remove filler cap (fig. 3-3)

axle to turn the truck. The tires are the solid rubbe-

and add oil Refer to current lubrication order for correct

cushion type.

b. Inspection.

grade of oil

(1) Inspect the tires for cuts, gouges and

3-15.

Wheels and Tires

other damage.

(2) Check the wheels for secure

a. General The front wheels of the truck are

mounting.

(3) When operating truck listen for

the drive wheels.

A propeller shaft connects the

unusual noises that could come from loose wheel

transmission to the drive axle.

Rear wheels are

mounting or worn wheel bearings.

mounted on the steering axle. A hydraulic cylinder,

actuated by turning the steering wheel, rotates the

steering

3-7

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |