|

|||

|

|

|||

|

Page Title:

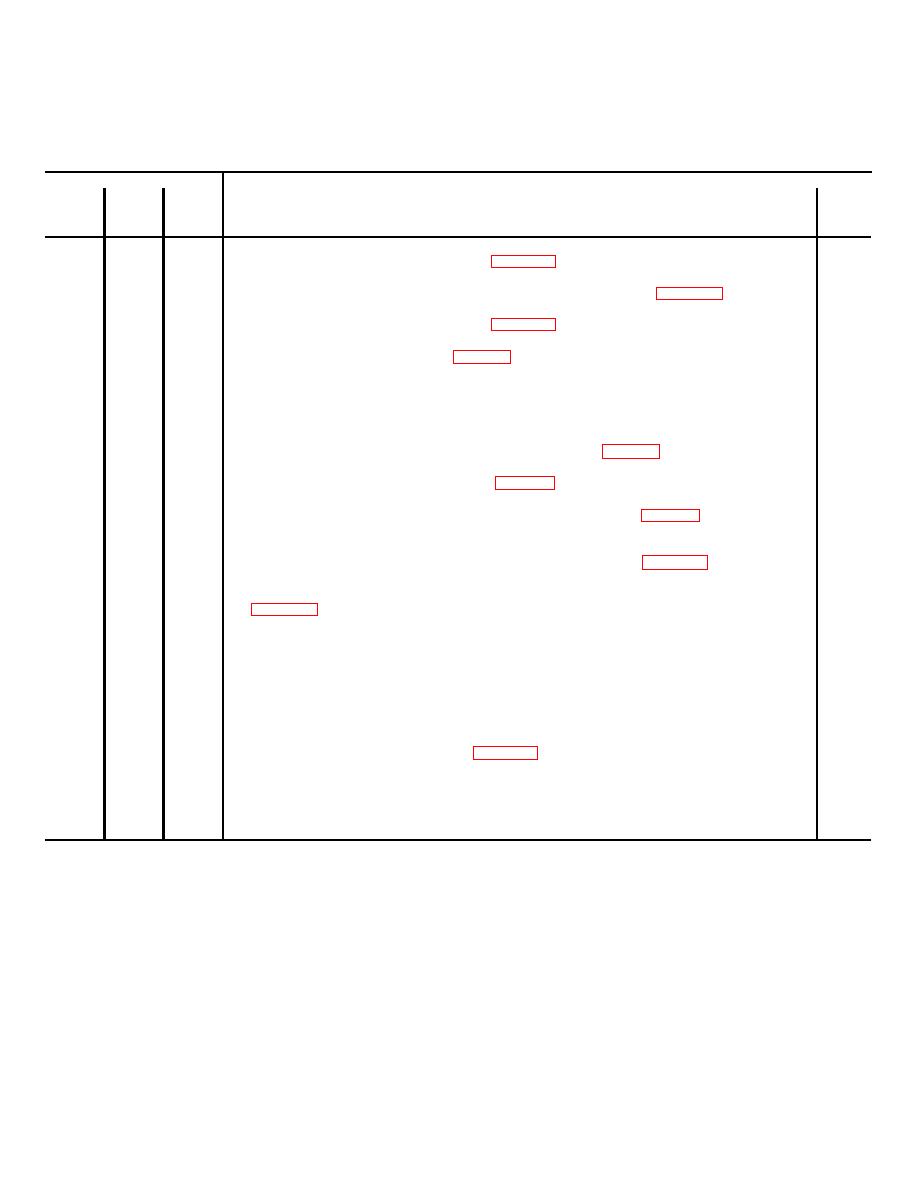

Table 3-1. Operator/Crew Preventive Maintenance Checks and Services - Continued |

|

||

| ||||||||||

|

|

TM 10-3930-630-12

Table 3-1. Operator/Crew Preventive Maintenance Checks and Services - Continued

B - Before Operation

D - During Operation

A - After Operation

Time required: 1.5

Time required: 0.9

Time required 1-2

Interval and sequence No.

Work

time

B

D

A

Items to be inspected Procedures

(M/H)

4

ENGINE

02

Check oil level and add oil if necessary (para 3-14).

5

TIRES

02

Check for imbedded material, check for gouges and other damage (para 3-15).

6

TRANSMISSION

02

Check oil level and add oil if necessary (para 3-16).

7

LIGHTS

0.1

Check lights for proper operation (para 2-2

8

HORN

0.1

Check horn for proper operation (para 2.2

9

FIRE EXTINGUISHER

0.1

Inspect for broken seal and correct pressure.

10

INSTRUMENTS

0.1

Check that all instruments indicate within required ranges (para 3-9

11

CONTROLS

02

Check that controls perform as required (para 2-2).

12

BRAKES

02

Check parking brake and service brake to assure safe operation (para 2-2).

13

AIR CLEANER

0.1

Check air cleaner indicator. Indicator should show green in window. If indicator shows red

locked in up position, check air filter element and reset indicator (para 3-10).

14

HYDRAULIC SYSTEM

Check hydraulic filter indicator. Indicator should show green band in line with indicating line

15

UNUSUAL NOISES AND VIBRATION

02

Listen for unusual noises and check for excessive vibration. If present, shut off truck and

report to organizational maintenance

16

FUEL LEVEL

02

Fill fuel tank.

17

TRANSMISSION

02

Check oil level Add oil as necessary (para 3.16).

18

HYDRAULIC RESERVOIR

Check oil level Add oil as necessary (para 3-18).

19

FAN BELT

02

Check for proper adjustment, three-eights of an inch between pulleys If belt is worn or

frayed, notify organizational maintenance.

20

TIRES

0.4

Remove imbedded material. Check for gouge and other damage.

Section III. OPERATOR'S TROUBLESHOOTING

3-5.

General

b.

This manual cannot list all malfunctions that

may occur, nor all tests or inspections and corrective

a.

actions. If a malfunction is not listed or is not correctly

This

section

contains

troubleshooting

listed by corrective actions, notify organizational

information for locating and correcting most of the

maintenance personnel

operating troubles which may develop in the fork lift

truck. Each malfunction for an individual component,

3-6.

Operator's Troubleshooting

unit or system is followed by a list of tests or inspections

which will help you to determine probable causes and

corrective actions to take. You should perform the

Malfunctions which may occur are listed in table 32.

test/inspections and corrective actions in the order

Each malfunction stated is followed by a list of tests and

listed.

inspections within the recommended corrective action.

3-2

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |