| |

(2)

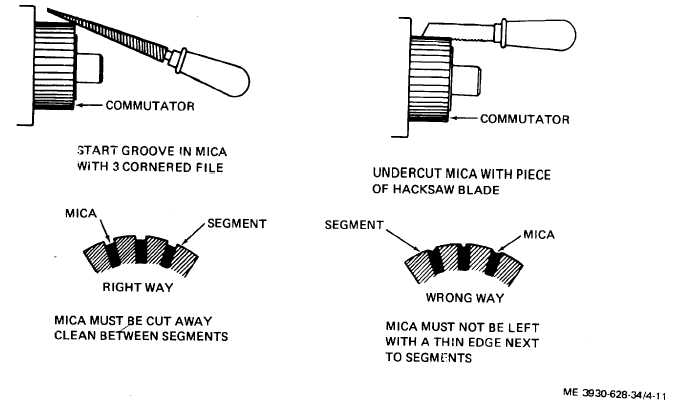

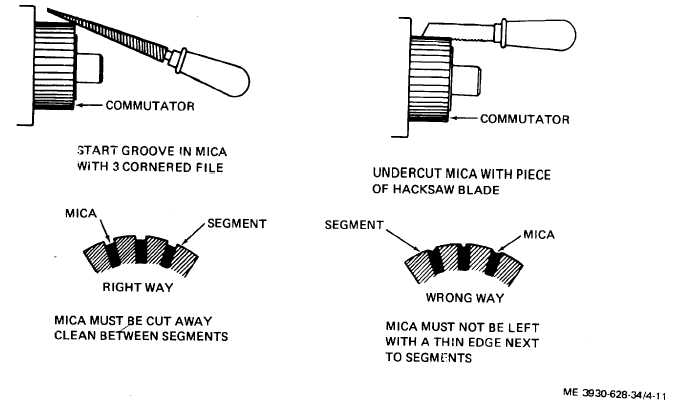

Undercutting mica. After resurfacing the

commutator, undercut the mica to a depth of 0.025 to

0.032 inch below the commutator surface using a power-

driven undercutting tool (fig. 4-10). If a power-driven

tool is not available, the mica may be undercut by hand

as shown in figure 4-11.

Note. Use care in undercutting. Do

not widen the commutator slots by

removing metal from the segments,

and do not leave a thin edge of mica

next to the segments. Figure 4-11

illustrates good examples of good

and bad undercutting.

Figure 4-10. Undercutting mica using a power-driven

tool.

Figure 4-11. Undercutting mica using an alternate hand method.

(3)

Polishing the commutator. After the mica

has been undercut, remove all copper and mica particles

with compressed air. Polish the cornmutator in a lathe

with No. 2 / 0 sandpaper while the armature is rotating at

a speed of 1500 rpm.

b.

Repair of the Remaining Parts.

4-7

|