|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 10-3930-628-12

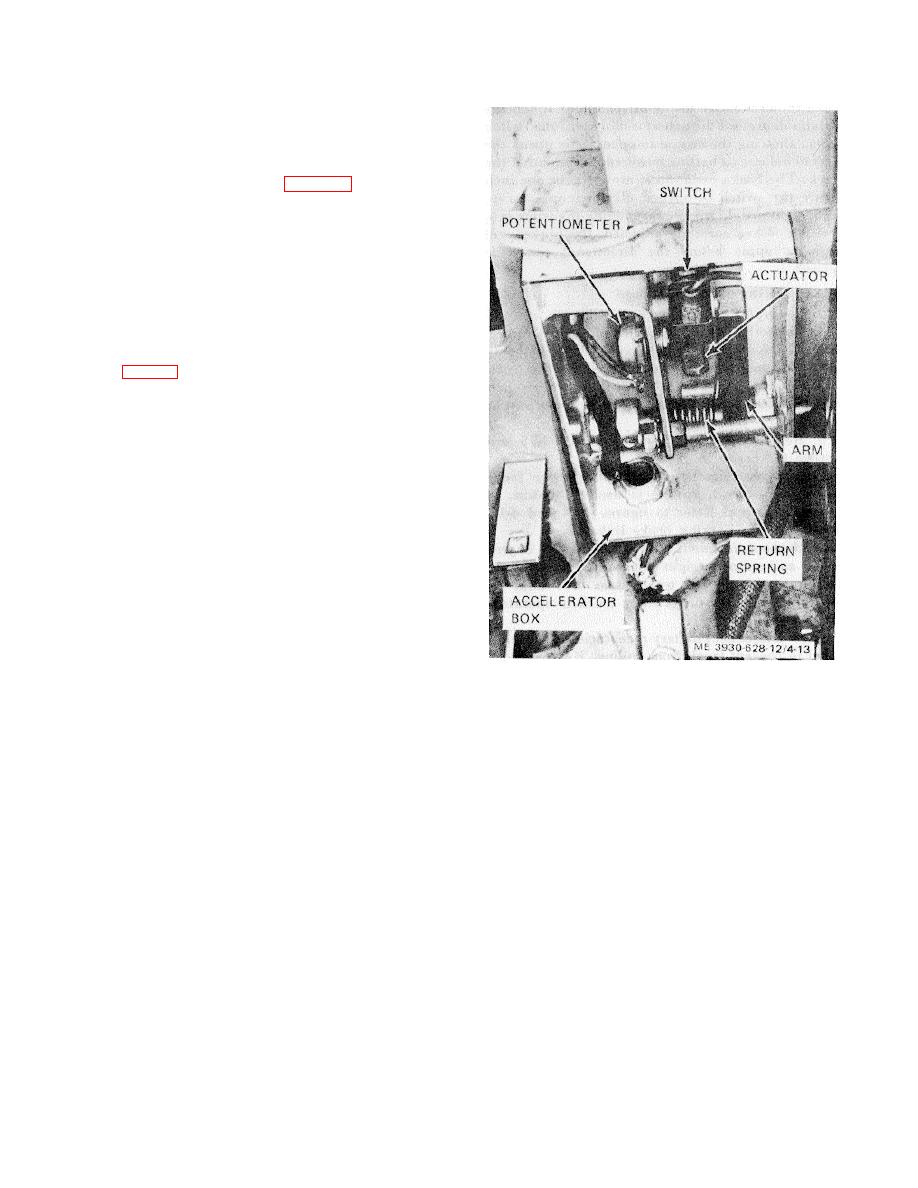

c. Accelerator Control. This control is located

on the front part of the frame to the left of the steering

column. Remove the cover from the box to gain access

to the components. Inspect components as follows:

(1) Check potentiometer (fig. 4-13) for secure

mounting and operation.

(2) Check switch, actuator, and arm for proper

operation. Depress accelerator and observe operation of

switch and potentiometer.

(3) Inspect.

return spring for cracks and

damage. Operate accelerator and observe action of

return spring.

d. Forward and Reverse Switch. The forward

and reverse switch is mounted in a box below the

instrument panel. To inspect the switch, remove cover

from box (fig. 4-1). Inspect switch for secure wiring and

damage. Install cover on box.

e. Harness Wiring.

Inspect the wiring

harnesses for damage, broken wires, damaged

insulation, loose terminals, and insecure mounting.

Repair and tighten terminals. Tape or cover damaged

insulation. Connect broken wires, if possible. Tighten

mounting clamps and ties, if necessary.

Figure 4-13. Accelerator control box, installed view.

Section IX. BRAKES

4-31.

General

seat opens the switch and removes power from all

a. Brakes on the fork lift truck consist of two

electrical circuits.

systems: a seat operated parking brake on the drive

c. The service brakes are hydraulically

motor shaft and service brakes on the two front wheels.

actuated through a pedal and master cylinder.

b. The parking brake is a dual-shoe

Depressing the pedal operates the master cylinder

mechanical operated type. Actuation of the brake is ac-

sending hydraulic pressure to the wheel cylinders. The

complished through a linkage connected to the hinged

wheel cylinders are the double end type and hydraulic

operator's seat. When the operator leaves the seat or

pressure extends the ends of the cylinder, pivoting the

stands up, removing his weight from the seat, the brake

brake shoes against the brake drum inside the wheel.

is applied. A spring at the lower end of the linkage

The pressure in the master cylinder also closes the

expands and moves the brake actuating lever which

stoplight switch and operates the stoplight. When the

forces the brake shoes against brake drum. This

pedal is released, springs return the pedal and brake

pressure keeps the shaft from rotating, locking the front

shoes to the released position.

wheel and holding the truck in position. A seat switch is

d. A brake interlock switch is employed in the

actuated by the linkage when the seat is raised or

electrical system to reduce the amount of load on the

lowered. The switch is closed when the seat is down.

drive motor and conserve battery current. The switch is

Raising the

a normally open switch and is held closed

4-15

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |