|

|||

|

|

|||

|

Page Title:

Section VII. RADIO INTERFERENCE SUPPRESSION |

|

||

| ||||||||||

|

|

TM10-3930-628-12

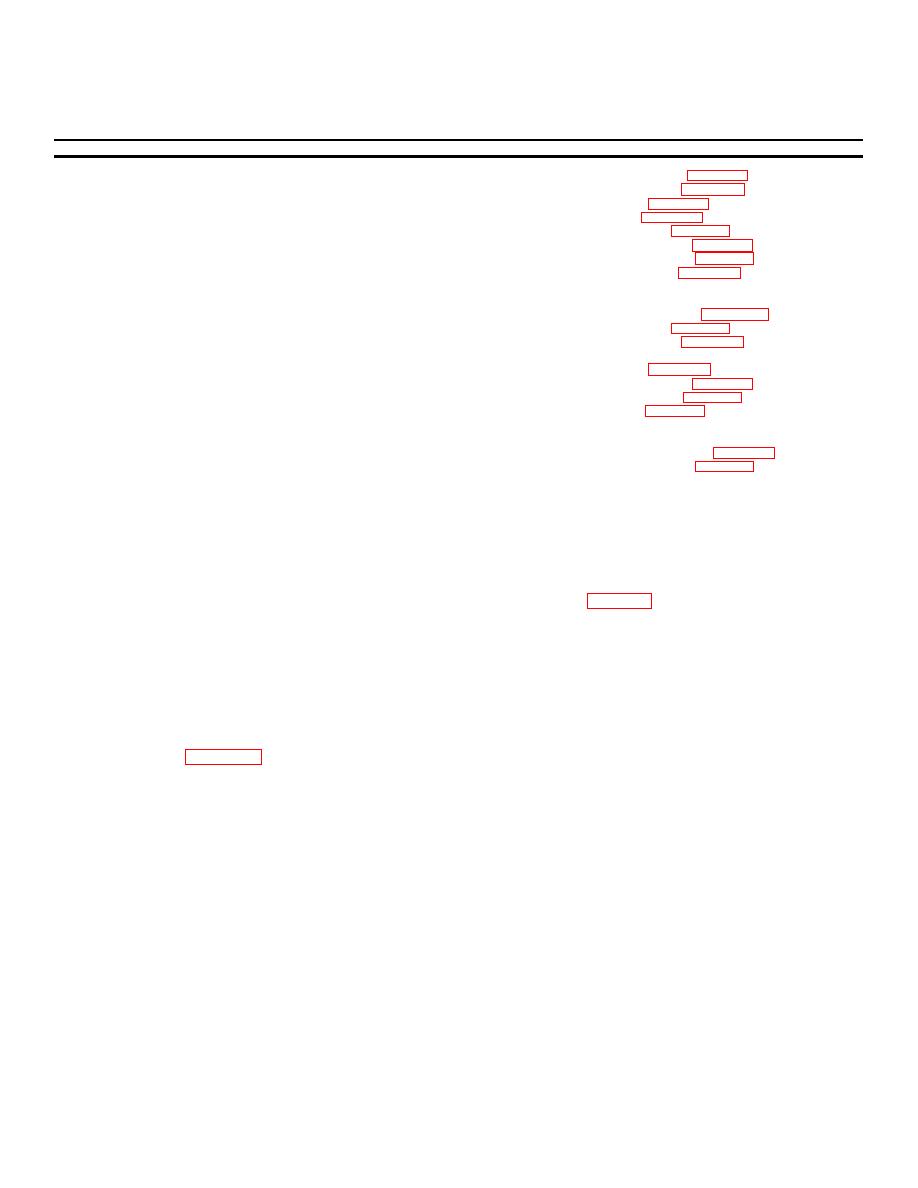

Chart 4-1. Troubleshooting (Continued)

Malfunction

Probable cause

Corrective action

8.Service brakes drag-Cont'd

b. Weak or broken return spring.

b. Replace return spring (para 4-33).

c. Brake linings not fitted properly.

c. Replace brake shoes (para 4-36).

d. Wheel bearing loose.

d. Adjust bearing (para 4-39)

9.

Brake pedal soft or sponge.

a. Air in system.

a. Bleed system (para 4-35).

b. Inadequate oil supply

b. Fill master cylinder (para 4-34)

c. Defective wheel cylinder.

c. Replace wheel cylinder (para 4-37)

10. Brake peal hard to depress.

a. Improperly adjusted pedal or linkage

a. Adjust pedal free travel (para 4-33).

d. Brake lining glazed.

b. Replace brake shoes (para4-37).

11. Excessive pedal travel required to

a. Air in system.

a. Pump pedal several times. If

pressure builds up to normal travel,

bleed brake

system (para 4-35).

Truck pulls to one side when brakes

b. Inadequate oil supply.

b. Fill master cylinder (para 4-34)

brakes are applied

a. Fluid or grease on brake lining.

a. Replace brake shoes (para 4-34).

are applied.

b. Brake shoe return spring defective.

b. Replace spring (para 4-37).

c. Defective wheel cylinder.

c. Replace wheel cylinder (para 4-37).

d. Wheel bearing loose.

d. Adjust wheel bearing (para 4-39).

13. Parking brake dragging.

a. Linkage improperly adjusted.

a. Adjust linkage (para 4-32).

b. Defective parking brake.

b. Refer to direct and general support

maintenance personnel.

14. Steering mechanism not operating properly. a. Steering mechanism not adjust properly. a. Adjust steering mechanism (para 4-42).

b. Incorrect wheel alignment

b. Adjust wheel alinement (para 4-42).

Section VII. RADIO INTERFERENCE SUPPRESSION

4-16. General Methods to Obtain Proper

4-18.

Replacement of Suppression Components

a. Remove drip Fan from beneath truck.

Suppression

b. Remove two screws and lock washers

Essentially, suppression is obtained by providing a low,

attaching drive motor to drive axle and remove two

resistance path to ground for stray currents. The

bonding straps fig. 4-37).

methods used include grounding the frame with bonding

c. Install bonding straps on flange and secure

straps, and using capacitors and resistors.

with two screws and lock washers.

4-17. Interference Suppression Components

d. Install drip pan.

Radio interference suppression in the fork lift truck

is obtained through the use of two bonding straps

Section VIII. ELECTRICAL SYSTEM

control and a speed control. The forward and reverse

4-19.

General

lever allows the operator to select the direction of travel.

a. Refer to figure 1-3 for a schematic diagram

Speed control of the truck is maintained through a foot

of the electrical system.

pedal or accelerator.

b. The main components of the -electrical

d. A key switch on the instrument panel opens

system are the battery, which supplies the electrical

and closes the circuits to operate the truck. An hourmeter

power; the controls, %which control and distribute the

installed on the instrument panel records elapsed running

power: the instruments and the electric motors, which

time of the truck. A green light on the panel glows when

convert the electrical energy. into mechanical energy.

the key switch is in the "on" position.

The motors power the drive axle and hydraulic pump.

e

.All circuits on the truck are protected by

c. Operational controls consist of a directional

fuses.

4-4

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |