|

|||

|

|

|||

|

Page Title:

Inspecting and Servicing the Equipment. |

|

||

| ||||||||||

|

|

TM10-3930-628-12

CHAPTER 2

OPERATING INSTRUCTIONS

d. Remove any preservative compound that

2-1.

Inspecting and Servicing the Equipment.

has been sprayed on metal surfaces with cleaning

a. When a truck is received by the using

compound, solvent (Fed. Spec. P-D-680) and dry

organization it must be serviced to prepare it for

thoroughly.

operation. The services required are described in

Note. Preservative compound is not a lubricant. Take

b. Carefully inspect the truck for any signs of

special care to completely remove the compound from all

dents or damage that may have occurred during

wearing surfaces.

shipment. Pay particular attention to sheet metal panels

e. Fill battery with electrolyte to five-eighths of

and controls and instruments.

an inch above the plates. Check specific gravity of

c. Remove tape, paper and other packing

electrolyte as prescribed in TM 9-6140-200-15.

materials. Remove forks from truck by removing

Warning: When servicing battery, do not

smoke or use flame in the vicinity. Batteries generate

hydrogen, a highly explosive gas. f. Lubricate the truck in

accordance with the current lubrication order.

g. Fill hydraulic reservoir with proper grade of

oil. Refer to current lubrication order.

2-2.

Installation

of

Separately

Packed

Components

a. Components. The only components not

already installed are the forks and the fire extinguisher.

b. Fire Extinguisher. Remove separately

packed fire extinguisher and install in bracket on

instrument panel. Be-certain bracket clamp locks

properly to secure fire extinguisher in position.

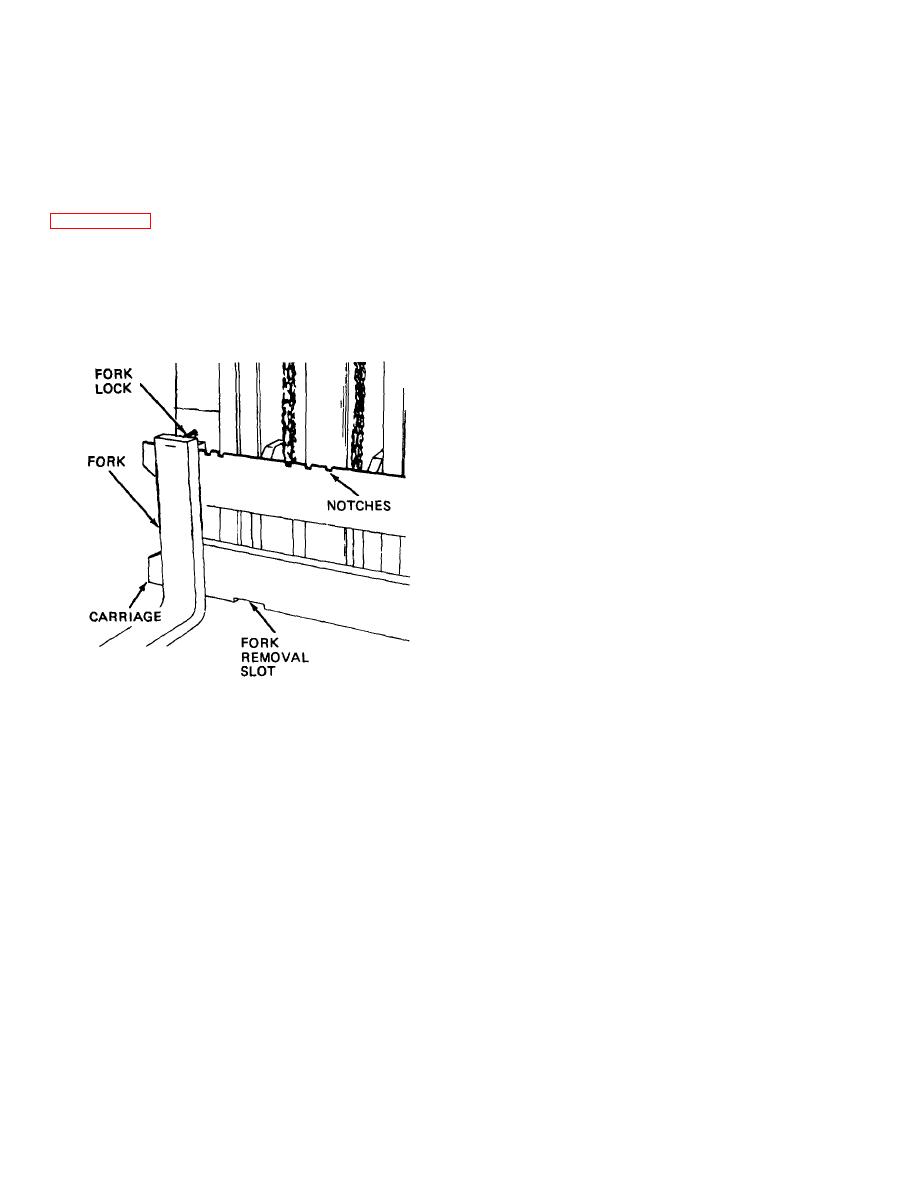

INSTALLATION

1. RELEASE FORK LOCK BY TURNING

POINT UP.

2. SLIDE FORK IN LINE WITH SLOT ON

CARRIAGE. LIFT FRONT OF FORK UP

AND SLIDE INTO POSITION.

3. TURN POINT OF FORK LOCK DOWN TO

LOCK FORK IN NOTCH ON CARRIAGE.

REMOVAL

1. TURN POINT UP TO RELEASE FORK

LOCK.

2. SLIDE FORK IN LINE WITH SLOT ON

CARRIAGE. LIFT FRONT OF FORK UP

AND REMOVE FROM CARRIAGE.

ADJUSTMENT

1. RELEASE LOCK.

2. SLIDE FORK IN LINE WITH NOTCH AND

LOCK IN POSITION.

ME 3930-628-12/2-1

Figure 2-1. Removing, installing, or adjusting carriage

forks.

2-1

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |