|

|||

|

|

|||

|

Page Title:

Chapter 8. REPAIR OF DRIVE AXLE |

|

||

| ||||||||||

|

|

CHAPTER 8

REPAIR OF DRIVE AXLE

Note. It is often difficult to determine

8-1. Description

a. The drive axle consists of a differential with its

if trouble originates in differential,

separate housing, two axle shafts which transfer power

axle, or transmission. Refer also to

from the differential to the final drives at the wheels, and

troubleshooting chart (table 2-2) for

the final drive system which transfers power from the

additional troubleshooting proce -

axle shafts to the wheels, which are mounted on tapered

dures.

roller bearings. Each shaft has an individual housing

which bolts to the differential housing and which acts to

8-2. Power Axle Overhaul

hold the differential positioned in its housing.

b. The pinion gear of the transmission engages the

(1) Remove mast.

ring gear of the differential when the transmission is

(2) Jack up truck frame high enough to insure

attached to the differential housing. Tooth contact and

crawl space under vehicle and securely install blocking

backlash are determined by selective fitting of shims at

under frame and under engine.

assembly. The adjustment technique is explained in this

chapter.

before beginning disassembly.

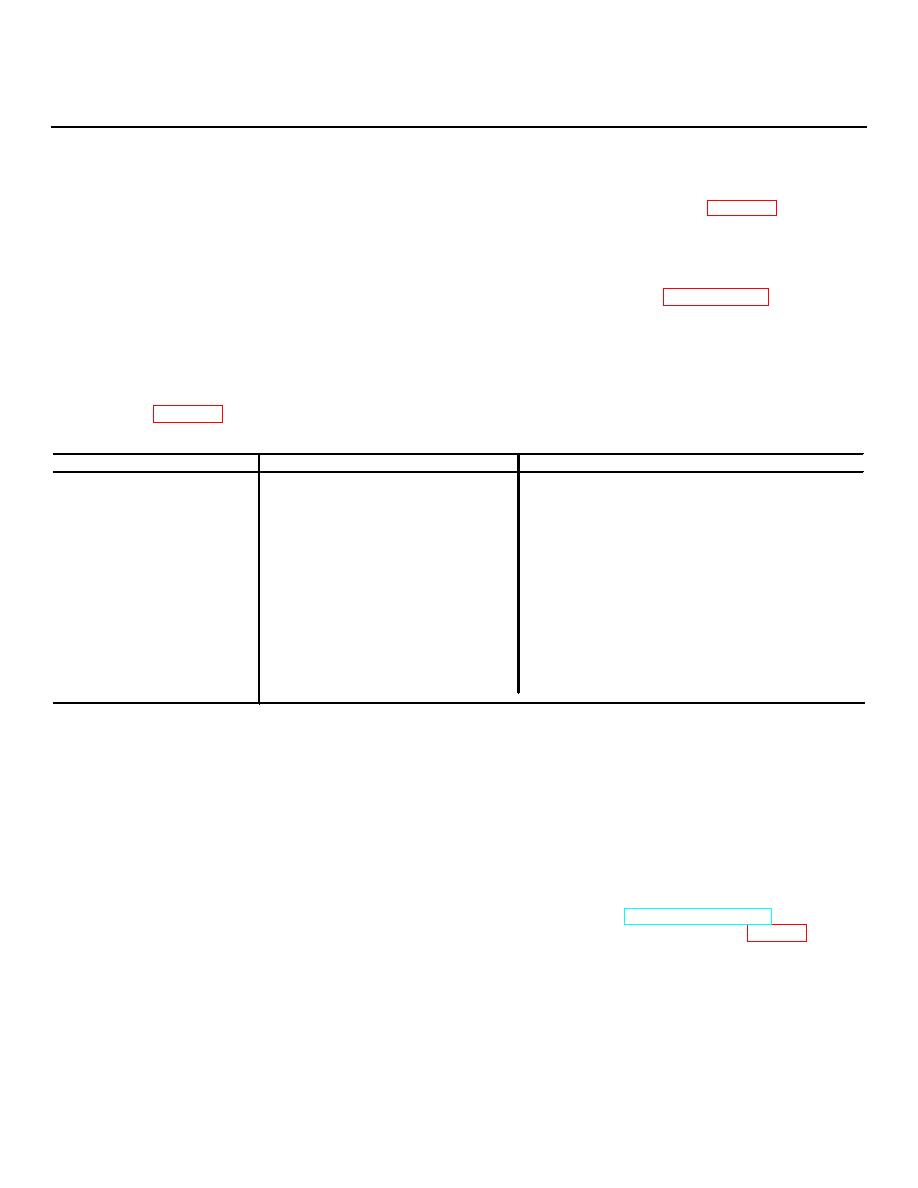

Table 8-1. Troubleshooting Chart, Power Axle

Malfunction

Probable cause

Corrective action

1.

Excessive noise in drive axle

a.

improper or insufficient lubricant.

a.

Refer to L. O. 10-3930-627-20.

b.

Worn or damaged parts.

b.

Overhaul axle.

c.

Improper engagement of pinion and

c.

Adjust shimming of axle parts.

ring gear.

d.

Improper engagement between

d.

Adjust shimming between trans-

transmission output shaft and ring

mission and differential housing.

gear.

2.

Excessive backlash in axle.

a.

Worn pinion, ring gear, or differential

a.

Overhaul axle.

b.

improper engagement of pinion and

b.

Adjust shimming of axle parts.

ring gear.

3.

Axle whines at certain speeds.

a.

Improper engagement of pinion and

a.

Adjust slimming of axle parts.

ring gear.

b.

Worn pinion, ring gear, or differential

b.

Overhaul axle.

(3) Drain transmission. Support transmission on

(9) Remove assembled transmission and drive

dolly.

Disconnect shift linkage from transmission;

axle by pulling straight out from engine and rolling it out

disconnect hydraulic coolant lines to radiator; drain oil

from under truck.

from torque converter; remove flywheel access cover

(10) Block up under rear end of power axle so that

plate and remove screws attaching torque converter to

wheels clear ground and support transmission with hoist.

flywheel. Disconnect leads at neutral safety switch.

Remove cap screws, nuts, and lock washers that secure

(4) Disconnect parking brake linkage from brakes

transmission case to lower differential housing, and

at wheels.

remove transmission by pulling straight away from axle.

(5) Disconnect hydraulic brake lines from brake

b. Disassembly of Axle.

cylinders at wheels.

(1) Remove screws that secure wheels to axle

(6) Remove drive axle collars from frame.

and remove wheels, (TM 10-3930-627-12).

(7) Remove cap screws and lock washers that

(2) Remove two spring pins (6, fig. 8-1) parking

secure transmission housing to engine flywheel housing.

brake rods (5), cotter pins (3), nuts (4) and levers (2).

(8) Attach sling to front lift eyes at frame and lift

(3) Remove brake tube assemblies (8 and 9),

frame to clear axle.

screws, nuts and washers (15, 16, 17 and 18), fittings

8-1

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |