|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

brushes in holders after alternator is assembled. This

6-7. Starting Motor Disassembly and Inspection

will allow brushes to drop on slip rings.

6-4. Alternator Test and Installation

Do not disassemble further than necessary to locate

After installation, check and if necessary adjust

damaged parts.

regulator, TM 10-3930-627-12.

b. Check for worn brushes (4). Replace if worn to half

6-5. Starting Motor Removal and Installation

the length of a new brush from stock. Make sure brush

See TM 10-3930-627-12.

holders (6) are clean and that brushes are not binding in

holders. Check tension of brush spring (8); it must be

6-6. Starting Motor Test

35 ounces minimum.

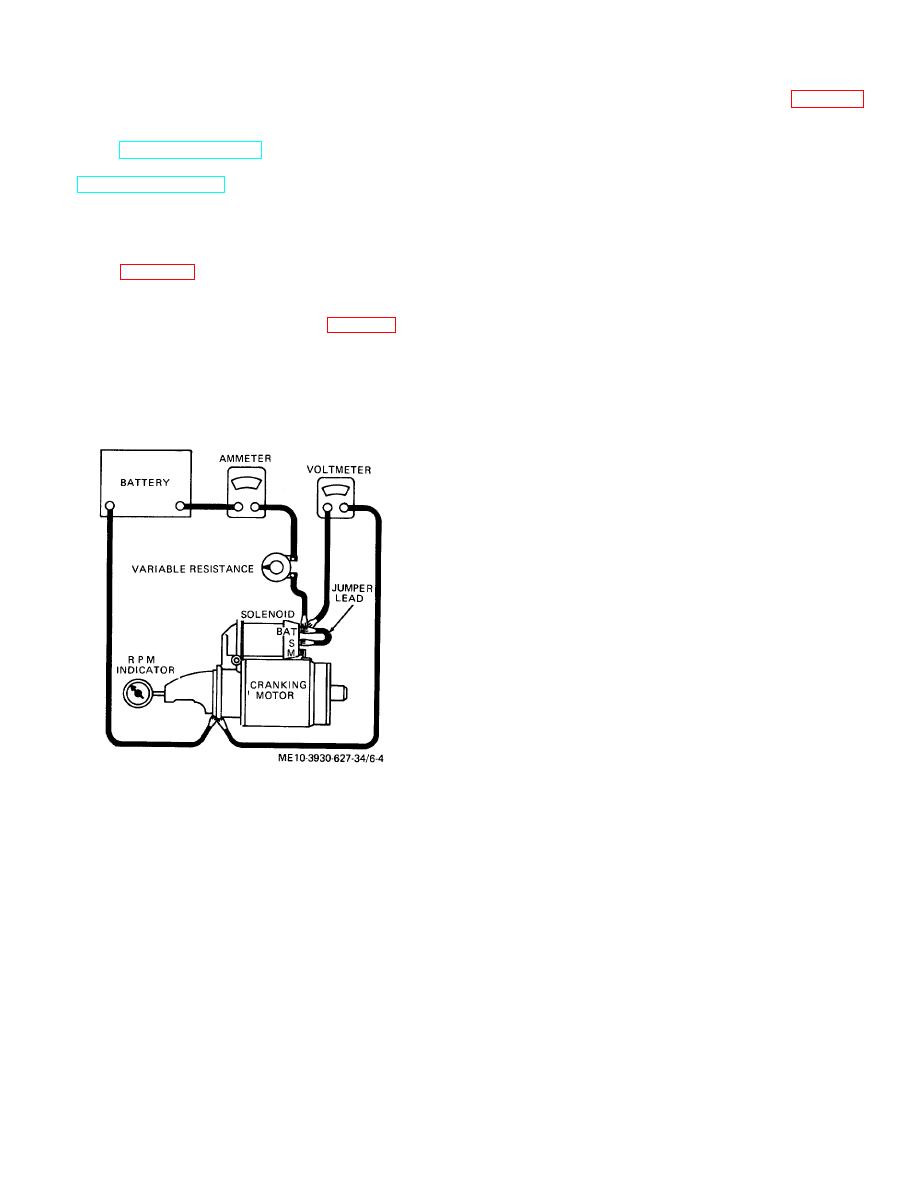

a. Connect starting motor in series with fully-charged,

c. Check armature (15) for shorting by using a

12-bolt battery, an ammeter capable of reading several

growler. Shorts are sometimes caused by brush or

hundred amperes, and a variable resistor in a setup as

copper dust between copper commutator bars.

shown in figure 6-4. Connect negative battery lead to

Undercut commutator insulation to eliminate these

starting motor frame.

shorts.

d. Check for open armature windings by checking for

frame and to motor terminal as shown in figure 6-4.

loose connections between commutator risers and ends

of windings. Poor connections cause arcing and burning

of commutator. If commutator bars are not too badly

is indicated on voltmeter.

burned, resolder leads to bars and turn down

commutator in lathe. Undercut commutator insulation to

tachometer. Current draw must be 50 to 80 am-peres.

1/32 inch lower than commutator bar surface.

Speed must be 5500 to 10, 500 rpm.

e. Check for grounds in armature, using test lamp. If

lamp lights when one probe is placed on commutator

and the other is on shaft or core, armature is grounded

and will need replacement.

f. Check field coils for grounds with test lamp.

Connect one probe of test lamp to field frame and other

to field connector.

If lamp lights, field coils are

grounded and must be replaced.

g. Check field coils (39 and 40) for opens with test

lamp. Apply probes to ends of field coils. If lamp fails

to light, field coils are open, and must be replaced.

Figure 6-4. Starting motor test setup.

6-5

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |