|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

3-16. Water Pump,

Removal,

Inspection

and

Installation

3-17. Cooling System Maintenance

a. General Information. Engines are shipped with a

cooling system protector pellet in the water outlet

header, which should not be removed, but allowed to

dissolve in the cooling system. This pellet is a film

covered cartridge, all of which completely dissolves in

the cooling water with proven results as a water

conditioner and rust inhibitor. It can be used with all

types of antifreeze during cold weather operation. The

appearance of rust in the radiator or coolant is a warning

that the corrosion inhibitor has lost its effectiveness and

the system should be cleaned as explained below before

adding fresh coolant. In some areas, the chemical

content of the water is such, that even the best of rust

inhibitors will not protect the cooling system from the

formation of rust and scale. There are instances where

this corrosive element has eaten holes through cast iron

parts such as water pump impellers and bodies. This

condition is caused by electrolysis taking place in the

parts involved. Where these conditions exist, water

filters should be incorporated in the assembly to remove

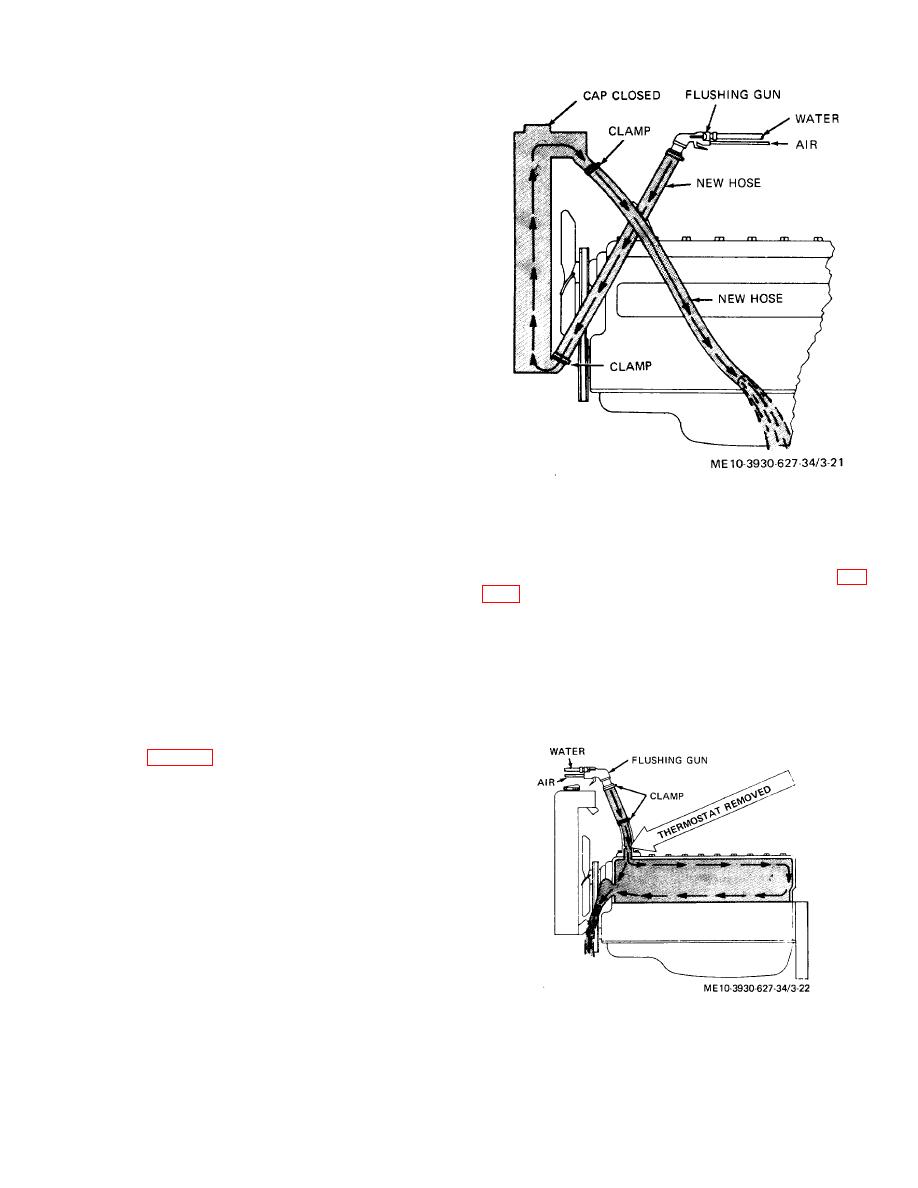

Figure 3-21. Reverse flushing radiator.

these troublesome elements and offset the electrolytic

action. Whenever a cooling system is badly rust

c. Engine Reverse Flushing.

clogged as indicated by overflow losses or abnormally

(1) Remove the thermostat.

high operating temperatures, corrective cleaning by

(2) Clamp the flushing gun in the upper hose (fig.

reverse flow flushing will most effectively remove the

heavy deposits of sludge, rust and scale. The reverse

(3) Partly close the water pump opening to fill the

flow flushing should be performed immediately after

engine jacket with water before applying the air.

draining the cleaning solution and it is advisable to flush

(4) Follow the same procedure outlined above for

the radiator first, allowing the engine to cool as much as

the radiator by alternately filling the water jacket with

possible.

water and blowing it out with air (80 pounds pressure)

b. Radiator Reverse Flushing.

until the flushing stream is clear.

(1) Disconnect the hoses at the engine.

(2) Put radiator cap on tight.

(3) Clamp the flushing gun in the lower hose with

a hose clamp (fig. 3-21).

(4) Turn on the water and let it fill the radiator.

(5) Apply air pressure gradually to avoid radiator

damage.

(6) Shut off the air, again fill the radiator with

water and apply air pressure. Repeat until the flushing

stream runs out clear.

Figure 3-22. Reverse flushing engine.

3-16

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |