|

|||

|

|

|||

|

Page Title:

Table 2-2. Troubleshooting Chart |

|

||

| ||||||||||

|

|

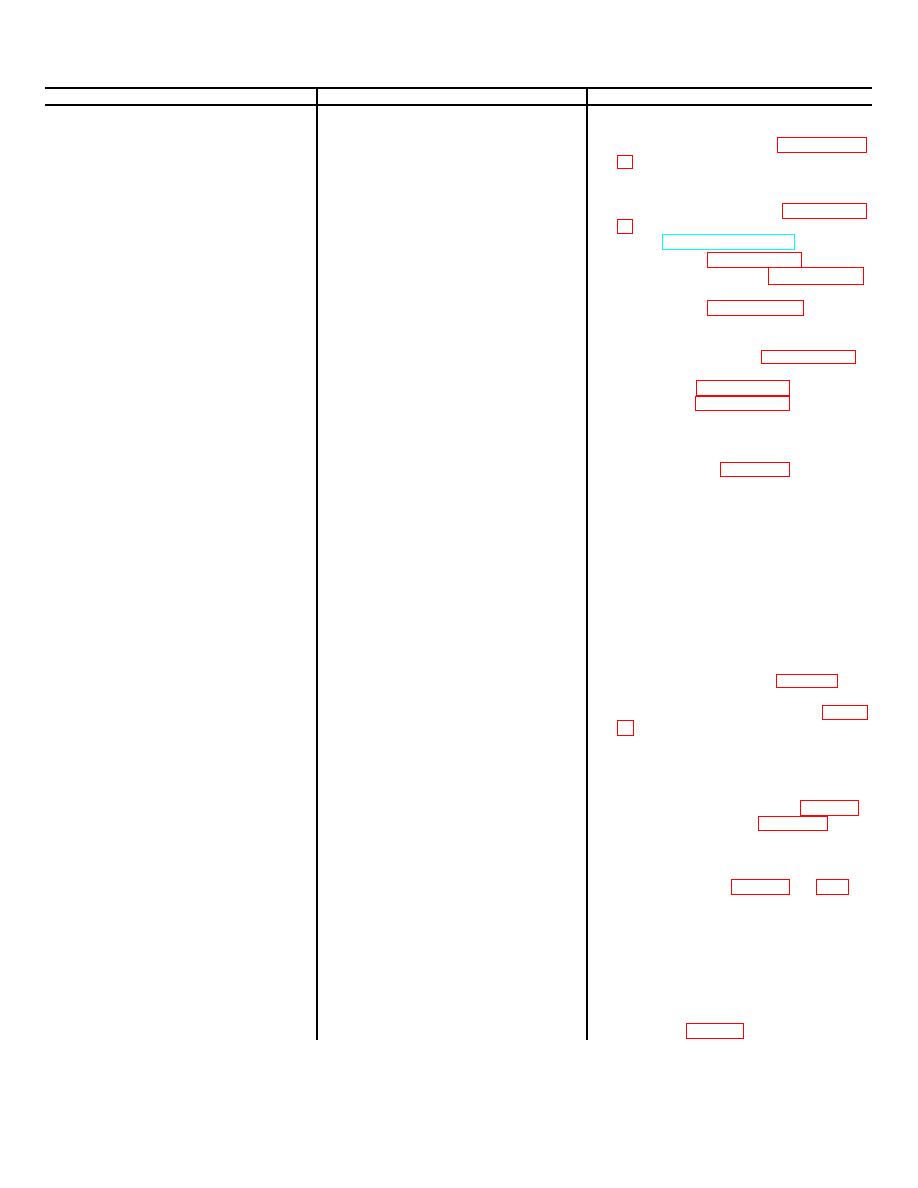

Table 2-2. Troubleshooting Chart

Malfunction

Probable Cause

Corrective Action

ENGINE

1. Starting motor will not crank engine

a. Replace cables.

a.

Defective cables.

when starter button is pressed.

b.

Incorrectly adjusted or defective

neutral safety switch.

7b.

2. Engine will not turn, starting motor

a.

Stripped starting motor drive.

a. Replace starting motor.TM 10-3930-627-

turns.

12.

b.

Stripped flywheel ring gear.

3. Engine cranks but will not start.

a. Ignition failure.

a. Refer to TM 10-3930-627-12.

b. Improper valve timing.

4. Engine sluggish, misses, backfires.

a. Burned or stuck valves.

b. Valves out of time.

c. Distributor advance not operating

c. Clean and adjust or replace as

properly.

necessary.

d. Sticky valves or valves not sealing

properly.

e. Valve timing incorrect.

5. Engine overheats.

Improper valve timing.

Time valves, paragraph 3-7c.

ENGINE NOISES

1. Sharp ping.

Excessive carbon deposits.

Clean carbon from combustion chamber

and top of piston.

2. Sharp hollow slap when starting

Worn pistons.

Overhaul engine. Chapter 3.

engine.

3. Continuous knock timed with engine

a. Loose piston pins.

a. Overhaul or replace engine.

rpm.

b. Loose connecting rods.

b. Overhaul or replace engine.

4. Dull, heavy pounding timed with

Worn or burned out main bearings.

Overhaul or replace engine.

engine rpm.

5. Continuous squeal or squeak.

Lack of lubrication at alternator, water

Lubricate as appropriate.

pump or distributor.

TRANSMISSION

1. Oil leakage.

Defective gaskets or seals.

Replace defective items as ap-propriate.

2. Coolant leakage.

a.

Worn or damaged hoses.

a.

Replace hoses, TM 10-3030-627-12.

b.

Loose fittings

b.

Tighten or replace as necessary.

3. High stall speed.

a.

Low oil level.

a.

Add oil to proper level.

b.

Low converter pressure.

b.

Check converter pressure (para 7-6) and

if low, check main pressure regulating

valve, and cooler bypass valve (fig. 7-

Overhaul transmission as needed.

c. Slipping clutch.

c.

Actuate other clutch to verify slipping of

particular

clutch

being

checked.

Observe main pressure at clutch lines

to determine if within limits (para 7-6).

Overhaul if necessary, Chapter 7.

d. Foaming oil due to:

1.

Adjust oil level.

1. Too low or too high oil level.

2. Water in oil.

2.

Drain, flush and refill transmission.

3. Air leak on intake side of pump.

3.

4. Improper oil.

4.

Change to specified oil.

4. Continuously high oil temperature.

a. See 3d. above.

b. Engine cooling system inoperative.

b. Check radiator cooling level. Eliminate

restricted water or oil flow through

cooler.

c. Severe service vehicle operation.

c. Operate away from stall more frequently.

d. Low oil flow through converter.

d. Converter pressure regulator valve stuck

in near closed position. Remove and

free valve (para 7-8).

2-4

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |