|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

Section VI. TROUBLESHOOTING

may occur are listed in table 4-2. Each malfunction

4-12. General

stated is followed by a list of probable causes of the

This section provides information useful in diagnosing

trouble and the recommended corrective action.

and correcting unsatisfactory operation or failure of the

forklift truck and its components. Malfunctions which

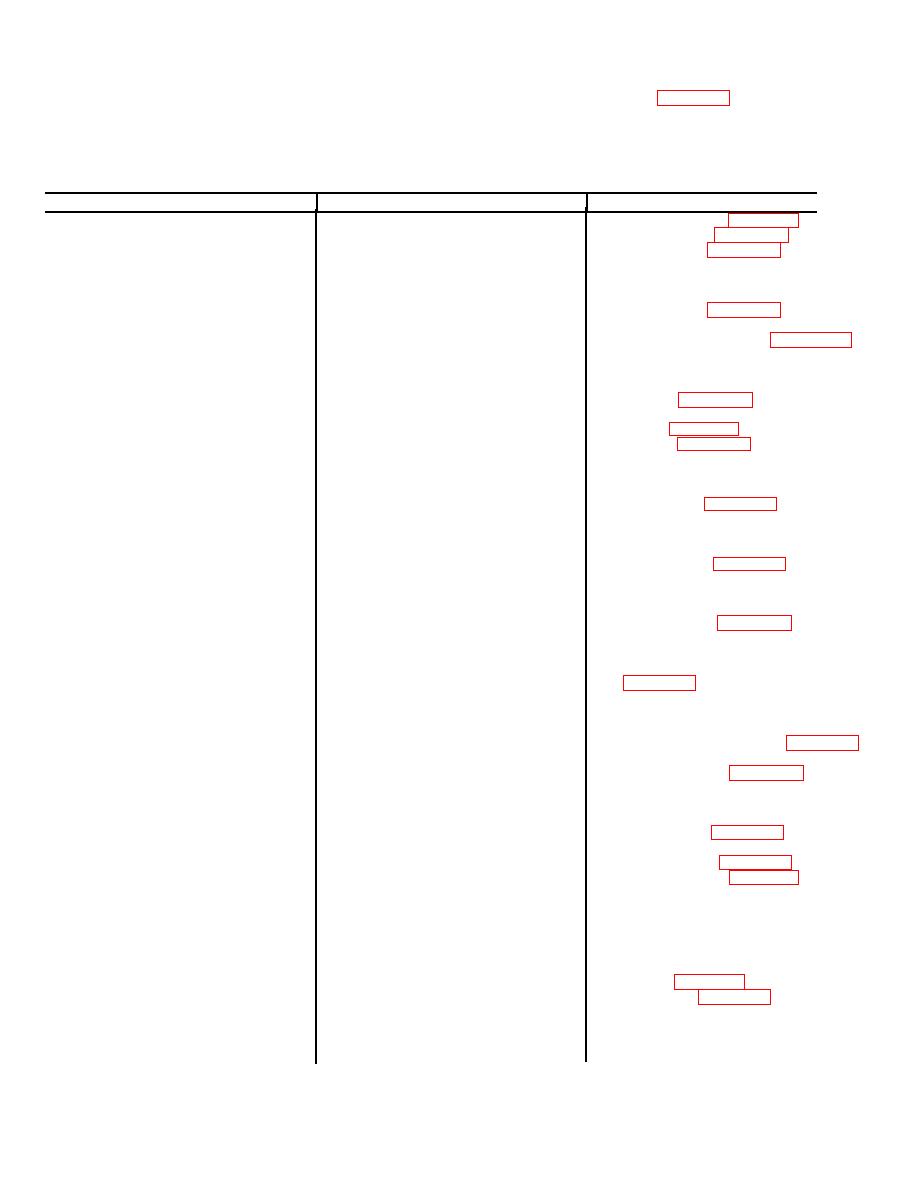

Table 4-2. Troubleshooting

Malfunction

Probable cause

Corrective Action

1. Brake pedal goes to floorboard or a.

a.

No brake fluid.

Add brake fluid (para 4-32).

b.

b.

is spongy.

Air in brake system.

Bleed system (para 4-35).

c.

c.

Brake line broken.

Replace line (para 4-34).

d.

d.

Other causes.

Refer other causes to direct and

general support maintenance

personnel.

a. Brake line kinked or clogged.

a.

2. Brakes are dragging (both or one

Replace line (para 4-34).

side only).

b. Wheel cylinder contaminated.

b. Replace wheel cylinder (para 4-33).

c. Refer other causes to direct and

c-. Other causes.

general support maintenance

personnel.

a. Brake lining worn or oily.

a. Replace (para 4-31).

3. Truck pulls to one side when

braking.

b. Brake shoes out of adjustment.

b. Adjust (para 4-31)

c. Brake line kinked or clogged.

c. Replace (para 4-34).

d. Other causes.

d. Refer other causes to direct and

general support maintenance

personnel.

4. Seat brake does not hold.

a. Not enough cable take-up.

a. Adjust yoke (para 4-30).

b. Other causes.

b. Refer other causes to direct and

general support maintenance

personnel.

a. Emergency switch not in reset

a. Reset Switch (para 4-16).

5. Failure to drive (forward or

reverse).

position.

b. Seat switch defective.

b. Refer to direct and general support

personnel.

c. Power or control fuses blown.

c. Replace fuses (para 4-21).

d. Accelerator pedal linkage loose or

d. Refer to direct and general

broken.

support personnel.

e. Battery connector not engaged or

e. Clean and engage contacts (

contacts corroded.

f. Other causes.

f. Refer other causes to direct and

general support maintenance

personnel.

a. Dragging foot brakes.

a. Check brake adjustment (para 4-31

6. Truck will not operate at

maximum speed.

b. Battery low or defective.

b. Replace battery (para 4-25).

c. Other causes.

c. Refer other causes to direct and

general support maintenance

personnel.

a. Emergency switch not in reset

a. Reset switch (para 4-16).

Failure to lift and/or tilt.

position.

b. 'Power or control fuses blown.

b. Replace fuses (para 4-21).

c. Not enough oil in hydraulic oil

c. Fill oil reservoir (para 4-48).

reservoir.

d. Other causes.

d. Refer other causes to direct and

general support maintenance

personnel.

8. Truck does not steer within the

Refer to direct and general support

within minimum turning radius.

maintenance personnel.

a. Low oil level.

a. Add oil (para 4-27).

9. Drive-axle noise on drive.

b. Oil too old or wrong type.

b. Change oil (para 4-27).

c. Other causes.

c. Refer other causes to direct and

general support maintenance

personnel.

4-5

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |