|

|||

|

|

|||

|

Page Title:

CHAPTER 3 OPERATOR/CREW MAINTENANCE INSTRUCTIONS |

|

||

| ||||||||||

|

|

CHAPTER 3

OPERATOR/CREW MAINTENANCE INSTRUCTIONS

Section I. BASIC ISSUE ITEMS

authorized for the forklift truck are listed in appendix C.

3-1. Basic Issue Tools and Equipment

Tools, equipment, and repair parts issued with or

Section II. LUBRICATION INSTRUCTIONS

an approved nonflammable cleaning solvent (Federal

3-2. Detailed Lubrication Information

Specification P-D-680) and dry thoroughly.

Clean

a. Lubrication. For current lubrication order,

lubrication points and areas around hydraulic reservoir

refer to Army Lubrication Order LO 10-3930-6250-12.

breather cap and filler before lubricating.

b.

Care of Lubricants and Lubrication

(2) Grease fittings. Wipe grease fittings

Equipment. Keep all lubricants in closed containers and

with a clean, dry cloth before lubrication. Remove old or

store in a clean dry area away from heat. Do not allow

hardened lubricant with an approved cleaning solvent.

dirt, dust, water, or foreign matters to come into contact

Remove all excess lubricant after lubricating.

with the lubricants at any time. Keep all lubrication

equipment clean and ready for use.

c. Cleaning.

by wiping it regularly with a cloth dampened slightly with

Section III. PREVENTIVE MAINTENANCE CHECKS AND SERVICES

damage the equipment or cause injury to the operator if

3-3. General

operation were continued.

Defects discovered during operation of the forklift truck

3-4. Preventive Maintenance Checks and Services

shall be noted for future correction, to be made as soon

as operation has ceased. Stop operation immediately if

Periodic preventive maintenance checks and services

a deficiency is noted during operation which would

are listed in table 3-1.

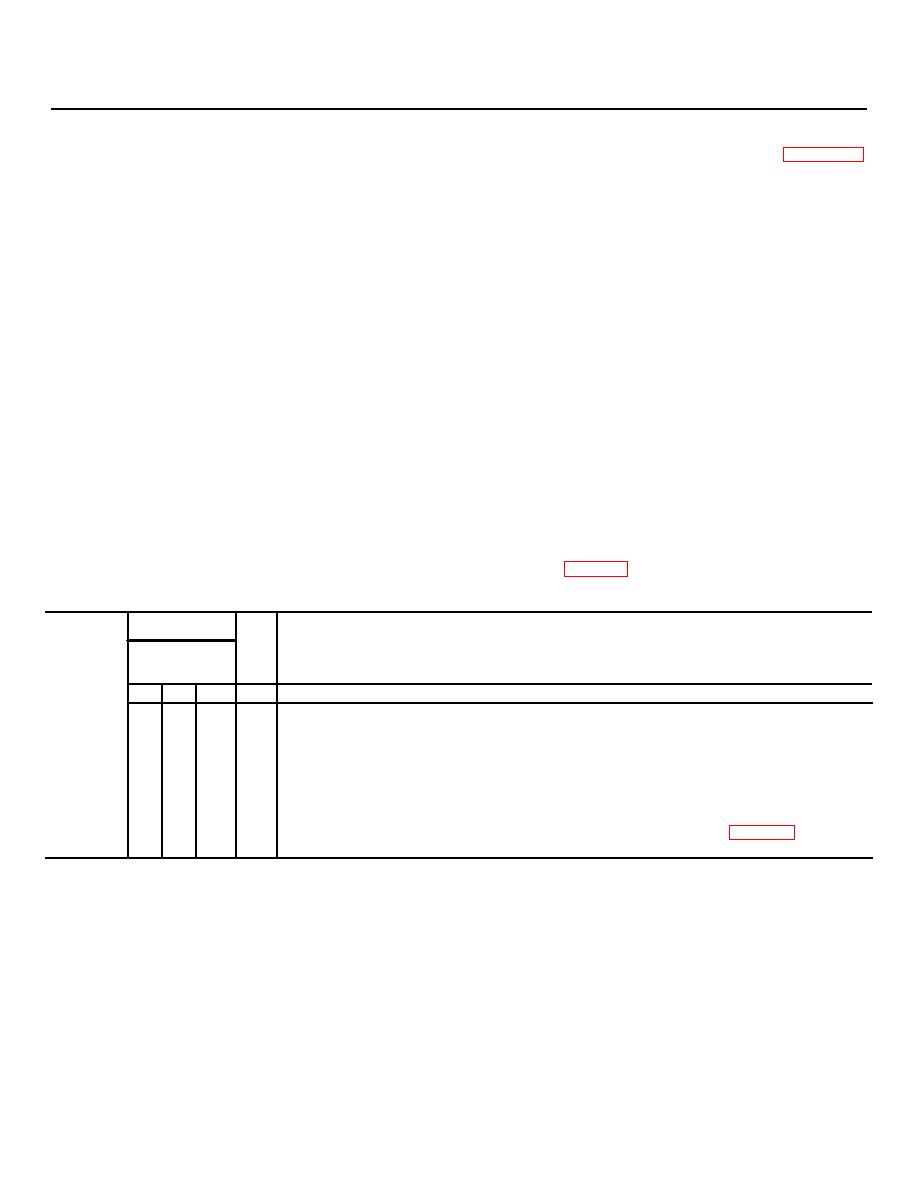

Table 3-1. Preventive Maintenance Checks and Services

Operator

B-Before operation

A-After operation

Item

Daily

W

D-During operation

W-Weekly

Number

B

D

A

Item to be inspected

Procedure

Reference

1

X

Tires

Check for wear and cuts.

Refer to direct

Remove foreign material.

support personnel

for replacement

2

X

Lift and Tilt Cylinders.

Check for leaks.

Refer maintenance

to direct and

general support

personnel.

3

X

Master Cylinder

Check fluid level. Add

fluid if needed.

3-1

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |