|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

(7) Bearing service.

(a) Inspect the drive end bearing for ex-

cessive lash between the inner and outer races,

scoring. and excessive wear. Replace if necessary.

(b) If the felt seal is worn or hardened, it

should also be replaced.

(c) Check the grease supply in the slip ring

end frame bearing. If it is exhausted, the bearing

should be replaced.

ME 3930-624-34/5-4

ME 3930-624-34/5-5

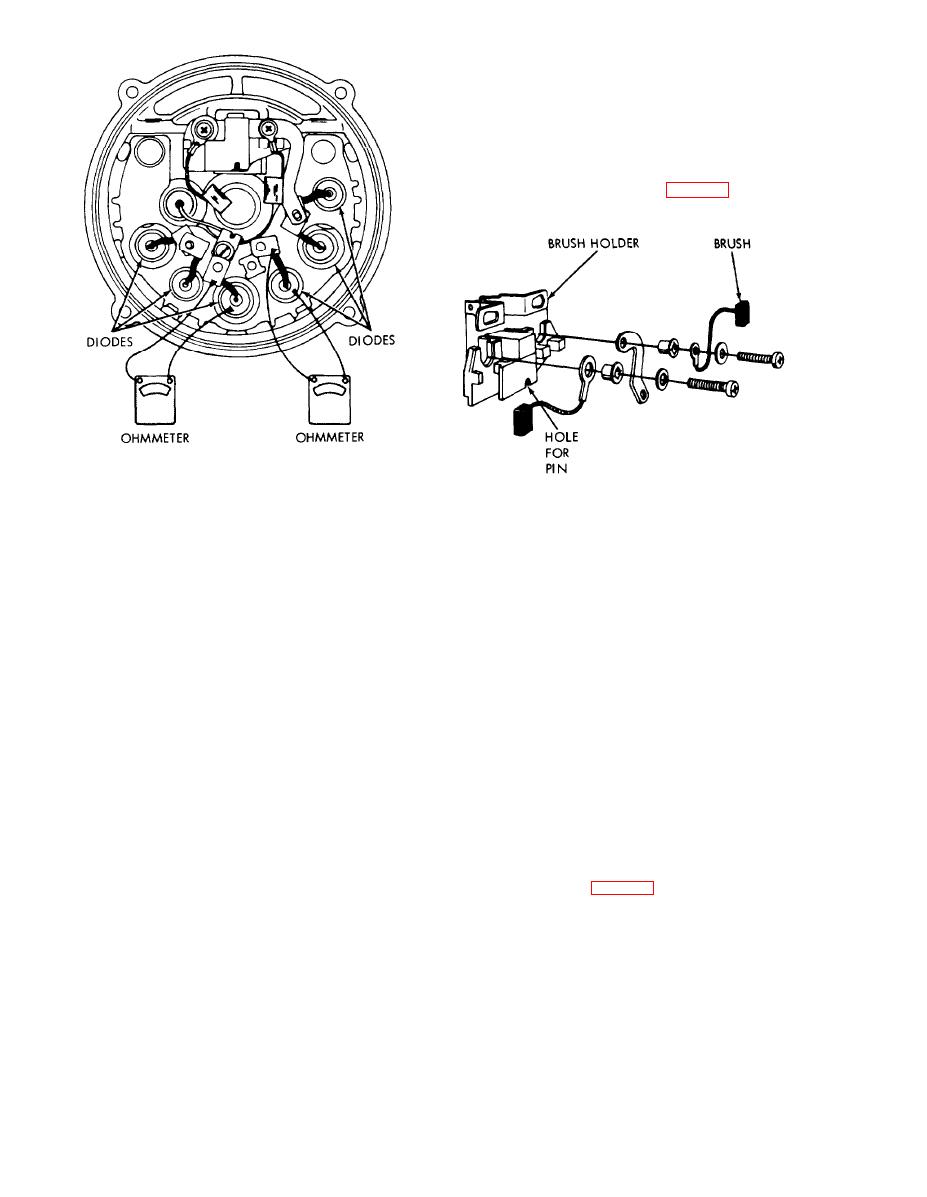

Figure 5-4. Checking the diodes.

Figure 5-5. Alternator brush replacement.

(5) Diode replacement.

(a) Remove the two brush holder screws.

(a) Support the end frame or heat sink in a

(b) Remove the brush holder assembly from

suitable toot.

the end frame. Remove brushes and springs. The

(b) Remove the old diode with an arbor

length of a new brush is in. and should be

press.

replaced when they reach a length of 3/8 in. Check

(c) Press in the new diode. Apply the

the spring tension of the brush springs. It should be

pressure to the outer edge of the diode.

between 8 and 12 ozs.

Caution: Do not try to hammer the new

(c) Install new springs and brushes in the

diodes into the heat sink or end frame. The

brush holder.

shock will damage them.

(d) Insert a piece of straight wire or a pin

(6) Slip ring service.

into the holes at the bottom of the brush holder to

retain the brushes in their proper position.

Note. To clean dirty slip rings, use a 400 grain or finer

(e) Install the brush holder assembly onto

polishing cloth.

the end frame, noting carefully the proper align-

(a) Secure the rotor in a lathe.

ment of parts.

(b) Hold polishing cloth against the slip

Note. Be sure to allow the straight wire to protrude

rings white the rotor is rotating until they are clean.

Caution: The rotor must be rotated so

through the hole in the end frame.

that the slip rings will be cleaned evenly.

Trying to clean the slip rings by hand without

(1) Install the stator (15) in the drive end

spinning the rotor will cause flat spots on the

frame (14).

slip rings, resulting in brush noise.

(2) Install the pulley assembly on the rotor and

(c) If the slip rings are rough or out of

tighten the shaft nut to a torque of 50-60 ft. tbs.

round, they must be trued to a maximum indicator

(3) Before installing the slip ring end frame

reading of 0.002 in.

assembly (14) to the rotor (8), remove the tape

(d) Polish the trued slip rings with 400 grain

from the bearing and shaft.

or finer polishing cloth and blow away ail dust with

(4) Install the remaining parts in the reverse

compressed air.

order of disassembly.

5-4

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |