|

|||

|

|

|||

|

Page Title:

Section VI. REPAIR OF STEERING SYSTEM |

|

||

| ||||||||||

|

|

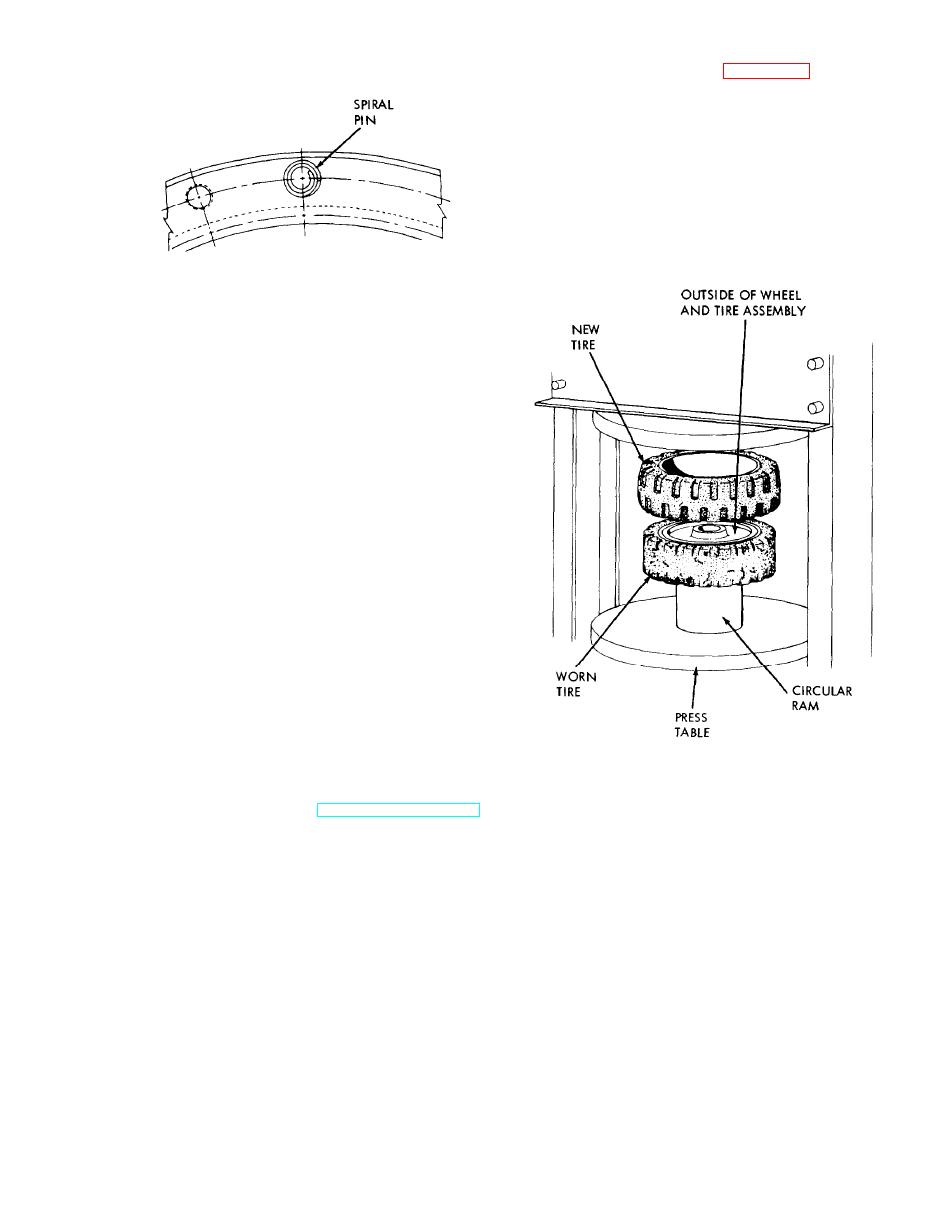

a circular ram having a smaller outside diameter

than the tire inside diameter and place in a 100 ton

or larger hydraulic press. See figure 4-25. Position

the new tire on top of the old tire. Run the press

slowly for the first few inches of travel. If the tire

begins to cock, stop and realign it. A sharp tap with

a soft headed mallet will usually do this. Continue

pressing until the old tire is off and the new tire is

correctly positioned on the wheel. Make sure the

rim of the new tire is pressed onto the wheel to the

same location as the original.

ME 3930-324-34/4-24

Figure 4-24. Spiral pin installation.

(e) Position the bull gear, bottom side

down, in the drive wheel. Aline the spiral pins with

the holes in the drive wheel and tap the bull gear

evenly to start it into the drive wheel.

(f) Install the capscrews which were

originally removed and alternately tighten the

capscrews and tap the bull gear until the gear is

seated. Try to insert a 0.003 inch feeler gage

between the gear and the shoulder. When the gear

is properly seated, the gage will not enter at any

point. Tighten the capscrews to a torque of 28 to 32

ft lbs.

(3) Brake drum.

(a) When resurfacing the brake drums,

follow the resurfacing equipment manufacturer's

instructions. Always resurface both drums of the

truck to an equal diameter.

(b) Finish grind or hone the drums to

remove cutting tool marks. Otherwise, linings will

wear rapidly. If a brake drum surface requires

machining to a diameter greater than 0.030 inch

beyond original diameter, t h e w h e e l m u s t b e

discarded. Thin drums may break under strain.

Original brake drum surface diameter is 13.135 to

13.143 inches.

ME 3930-624-34/4-25

d. Reassembly. Assemble the wheel in the

Figure 4-25. Tire replacement.

reverse order of disassembly.

e. Installation. Refer to TM 10-3930-624-12.

4-16. Tire Replacement

Place the old wheel, with the chamfered side up, on

Section VI. REPAIR OF STEERING SYSTEM

4-17. General

hydraulic, with no mechanical connection between

The steering system consists of the steering wheel,

the column assembly and the cylinder. The base of

column and valve assembly, the power steering

the cylinder is anchored to the frame. The pivot

cylinder and the steer axle assembly. Oil for the

arm is connected to the steer wheel spindles by two

power steering system is supplied by the hydraulic

tie rods.

pump. w h i c h a l s o s e r v e s t h e t r u c k h y d r a u l i c

system. The power steering system is fully

4-27

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |