|

|||

|

|

|||

|

Page Title:

Cleaning, Inspection and Repair. |

|

||

| ||||||||||

|

|

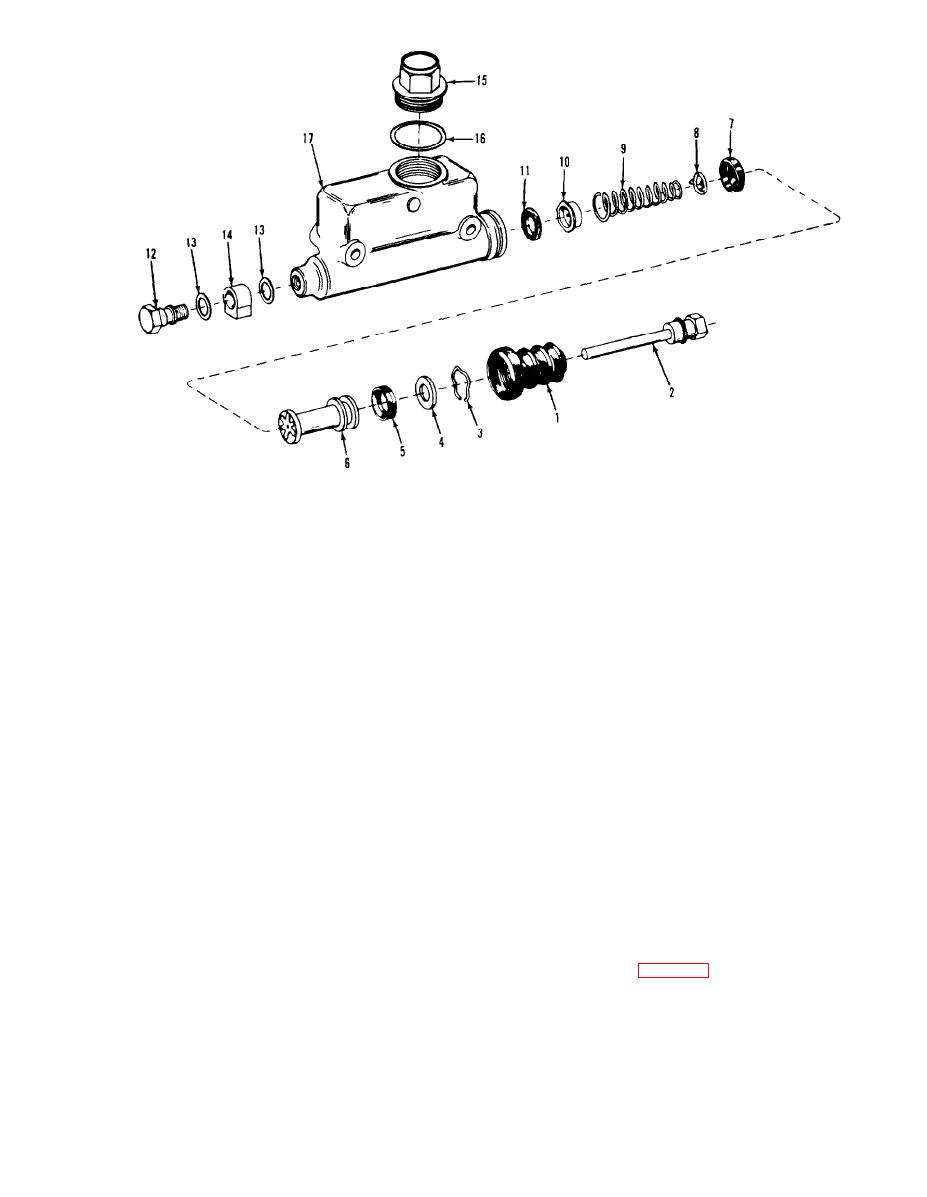

ME 3930-624-34/4-19

1. Boot

10. Valve

2. Push Rod

11. Seal

3. Lock ring

12. Bolt

4. Plate

13. Copper gasket

5. Seal

14. Fitting

6. Piston

15. Filler cap

7. Cup

16. Gasket

17. Body

8. Retainer

9. Spring

Figure 4-19. Master cylinder, exploded view.

c. Cleaning, Inspection and Repair.

equipment manufacturer's instructions. Remove

(1) Use a lint-free cloth and clean the parts in

material in single passes. After each pass, remove

denatured alcohol or clean brake fluid.

the hone and inspect the bore to see if all blemishes

Caution: Any solvents other than alcohol

have been removed. Remove only enough material

or brake fluid will deteriorate rubber parts,

to eliminate blemishes. If the cylinder bore is honed

causing them to become soft, tacky and

beyond the allowable tolerance. replace the master

swollen.

cylinder. Original cylinder bore is 1.000 to 1.007

inches.

Cylinder castings may be cleaned with the usual

(4) After honing, remove the cylinder from

cleaning methods. but must be finish cleaned with

the vise and clean the cylinder thoroughly. Check to

alcohol or brake fluid to remove all traces of other

be certain the ports are open and free of burrs

solvents. Parts must be kept clean for reassembly.

which might cause damage to moving parts.

(2) Inspect the cylinder bore. Deep blemishes

(5) Replace the parts which are contained in a

will require honing to resurface the cylinder wall.

repair kit. Replace all other parts which are worn.

Pressure marks and discoloration may he polished

damaged, or corroded.

out with crocus cloth. (Do not use sandpaper or

emery cloth.) Make certain all the ports are open.

(1) Lubricate the ports and the cylinder bore

The intake and bypass ports (inside the reservoir)

with clean hydraulic brake fluid.

may be probed with a soft iron wire.

(2) Install the valve (10), seal (11), spring (9)

(3) If honing is necessary, coat the cylinder

and retainer (8) in the bore. The large end of the

bore with hydraulic brake fluid. Follow the honing

4-21

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |