|

|||

|

|

|||

|

Page Title:

Perform the following measurements and inspections on the connecting rod. |

|

||

| ||||||||||

|

|

and installation tool. Take care not to spread the

rings more than necessary. Stagger the ring gaps

evenly around the piston so that no two are in line.

(2) Use the following procedure to install the

oil control rings (11).

(a) Place the stainless steel expander spacer

of the three piece ring in the nil groove with the

ends butted.

(b) Install the steel segment on top of the

expander spacer with the gap of the segment ap-

proximately 90 beyond the gap of the stainless

steel expander. Make certain the expander remains

butted.

(c) Install the second segment on the

bottom side of the expander spacer. Position the

segment gap approximately 90 from the expander

spacer gap in the opposite direction from which the

top segment has been positioned.

(d) Recheck the installation. The nil control

ring should be free to move in the groove. A slight

drag will be noticed due to the side sealing action of

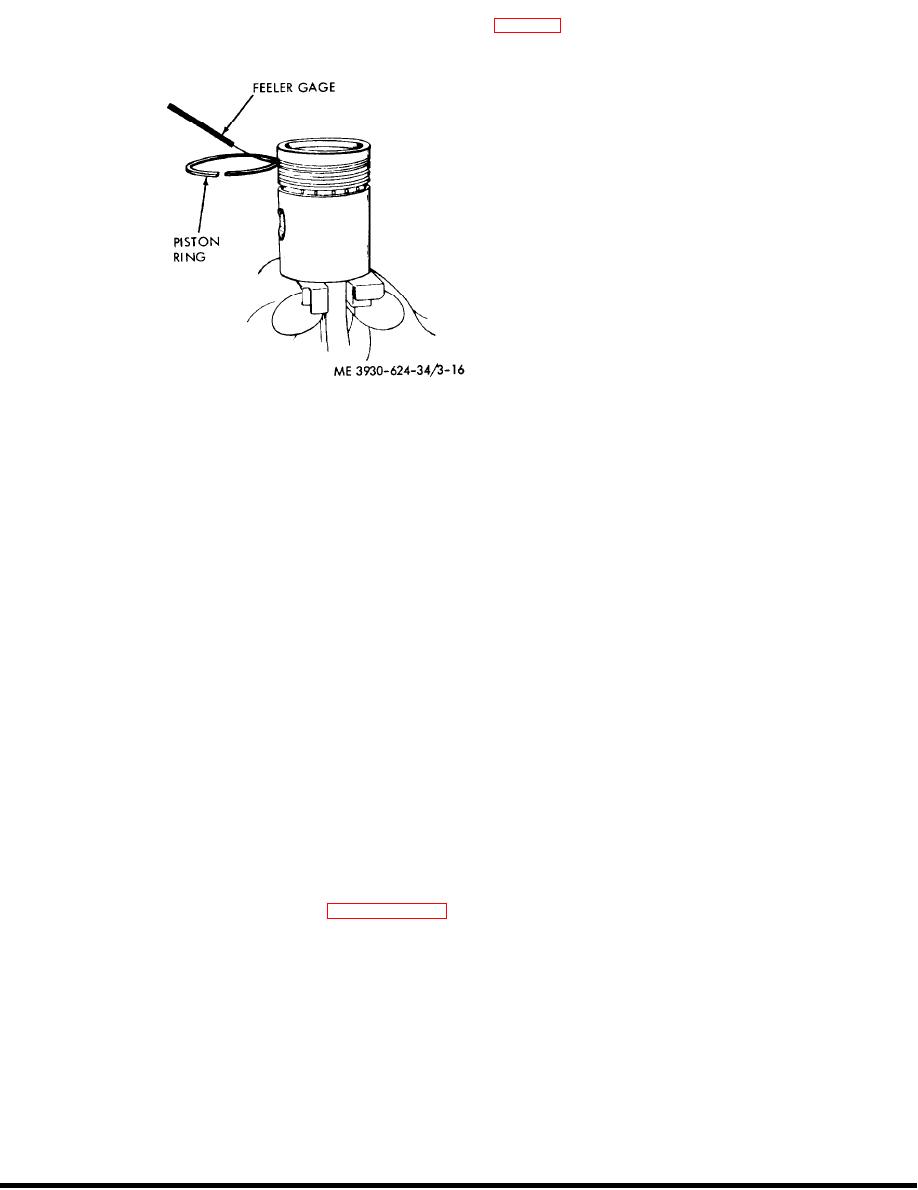

3-16. Checking ring-to-groove clearance.

the steel segments. Make sure the expander spacer

Figure

remains butted.

(4) Perform the following measurements and

(3) If the connecting rod bushing (9) is worn,

inspections on the connecting rod.

the old bushing may be pressed nut and a new

(a) Measure the outside diameter of the

bushing pressed in. Refer to the inspection

piston pin to determine the wear. The specified

procedure above to determine if the bushings are to

diameter of a new piston pin is 0.8591-0.8593 inch.

be replaced.

(b) The specified inside diameter of the

(4) If there is no wear between the piston (7)

connecting rod bushing is 0 . 8 5 9 3 - 0 . 8 5 9 6 i n c h .

a n d t h e p i n ( 6 ) , b u t wear exists between the

pin to bushing clearance is 0.0000-0.0005 inch.

bushing (9) and the pin, install a new bushing and

Clearance up to 0.0020 inch is permissible. If the

ream to fit a standard size pin.

clearance is close to or beyond this limit, replace the

(5) Use the following procedure to assemble

connecting rod bushing.

the connnecting rod (8) and piston.

(c) Inspect the connecting rod bearing

(a) Install one of the piston pin retaining

shells for scoring, chipping, corrosion, cracking, or

rings (5) in one end of the hole in the piston.

signs of over-heating. Discard the bearing shells if

(b) Immerse the piston in boiling water for

any of these conditions are apparent. The back of

approximately five minutes. Then insert the upper

the bearing shells should be inspected for bright

end of the connecting rod into the piston and insert

spots and discarded if any are found. This con-

the piston pin (6).

dition indicates they have been moving in their

(c) Install the other piston pin retaining

supports.

ring (5) at the opposite end of the piston pin.

(d) Inspect the bearing shells for wear. The

(6) When installing the pistons and con-

specified inside diameter of the bearing shells when

necting rods, b e s u r e t o p l a c e t h e m i n t h e i r

installed is 2.1239-2.1254 inches. This provides a

respective cylinders. The number on the bearing

running clearance of 0.0015-0.0040 inch. New

cap (3) should be opposite the camshaft side of the

bearing shells must be installed when this clearance

engine.

exceeds 0.000 inch.

(7) Place a ring compressor over the piston

rings. Make certain that the rings are wholly in

vvear and clearance. Refer to paragraph 3-17.

their grooves before tightening the compressor.

(5) If wear on the rod bushings or bearings

Tighten the compressor gradually. Pause to move

indicates that the rod is bent, replace the rod.

the compressor sideways to be sure the rings are

d. Reassembly and Installation.

free. Compress the rings as much as possible.

(1) If the rings have been removed from the

(8) Place the piston and connecting rod in its

piston. new rings must be installed. Refer to the

respective cylinder sleeve. The lower end of the

ring inspection procedure above to ensure that the

connecting rod should be aligned with the

rings meet with specifications. Install the rings (10.

3-19

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |