|

|||

|

|

|||

|

Page Title:

Use the following procedure to align the torque converter. |

|

||

| ||||||||||

|

|

b. Installation.

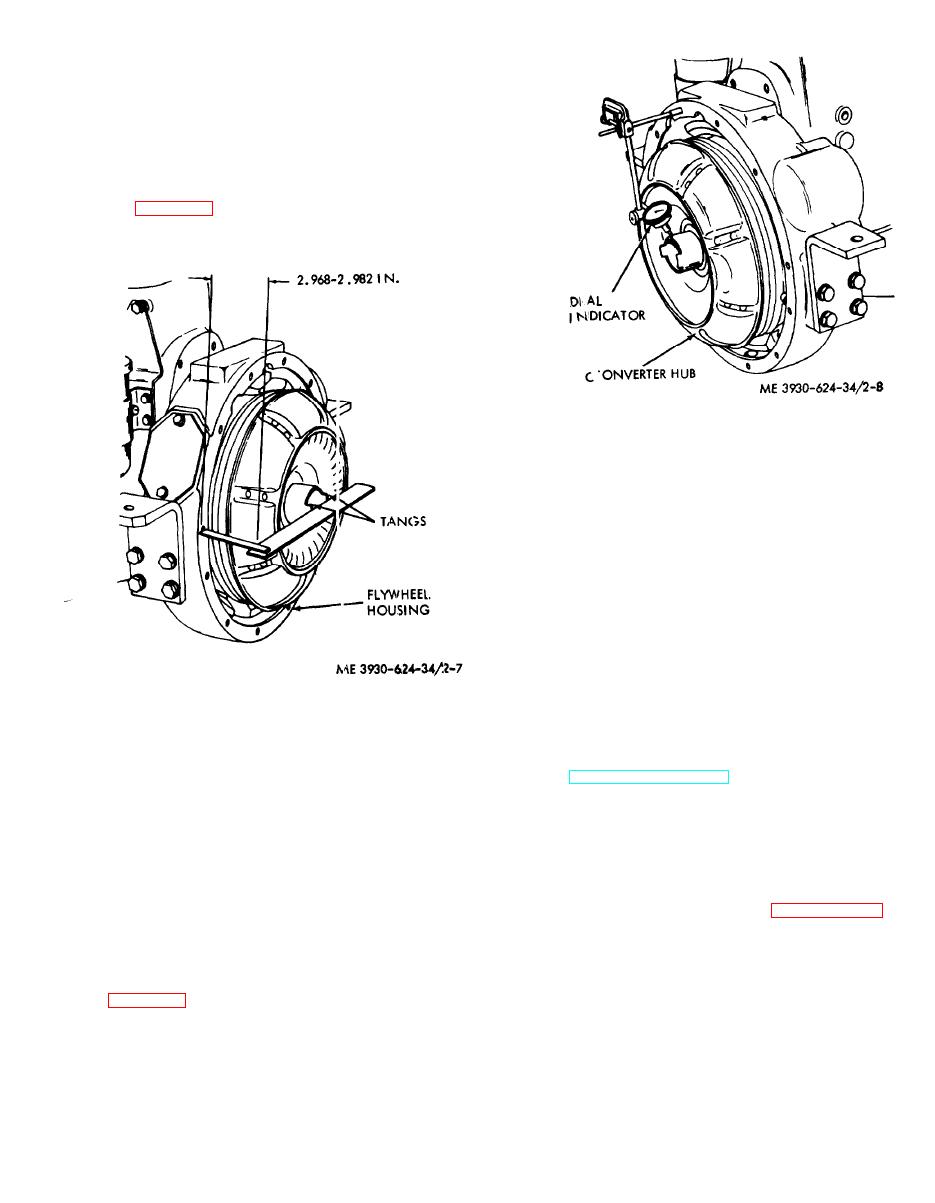

(1) When installing the converter, use the

following procedure to ensure that the tangs of the

converter extend the proper depth into the pump.

(a) Without the shims on the pilot, install

the converter on the flywheel and tighten the

capscrews.

(b) Place a scale or rule across the tangs of

the converter and another scale from the face of the

flywheel housing to the scale across the tangs. Refer

to figure 2-7.

Figure 2-8. Checking converter alinement.

(b) Rotate the converter and note the dial

indicator reading. The hub runout should not

exceed 0.005 inch or 0.010 inch total indicator

readout.

(c) Rend the converter plate to adjust to the

correct reading. Do not use shims between the plate

and the flywheel.

(d) After correct alignment is obtained,

recheck the tang depth as described in (1), above.

(3) Use the for lowing procedure for installing

truck.

(a) Mount the converter to the flywheel by

installing the capscrew s and lockwashers through

the inspection plate in the flywheel bell housing.

(b) After the converter has been securely

installed, rotate the converter hub until the filler

Figure 2-7. Checking tang depth

hole appears an d add one quart of oil. Refer to the

(c) Record the measurement from the face

current LO 10-3930-624-12 for the proper oil-

of the tangs to the face of the housing.

(c) After the assembly has been installed in

(d) If the measurement is less than 2.968

the truck add 10 quarts of oil to the transmission.

inches. remove the converter and add shims at the

(d) InstaII the floor plate, toe plate, seat and

converter pilot to obtain the specified dimension.

support, battery and battery case and corner post.

(e) If the measurement is more than 2.982

2-10. Front Axle Assembly (Drive)

inches. i n s e r t a g a s k e t b e t w e e n t h e c o n v e r t e r

a. Removal.

housing and flywheel housing. Make the gasket the

(1) Remove the mast. Refer to paragraph 6-2.

thickness required to obtain the specified

(2) Disconnect the main hydraulic brake line

dimension.

at the junction block located on the differential

(2) Use the following procedure to align the

housing. Disconnect the hydraulic lines or any

torque converter.

other lines which are attached to the front axle

(a) Mount the dial indicator as shown in

housing. Cap or plug openings.

2-11

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |