|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

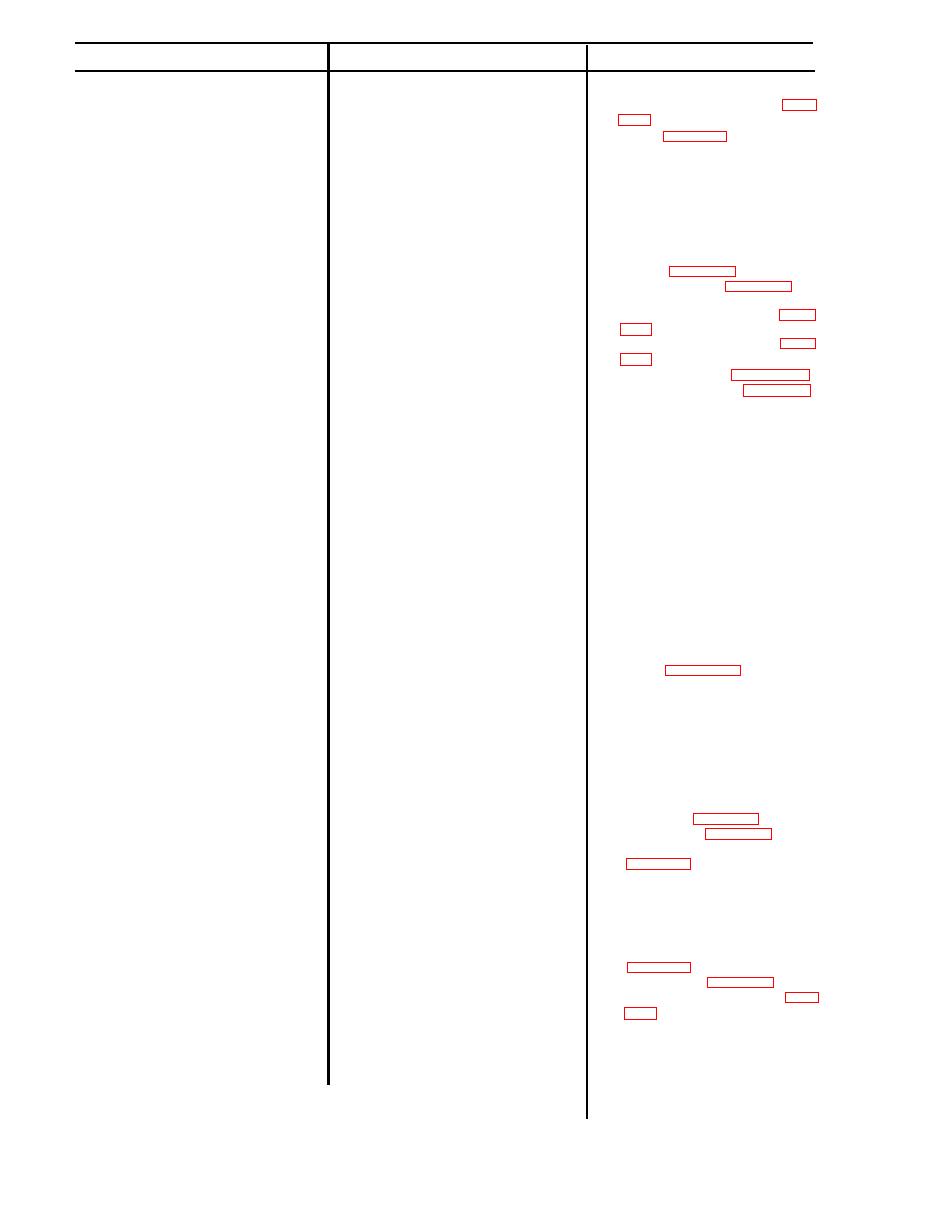

Corrective Action

Probable Cause

Malfunction

the cylinder head. Free the values

by cleaning the valve stems.

Replace valves if burned (para

d.

Replace (para 3-12).

d. W arped valves.

e.

Remove valve cover, and with

e. Stuck valve.

screwdriver, free the sticking

valve. Valve stem and guide will

have to be cleaned to restore

proper clearance. If condition

continues, valves need regrind-

ing.

a.

Remove cylinder head. Clean out

4. Engine knocks.

carbon (para 3-12).

(pinging knock in cylinder).

b.

Replace bearings (para 3-16).

(Sharp knock, low oil pressure.1

c. Loose m a i n b e a r i n g s . ( H e a v y

knock-low oil pressure.)

d. Loose piston pins. (Sharp double

knock.)

e. Piston and cylinder wear.

pistons. and rings lpara 3-16).

a.

Use

solvent

solution

and

a. Scale in water jacket.

5. Engine overheats.

thoroughly flush the cooling

system.

Caution: Never mix

coolant compounds or

inhibitors with any

cleaning, neutralizing, or

flushing compounds.

b. Remove by thoroughIy flushing

b. Particles of rubber hose or other

out radiator and cooling system.

foreign substances inside the

cooling system.

c. Replace hose.

c. Intake hose at pump collapses.

d. Tighten bolts.

d. Loose timing coupling bolts.

e. Remove by use of air hose or

e. Radiator core clogged.

brush.

f. Leaky radiator.

quick-stop leak solders. because

these tend to clog the circulation.

Lead scolder must be used.

a. Repair leaks by tightening the

a. Low oil pressure. due to external

6. Loss of power.

connection replacing the line.

oil leaks. thin oil, or sticking of oil

Drain and fill with fresh oil.

pressure relief valve.

Remove oil pressure relief valve

and clean. Do not switch spring.

b. Tighten connections.

b.

Air leak at fuel line.

c.

Leaky valves.

d.

W orn piston rings.

e. Replace cylinder head gasket

e.

Blown cylinder head gasket.

f. Clean air cleaner and tubing.

f.

Air cleaner obstructions.

g. Remove obstruction.

g.

obstruction in exhaust line.

h. Adjust.

h.

Choke valve out of adjustment.

a. Check battery. distributor. cables

a.

W eak spark.

7. Explosion in exhaust

ignition coil.

b. Replace weak or broken spring

8.

Engine

runs

irregularly

(sput-

b. Leaky valves.

ters).

c. Tighten capscrews or replace

c. Leaky intake manifold.

gaskets.

2-2

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |