|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

(2) Connect a voltmeter across the terminals

of the battery, and note the reading. Pull the high

tension cable from the ignition coil, crank the engine

with the starter, and note the reading on the voltmeter.

If the difference between the two is more than 4 volts or

the second reading is less than 8 volts, replace the

battery.

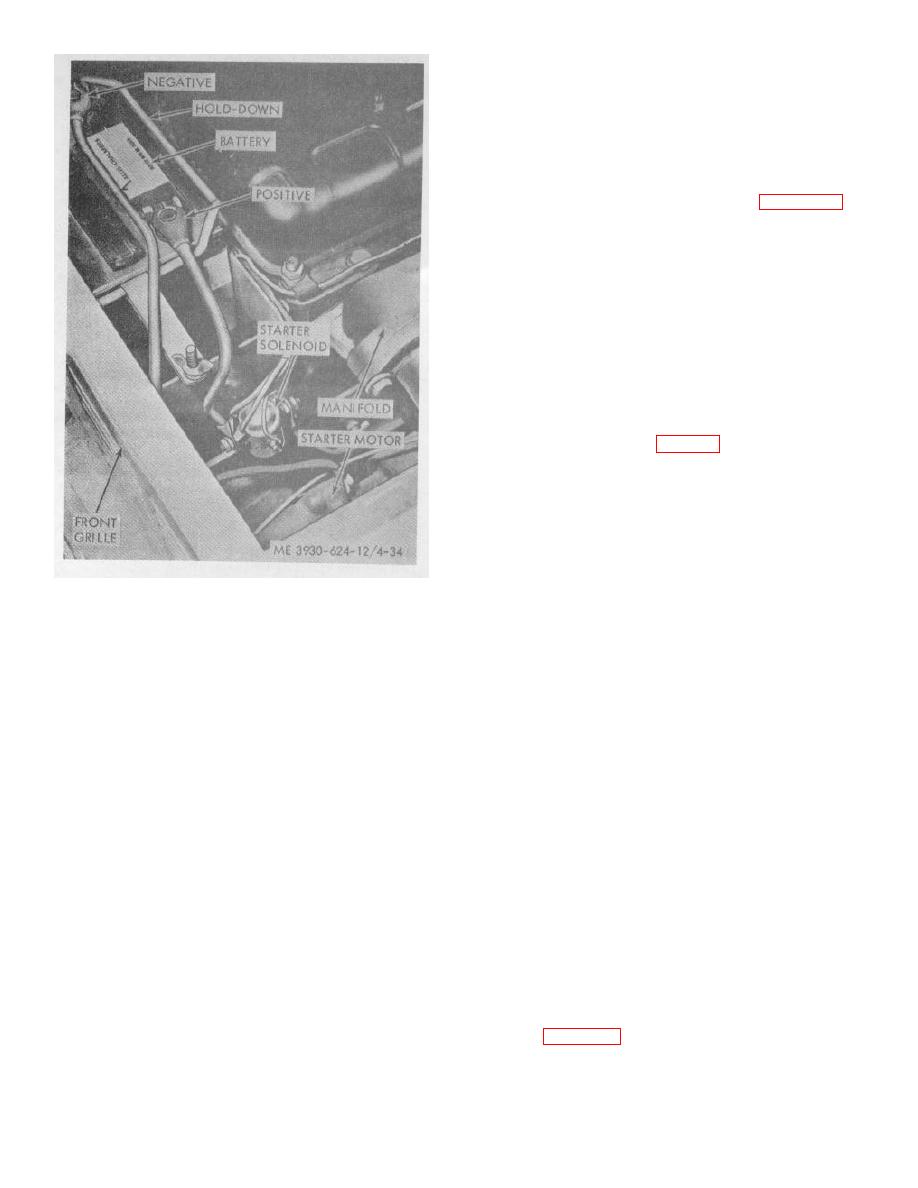

c. Battery Removal.

(1)

Loosen the nuts (fig.

that secure the battery cables to the battery posts;

remove the cables.

(2) Remove the two wing nuts from hold-

down studs and remove battery hold-down. Remove the

battery.

d. Cleaning and Inspection.

(1) Clean the battery tray and hold-down by

flushing with a solution of baking soda and water. Flush

parts until bubbling stops when new solution is applied.

(2) Inspect the battery for loose posts, cracks,

evidence of leaks, or other damage.

e. Installation. Install battery by reversing the

removal procedure.

(1) Loosen the nuts that secure the cables to

the battery posts; disconnect the cables. Remove the

cable clamp that secures the cables to the truck frame.

(2) Remove the starting motor mounting bolt

and lockwasher that secure the negative cable to the

frame of the truck; remove the cable.

(3) Remove the nut and washer that secure

the positive cable to the starter solenoid; remove the

cable.

Figure 4-34. Battery location.

g. Cleaning and Inspection.

(1) Clean the cables with a rag dampened

(2) Remove dirt and grease accumulated on

with a cleaning solvent. Clean cable clamps and lugs

the battery with a clean cloth.

with a wire brush.

(3) Pour a solution of baking soda and water

(2) Inspect the cables for cracked insulation,

on the battery to neutralize any acid present. Continue

breaks, or other damage.

to pour until the solution no longer bubbles when it

(3) Inspect cable clamps and lugs for

contacts the battery.

corrosion, distortion, poor connections to cables, or

Caution: Remove the negative cable first.

other damage.

When installing cables install the negative cable

(4) Replace the cables if defective.

last.

h. Cable Installation. Install cables by using the

(4) Loosen the nuts that secure the battery

direct reversal of removal procedure.

cables to the battery posts; remove the cables. Clean

all corrosion from the cable clamps and posts with a

4-40. Instrument Panel

wire brush. Reattach the cables; tighten the nuts.

a. Removal and Disassembly.

(5) Lightly coat the battery posts and cable

Warning: Disconnect the negative battery

clamps with. petroleum jelly.

cable from the battery before disconnecting

b. Battery Testing.

electrical leads from the controls and instruments

(1) Test the state of the electrolyte using a

on the instrument panel.

hydrometer. The specific gravity of the electrolyte at

(1) From beneath the right hand side of the

75 F should be 1.225 minimum for normal temperature

instrument panel, disconnect the male line connector.

operation, or 1.265 minimum for cold temperature

(2) At the front of the panel, insert a

operation. For constant operation in above freezing

screwdriver under the edge of the instrument panel at

temperatures, electrolyte strength may be reduced to

the lock pins, and pry the panel away from the pins.

1.225 by diluting with distilled water. If the battery is not

Refer to figure 4-35.

fully charged, charge it.

4-34

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |