|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 10-3930-623-34

7-57. HYDRAULIC PUMP TEST. After installation, test

7-54. HYDRAULIC SYSTEM COMPONENTS.

hydraulic pump by raising a four thousand pound load.

Operate through several cycles to be sure all air is bled

7-55. GENERAL INSPECTION.

from the system. After operation inspect visually for

1. Examine hydraulic hoses and fittings for wear,

security of mounting and for leaks.

damage, looseness, or any form of deterioration.

Discard defective parts.

CAUTION

2. Inspect oil reservoir for leaks, damage, or

Never operate engine without full

looseness of mounting. Inspect drain cock for corrosion

hydraulic reservoir. Hydraulic pump

and damaged threads.

is connected directly to engine and

requires a full hydraulic system for

3. Examine all bolts, screws, nuts, and hose

lubrication.

clamps for crossed, stripped, or damaged threads.

Make sure bolts or screws are not bent. Discard

7-58. HOIST AND TILT CYLINDERS INSPECTION.

defective parts.

Inspect all parts of hydraulic cylinders for cracks,

fractures, wear, distortion, and other damage. Carefully

inspect welded seams of cylinder tubes for cracks and

7-56. HYDRAULIC PUMP INSPECTION.

defects. Examine cylinder head for damage. Inspect

1. Inspect end cover flange (4, figure 4-7) and

piston and inside diameter of tube for wear and out-of-

pump body (35) for cracks and damage. Inspect bearing

round. Discard defective parts.

counterbores and shaft bearing surfaces in body and

covers for excessive wear and damage. Inspect all

7-59.

HOIST AND TILT CYLINDERS

machined surfaces for scoring, wear and damage.

EXTERNAL LEAKAGE TEST.

2. Inspect gears (13 and 14) for excessive wear

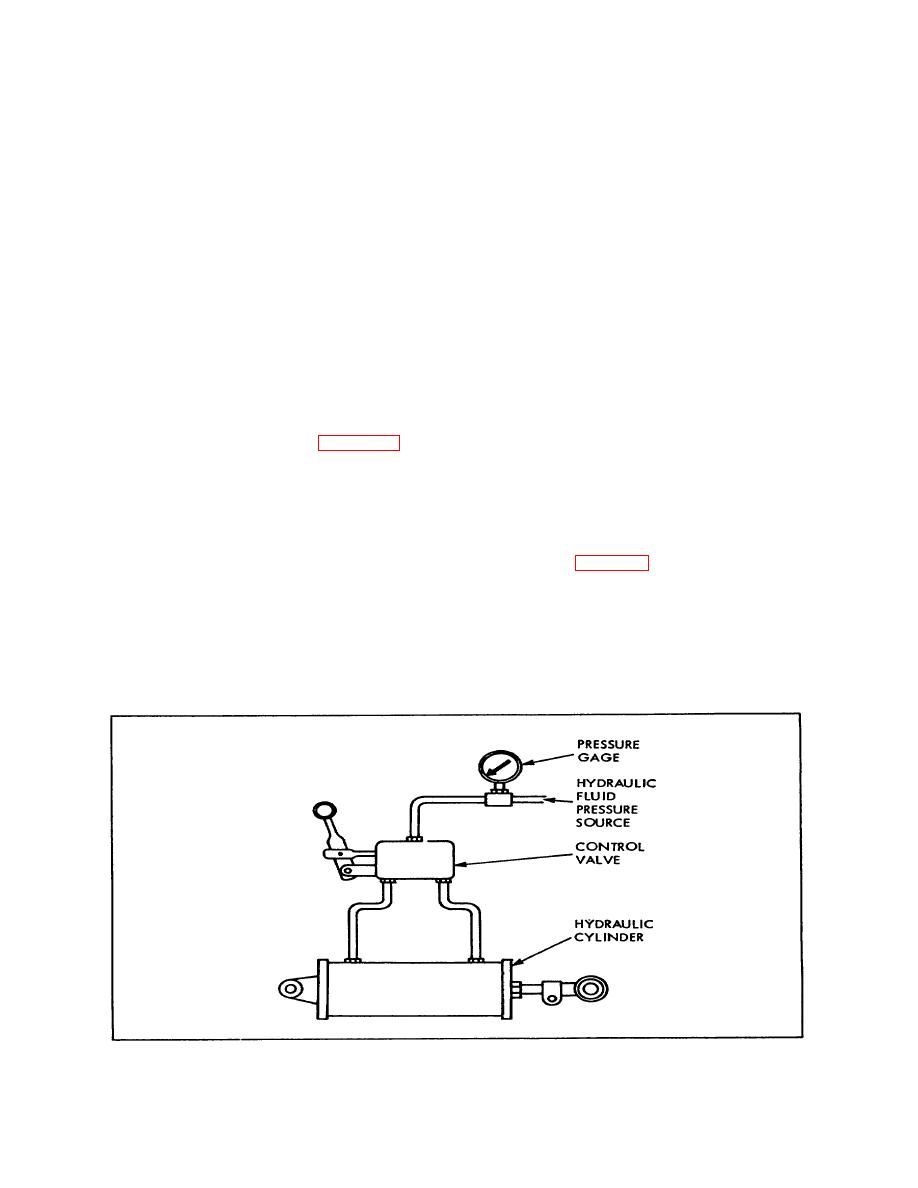

1. Connect hydraulic tilt cylinder to test

and chipped or damaged teeth. Replace gears in

arrangement (figure 7-7). Use approximately 1200 psi in

matched sets.

testing.

3. Inspect shafts for loose key, worn bearing

2. Actuate control valve to move piston to one

surfaces, and damage.

extreme end of tube. Observe exterior of cylinder

assembly for evidence of oil leakage.

4. Inspect bushings (11) for wear, scoring, and

damage.

Figure 7-7. Typical Hydraulic Tilt Cylinder Test Setup

7-16

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |