|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 10-3930-623-34

3. Lubricate packing (58) with automotive and

6-68. ADJUSTER PLUG DISASSEMBLY.

artillery grease, MIL-G-10924, and install on adjuster

1. Remove thrust bearing retainer (57, figure 4-32)

plug. Assemble large thrust bearing race (53), thrust

with a screwdriver, being careful not to score the needle

bearing (54), small thrust bearing race (55), and thrust

bearing bore, and discard.

Remove thrust bearing

bearing spacer (56) on adjuster plug. Press new bearing

spacer (56), thrust bearing (54) and thrust bearing races

retainer (57) into needle bearing bore, using thrust

(53 and 55).

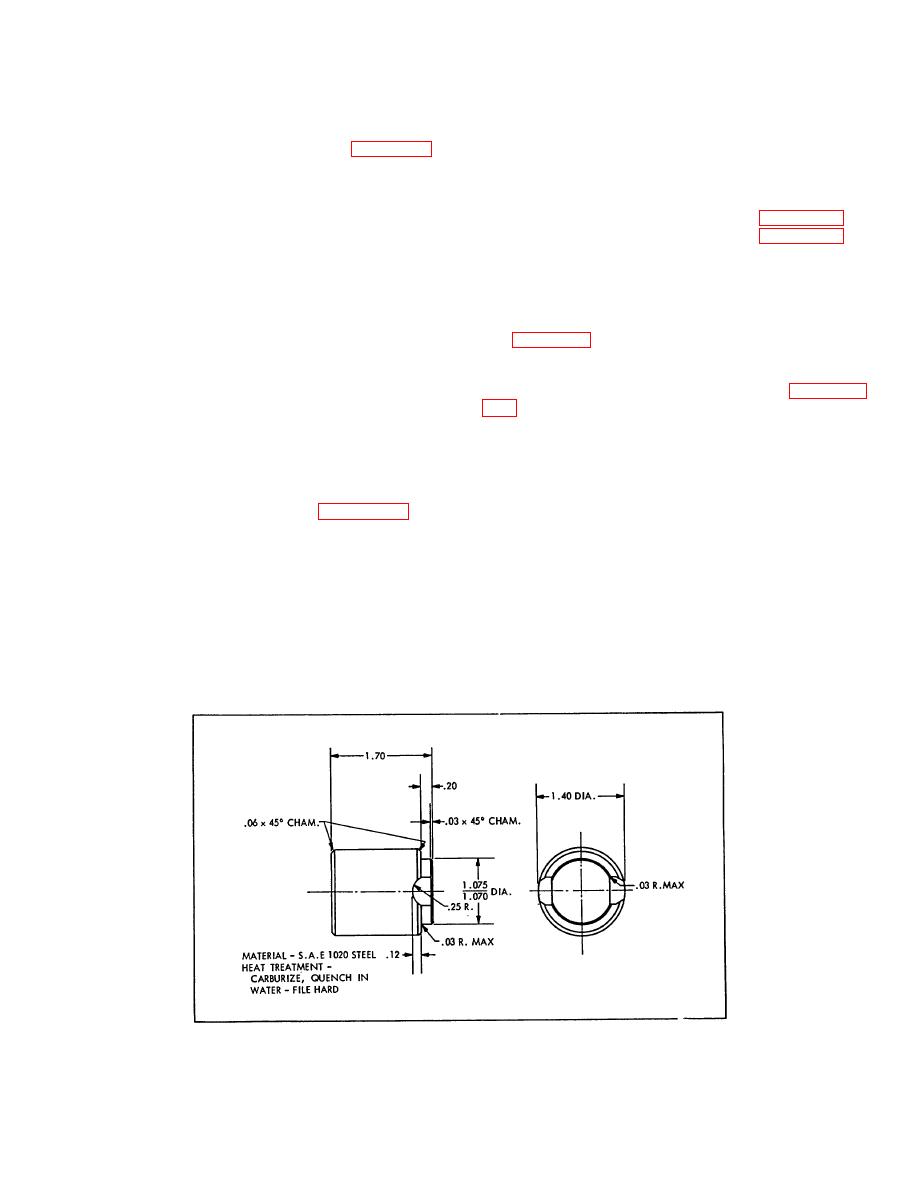

bearing retainer installer, as shown in figure 6-11. If

necessary, make installer locally, using figure 6-11 for

2. Remove adjuster plug packing (58) and discard.

guidance.

3. Remove stub shaft seal retaining ring (50), with

6-70. ADJUSTER PLUG INSTALLATION.

snap ring pliers, and remove stub shaft dust seal (47).

1. Place tool to protect seal over end of stub shaft

4. Remove stub shaft oil seal (48) by prying out

(76, figure 4-32).

with screwdriver and discard.

2. Install adjuster plug assembly in gear housing.

5. Inspect adjuster plug needle bearing (51), and if

Adjust thrust bearing preload according to paragraph

rollers are broken or pitted, remove needle bearing from

adjuster plug by pressing from thrust bearing end using

piloted driver. Discard bearing.

6-71. STEERING GEAR VALVE. The complete valve

in each steering gear is a precision unit with selective

fitted parts and is hydraulically balanced at assembly.

6-69. ADJUSTER PLUG ASSEMBLY.

Only those parts which are service items are replaceable

1. Assemble needle bearing (51, figure 4-32) by

and interchangeable.

No other valve parts are

pressing from thrust bearing end of adjuster plug (52)

individually interchangeable.

Replacement of any

against identification end of bearing. End of bearing is to

nonserviceable valve part requires that complete rotary

be flush with bottom surface of stub shaft seal (48) bore.

valve assembly be replaced. Do not disassemble the

valve unless necessary since this may result in

2. Lubricate new stub shaft seal with OE-10 engine

damaging the assembly.

If valve spool dampener

oil and install far enough to provide clearance for dust

packing requires replacement, remove valve spool only,

seal (47) and retaining ring (50). Lubricate new dust

replacing packing, and reinstall spool immediately. Do

seal with engine oil and install with rubber surface

not disassemble further. Proceed as follows:

outward. Install retaining ring (50), making certain that

the ring is properly seated.

Figure 6-11. Steering Gear Thrust Bearing Retainer Installer Tool Details

6-18

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |