|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 10-3930-623-34

1-16. The distributor times the occurrence of the ignition

1-19. The flow divider (priority) valve directs the pump

spark in relation to the engine by means of a set of

output to both the power steering system and the control

breaker points operated by an engine-driven cam.

valve assembly inlet port. A relief valve in the flow

Variations in timing under changing speed are

divider valve limits hydraulic pressure in the power

accomplished through a centrifugally operated spark

steering system. This relief valve cracks open at 700 psi

advance mechanism in the distributor. The timed high

and is fully open at 1050 psi.

voltage impulses are fed through the center terminal of

the distributor cap to the rotor inside. The rotor then

1-20. The control valve assembly is a two-spool fluid

directs the high voltage to each spark plug wire

control valve with a control handle for each spool. The

(arranged from cap to spark plugs in proper engine firing

inboard control handle and spool control the raising and

order) in sequence, to spark each spark plug at the

lowering of the forks by applying or releasing hydraulic

proper time.

pressure to the hoist cylinder. The outboard control

handle and spool control tilting of the upright carriage.

1-17. HYDRAULIC PUMP. Hydraulic pressure for

Each control handle has two actuating positions with a

steering, hoisting, and tilting of the uprights is supplied

center neutral position. A pilot operated relief valve

by an engine-driven hydraulic pump. This pump is

limits system pressure to 1500 psi. The hoist cylinder is

mounted at the left rear side of the engine, driven by a

a two-stage single-acting unit, raised by applying fluid

gear which engages the camshaft timing gear. The

pressure, and lowered by releasing pressure to permit

pump is a gear type positive displacement pump.

gravity return of the elevated parts. The tilt cylinders are

double-acting cylinders.

1-18. UPRIGHT CARRIAGE AND FORK ASSEMBLY

Using

1-21. POWER STEERING GEAR. The power steering

HYDRAULIC SYSTEM (See figure 1-4).

pressure from the engine-driven hydraulic pump, this

gear unit is basically a Saginaw recirculating ball

system controls raising of the forks and fore and aft

steering gear to which has been added a torque

tilting of the uprights. The control valve assembly

sensitive valving arrangement, and in which the ball nut

permits the operator to direct pressure to the hoist

has been redesigned to act as a hydraulic piston. The

cylinder for raising the forks, or to the tilt cylinders to

valve (see figure 1-6) is an open-center rotary three-way

adjust the angle of the uprights and forks.

valve, with a grooved spool to

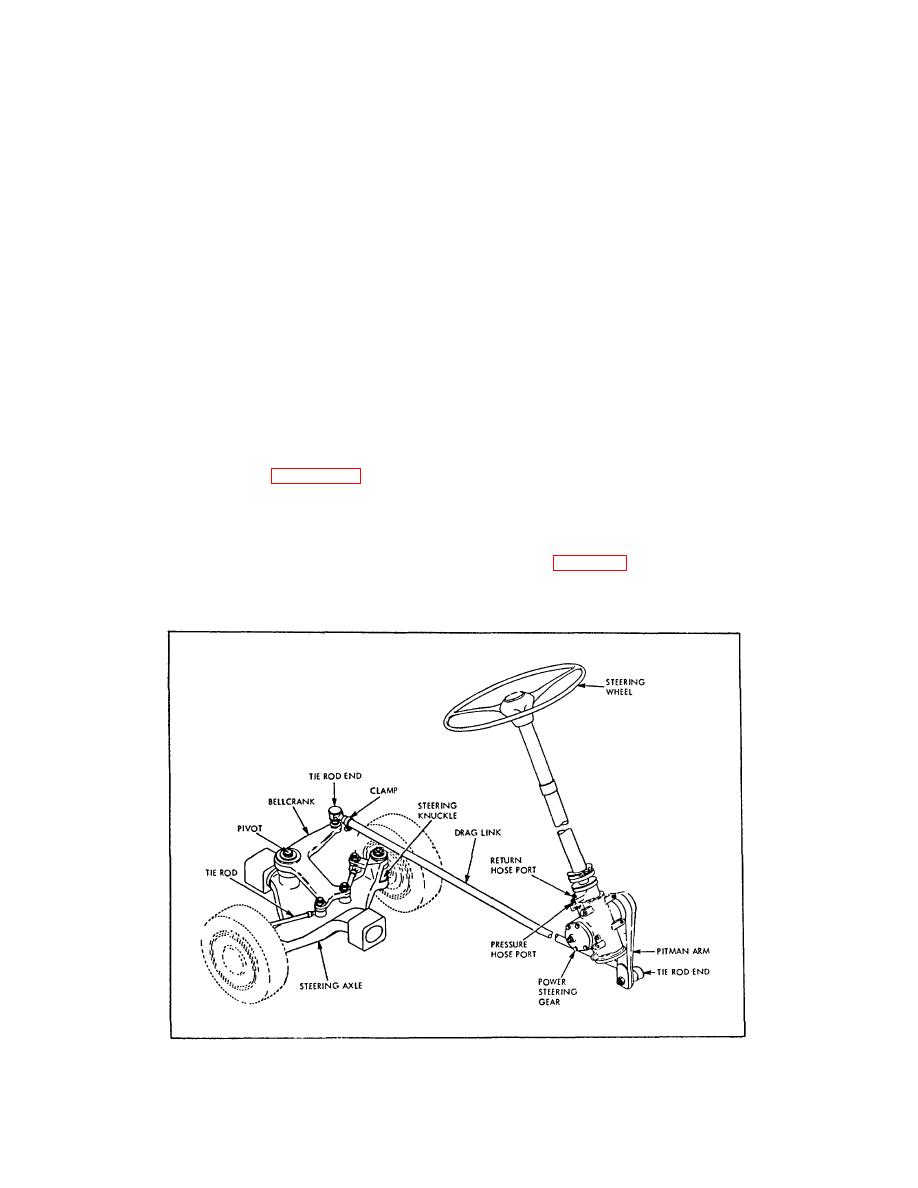

Figure 1-5. Steering System Arrangement

1-5

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |