|

|||

|

|

|||

|

Page Title:

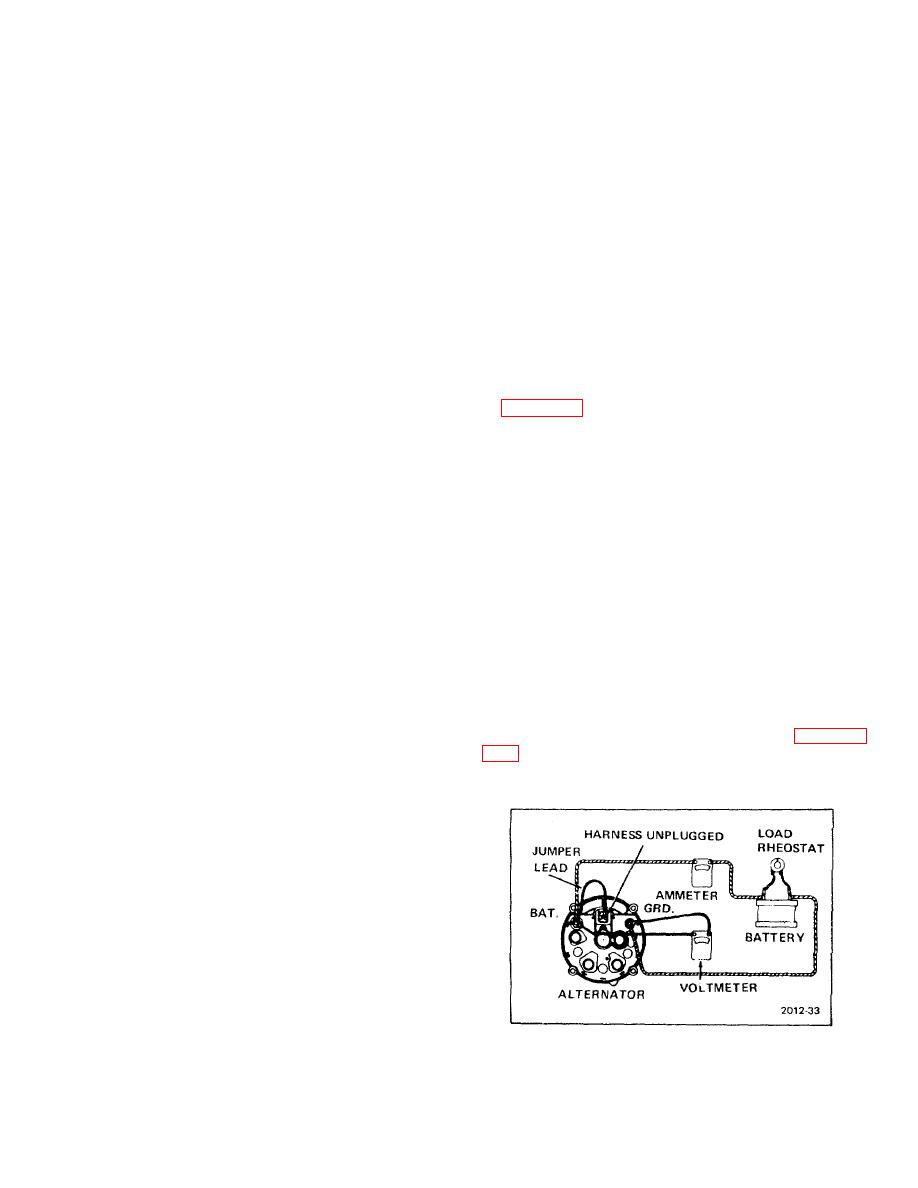

Figure 5-12. Alternator Test Setup |

|

||

| ||||||||||

|

|

TM 10-3930-623-12

b. Inspect alternator for cracked housing, bent

shaft, or damaged drive pulley. Turn shaft by hand; it

should rotate freely with no catching or binding. Replace

or repair damaged alternator.

c. Alternator Test.

(1) Connect assembled alternator as shown

in figure 5-12. Make sure negative terminal is connected

to ground. Adjust load rheostat to obtain specified

output of 14 volts. Check amperage at 2000 alternator

rpm or 1000 engine rpm (cold); it should be 21 amperes.

Check amperage at 5000 alternator rpm or 2500 engine

rpm (cold); it should be 30 amperes. Operate alternator

until it is at operating temperature.

Check output

amperage; it should be 32 amperes.

(2) If output is not as specified, replace

d. Alternator Installation.

(1) Position alternator on mounting bracket;

secure with mounting bolt.

(2) Loosely attach alternator to adjusting strap

with cap screw. Move alternator down and slip belts

over pulley. Adjust belt tension as directed in paragraph

Connect alternator as

Figure 5-12. Alternator Test Setup

5-11

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |