|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 10-3930-623-12

3. If timing mark does not appear centered in hole,

5. Tighten distributor clamp bolt, reinstall spark plug

loosen distributor clamp bolt just enough to permit

and plug wire.

rotation by hand of the entire distributor with a slight

drag.

While observing timing mark with light, turn

5-31. DISTRIBUTOR MAINTENANCE.

distributor in its mounting hole until timing mark is

centered in hole.

1. Contact Point Cleaning. Dirty contact points should

be dressed with a few strokes of a clean, fine-cut contact

4.

Retighten distributor clamp bolt, and recheck

file. The file should not be used for other metals and

timing.

should not be allowed to become greasy or dirty. Never

use emery cloth to clean contact points.

Contact

5-30.

STATIC TIMING METHOD.

The following

surfaces, after considerable use, may not appear bright

instructions presume the timing needs only minor

and smooth, but this is not necessarily an indication that

adjustment. If the distributor has been removed from the

they are not functioning satisfactorily. Do not attempt to

engine, refer to the instructions for reinstallation of the

remove all roughness nor dress the point surfaces down

distributor in Section 6; otherwise, proceed as follows:

smooth; merely remove scale or dirt. Badly burned or

pitted contact points should be replaced and the cause

1. Remove spark plug from number 1 cylinder. With

of trouble determined so it can be eliminated. High

ignition switch OFF, seal plug hole with thumb, and

resistance or loose connections in the condenser circuit,

crank engine (or turn it slowly by turning the fan by hand)

oil or foreign materials on the contact surfaces, improper

until pressure can be felt at plug hole. This pressure

point adjustment or high voltages may cause oxidized

indicates piston is coming up on compression stroke.

contact points. Check for these conditions where burned

contacts are experienced. An out-of-balance condition

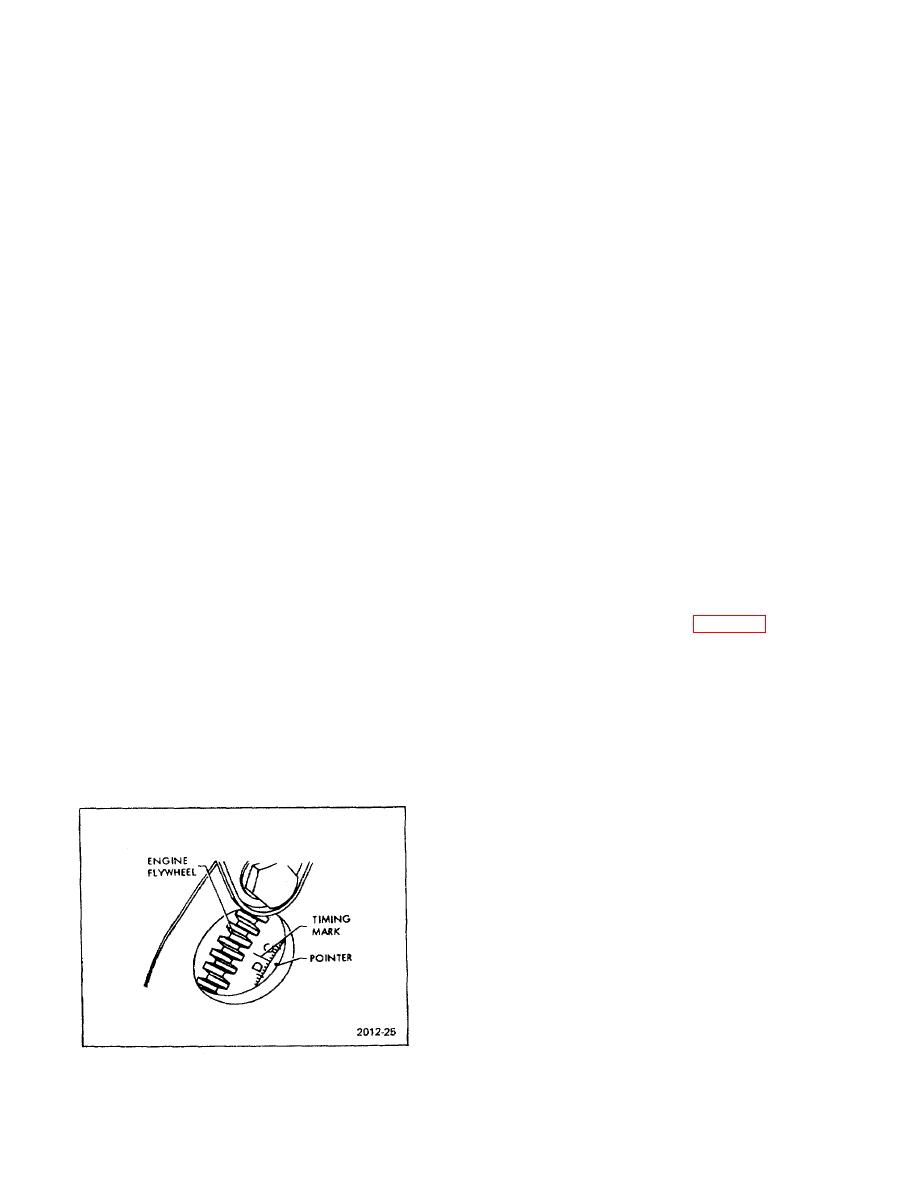

2. Continue to turn engine slowly until timing mark is

in the ignition system, often the result of too much or too

seen through hole in flywheel housing as shown in figure

little condenser capacity, is indicated where point pitting

54. Center mark in hole.

is encountered.

3. Remove distributor cap, loosen distributor clamp

2. Contact Point Replacement.

bolt, and turn distributor counterclockwise until breaker

points are definitely closed.

a. Release distributor cap hold-down

screws,

remove cap and place it out of work area.

4. Turn ignition switch ON. Turn distributor body

clockwise slowly until exact position is reached at which

b. Remove rotor.

breaker points separate. Do not over travel beyond this

point. Reaching this position will be indicated by one or

c. Disconnect primary and condenser lead wires

more of the following:

from contact point terminal (see figure 5-5).

a. A slight spark can be seen at the points if

d. Remove contact set attaching screw, lift cont act

distributor cap is removed.

point set from breaker plate.

b. The ammeter reading (discharge) will decrease

e. Clean breaker plate of oil smudge and dirt.

suddenly.

f. Place new contact point assembly in position on

c. With distributor cap installed and spark plug end

breaker plate, install attaching screw.

of number one plug wire held about 1/8 inch from

cylinder head, a spark will be seen.

CAUTION

Carefully wipe protective film from

point set prior to installation.

NOTE

Pilot on contact set must engage

matching hole in breaker plate.

g. Connect primary and condenser lead wires to

terminal on contact point set.

h. Check and adjust points for proper alignment

and breaker arm spring tension. Use an aligning tool to

bend stationary contact support if points need alignment.

Figure 5-4. Flywheel Timing Marks

5-5

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |