|

|||

|

|

|||

|

Page Title:

BLEEDING SERVICE BRAKE SYSTEM |

|

||

| ||||||||||

|

|

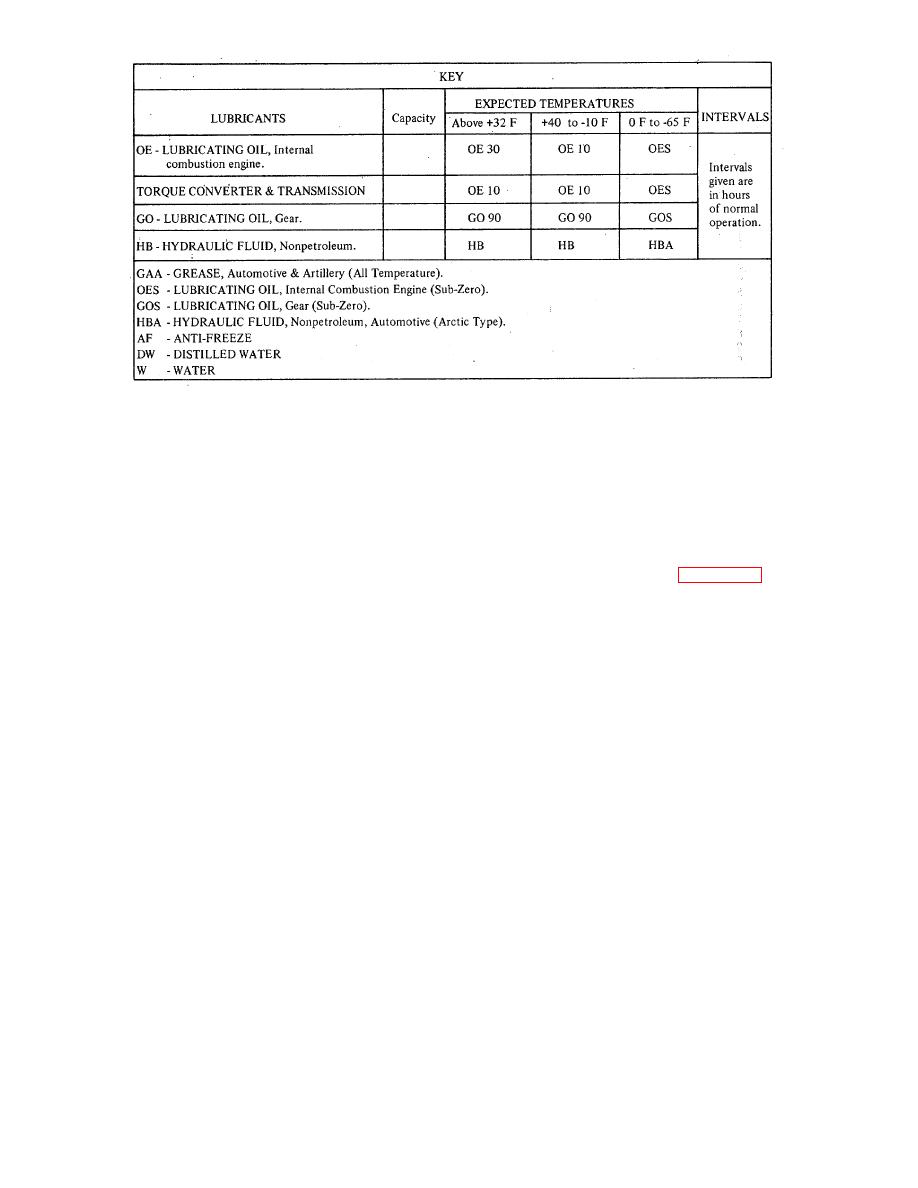

Figure 5-13. Lubrication Chart (Sheet 3 of 3)

from the foundation brake for service, turn these cams

each wheel cylinder is bled. Replace filler plug in master

as necessary to back off the adjustment. The drums can

cylinder.

then easily be removed.

CAUTION

5-77. BLEEDING SERVICE BRAKE SYSTEM. The

Hydraulic brake fluid bled from the

hydraulic brake system must be bled to expel air that

brake system must not be reused.

enters when the lines have been broken or

disconnected. The need is generally indicated by springy

5-78. LUBRICATION.

or spongy brake pedal action. Two men are required to

bleed the system. One to maintain a constant supply of

fluid in the master cylinder and to pump the brake

truck includes information pertaining to the type of

pedals. The other man is necessary to perform the

lubricant, lubricating time interval and location of

bleeding operation.

lubricating points. The service intervals specified in the

lubrication chart are for normal operation where

a. Remove filler plug from master cylinder and fill

moderate temperature, humidity and

atmospheric

with hydraulic brake fluid.

conditions prevail. Reduce the service intervals when

b. Clean the bleeder screws. Attach one end of

operating the truck under unusual conditions to

bleeder hose to bleeder screw and place other end of

compensate for abnormal or extreme conditions.

hose in clean container partially filled with hydraulic

brake fluid. Be sure end of hose is submerged in the

NOTE

hydraulic fluid.

For

breaking

in

a

new

or

c. Turn bleeder screw counter-clockwise three-

reconditioned engine, an SAE 30 non-

quarters of a turn. Apply a steady pressure to the brake

detergent oil is recommended for the

pedal. Hydraulic fluid containing air bubbles should be

first 40 hours of engine operation.

forced through the bleeder hose into container.

Vehicles are shipped from the factory

d. Maintain the fluid level in master cylinder and

with a break-in oil which should be

continue to operate brake pedal until the fluid flows in a

changed after 40 hours of operation.

steady solid stream without air bubbles. Close bleeder

screw by turning in clockwise direction. Remove bleeder

5-80. AIR CLEANER. The air cleaner on this vehicle

hose.

prolongs the life of the engine by preventing dirt and grit

e. Repeat the bleeding procedure at the other

from being drawn through carburetor and manifold into

wheel, replenishing brake fluid supply in master cylinder

the engine and causing excessive wear. The air cleaner

before

41

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |