|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

5-62. STARTING AND CHARGING SYSTEM.

5-63.

STARTING MOTOR INSPECTION AND

CLEANING.

Remove the commutator end cover.

Inspect the commutator for dirty condition, roughness,

high spots and high mica. If the commutator is dirty,

remove the brushes

and

carefully

clean

the

commutator with a commutator stone. Blow out dust

with compressed air and replace brushes in their original

brush holders. If the commutator is rough, out-of-round

or has high mica, replace the starting motor.

5-64.

STARTING MOTOR BRUSH INSPECTION.

Inspect brushes and replace if they are excessively worn

or oil soaked. Brush spring tension should be checked

with a spring scale. To check the tension of brush

spring, hook scale 'under the brush spring near the brush

and pull on a line parallel with the side of the brush.

Take the reading just as the spring leaves the brush.

Spring tension should be 35 ounces. If the spring

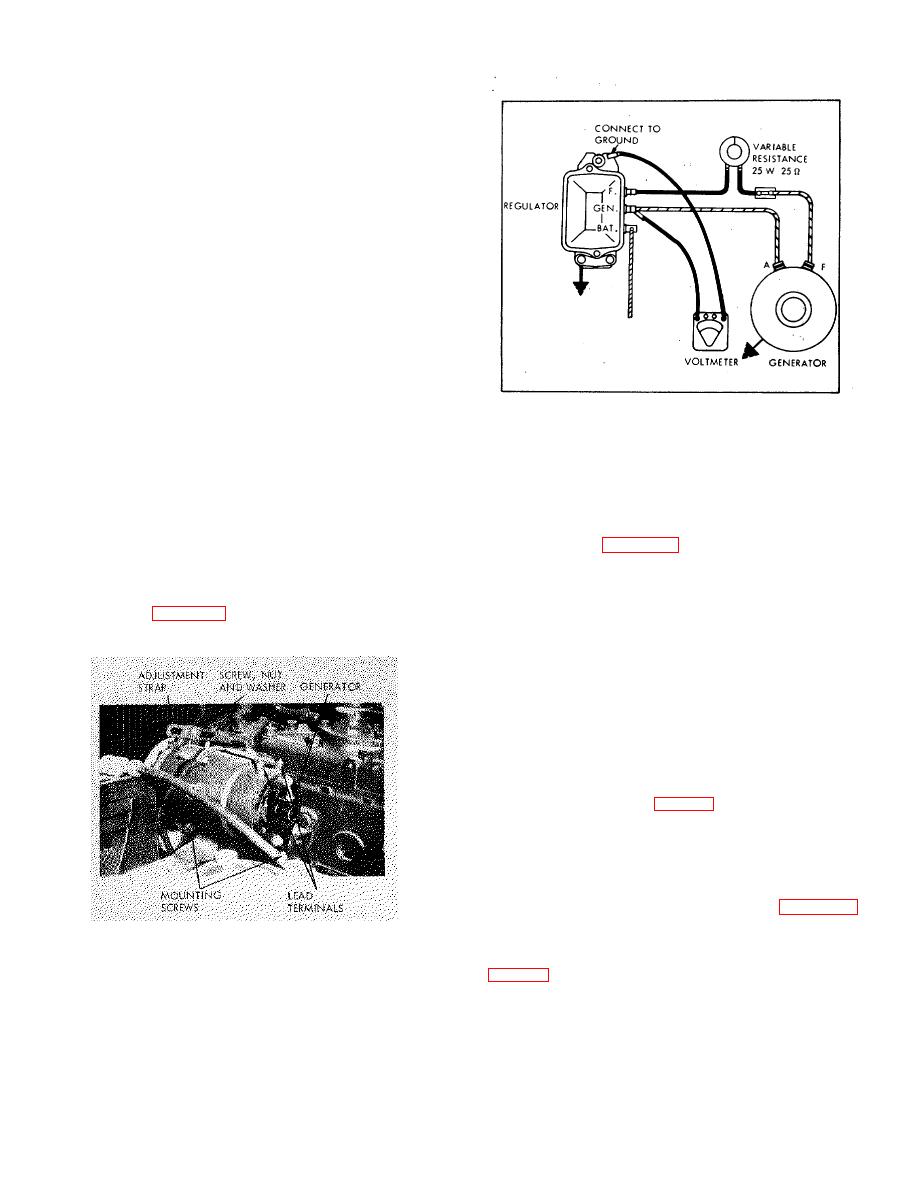

Figure 5-7. Cutout Relay Test Setup

tension is too low, there will be a loss of efficiency due to

poor brush contact.

If tension is too great, the

c. Remove mounting screws at underside of

commutator and brushes will wear excessively and have

generator. Disengage generator from fan belt and

short life. It is, therefore, important the brush spring

remove generator.

tension be kept within the limits specified. To adjust

spring tension, twist the spring at holder with a long-

5-66. GENERATOR INSTALLATION.

nosed pliers.

5-65. GENERATOR REMOVAL.

belt to 1/2-inch deflection under thumb pressure, midway

in long span.

a. Disconnect and tag leads at generator lead

b. Repolarize generator, after all electrical

terminals. (See figure 5-6).

connections have been made, by briefly shorting

b. Remove adjustment screw, nut and washer at

together the BAT and GEN terminals of the generator

strap.

regulator with a jumper wire, or a screwdriver blade, just

long enough to cause a spark.

5-67. GENERATOR REGULATOR TESTING.

a. Cutout Relay Test.

(1) Disconnect lead at regulator F terminal

and connect 0.25 ohm 25 watt variable resistor in series

with F terminal and lead (Fig. 5-7).

(2) Connect voltmeter from GEN terminal to

ground on frame. Remove regulator cover and operate

engine at fast idle.

(3) Increase field resistance until cutout relay

opens, then decrease it until points close. Observe

voltage at which points close (refer to Table 2-1).

Perform step b. below next.

Figure 5-6. Generator, Installed

b. Voltage Regulator Test.

(1) Disconnect battery lead from BAT terminal

more) watt resistor between the BAT terminal and

ground on frame.

35

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |