|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

Operate engine until temperature gauge stops rising and

CAUTION

remains stationary. Without changing engine speed, put

Do not hold air or water hose too

end of rubber tube in bottle of water. Be sure there are

close to radiator or use too great a

no kinks or sharp bends to restrict air flow. Watch for air

pressure as damage to the radiator

bubbles in the water as an indication that air is entering

may result. Clean out any stoppage

the cooling system. Correct the condition by tightening

in drain cocks with a soft wire.

cylinder head screw assemblies, water pump mounting

bolts, hose clamps and all fittings. Replace all hose that

5-54. FILL 'SYSTEM. Close radiator and cylinder block

is cracked, swollen or otherwise deteriorated.

drain cocks. Fill system to suit climate conditions as

b. Gas leakage test. Start test with a cold engine.

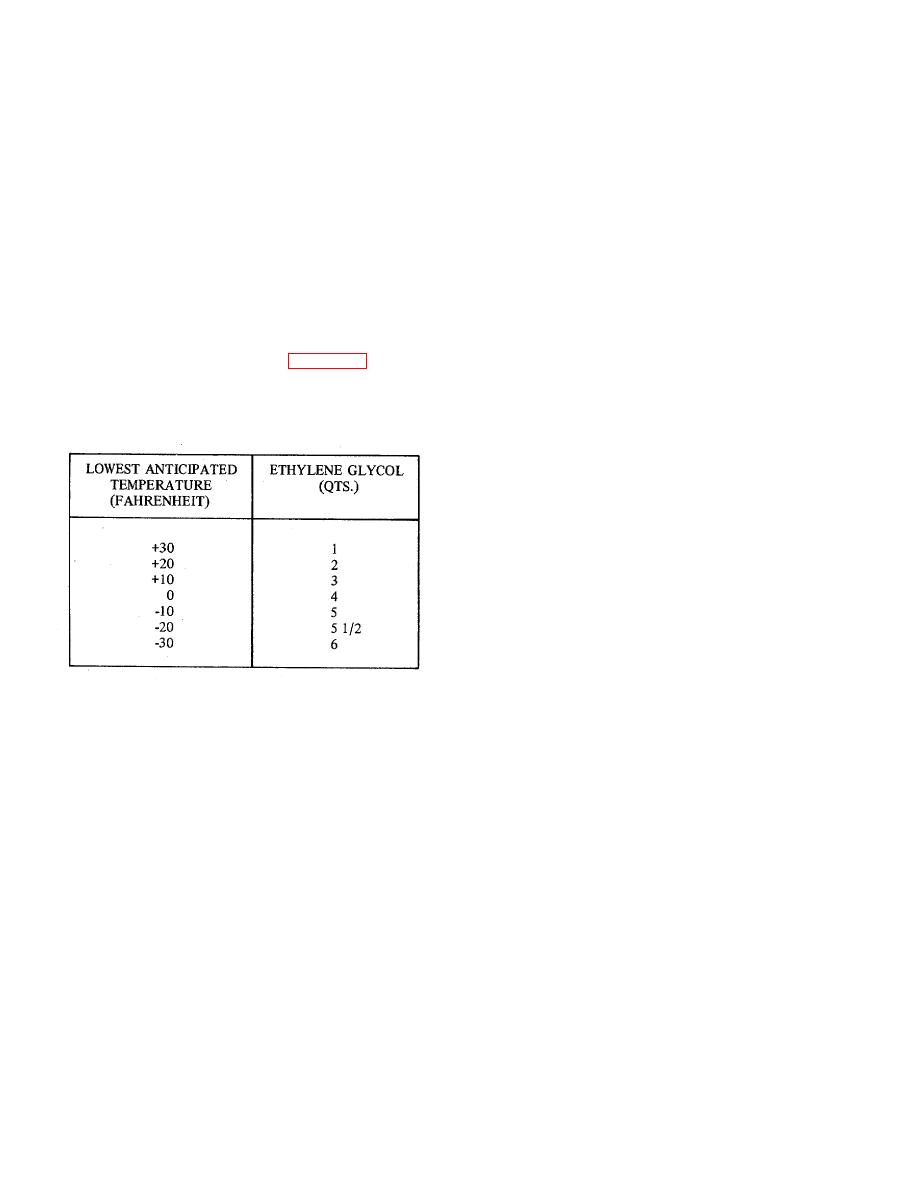

follows: If the prevailing temperature is above 32. deg

Remove thermostat and reinstall thermostat housing

Fahrenheit, partially fill the system with clean, fresh water

without thermostat or water outlet hose. Add water to

(soft, if possible). Add corrosion inhibitor compound and

level of housing outlet. Disconnect drive belt from fan

fill system with water until coolant is evident at radiator

and water pump pulley. Start engine, accelerate several

opening. If there is a possibility that temperatures below

times and watch for bubbles in thermostat housing. The

32 deg Fahrenheit will be encountered, pour about

appearance of bubbles or the sudden rise of liquid when

one gallon of water into the radiator and add anti-freeze

accelerating is evidence of exhaust gas leakage into

as required to safeguard cooling system freezing at

cooling system.

Make test quickly before coolant

lowest expected temperature (See Figure 5-3). Fill with

reaches boiling point as steam will give misleading

water to level of filler neck, install radiator cap, start

results. Correct the condition by replacing cylinder head

engine and operate at fast idle until temperature gauge

gasket and repeat test. If leakage is still evident, a

shows normal operating temperature. Stop engine and

cracked cylinder head, requiring a major engine

check coolant level. Add water, if necessary.

overhaul, is indicated. Install thermostat and connect

radiator hose. Fill radiator. Install and adjust fan and

alternator drive belt.

5-56. RUST PREVENTIVES. The cooling system must

be free of rust and scale to maintain efficiency of the

system.

The use of corrosion inhibitor compound

reduces or prevents corrosion of metals and prevents

formation of scale. Inhibitors are not cleaners and do not

remove rust or scale already formed. Treating the

cooling system with the inhibitor consists of adding the

compound to the coolant. The inhibitor should be

renewed periodically, especially if the system has been

cleaned or flushed.

5-57. FAN BELT ADJUSTMENT. Loosen the two cap

screws attaching generator to the mounting bracket.

Figure 5-3. Anti-freeze Requirements

Loosen the cap screw attaching generator to the

adjusting arm and move generator either away from or

5-55. LEAKAGE TESTS. Air in the cooling system or

toward the engine as necessary to obtain correct belt

exhaust gas leaking into the system, causes rapid

tension. A light pressure applied to the belt mid-way

corrosion and rust formations which will eventually clog

between the generator and water pump must produce a

the system and cause overheating and loss of coolant.

one-inch belt deflection. When properly adjusted tighten

Air may be drawn into the system due to low liquid level

the cap screw attaching generator to the adjusting arm

in the radiator, leaky water pump or loose fittings.

and then tighten the two cap screws between generator

Exhaust may be blown into the cooling system, past the

and mounting bracket.

cylinder head gasket or through cracks in the cylinder

head and crankcase.

5-58. IGNITION SYSTEM.

a. Air suction test.

Bring level of coolant to

maximum capacity in radiator. Drain out one and one-

5-59. IGNITION TIMING. Ignition timing requires

half pints of coolant to prevent overflow during test. Be

adjustment of the distributor assembly so that high

sure radiator cap is in good condition and will make an

voltage impulses are delivered to the spark plugs in

air-tight seal. Attach a length of rubber tubing to the end

proper time relation to piston position. Efficient operation

of the overflow tube, being certain the connection is air-

of the engine requires that a spark be produced in the

tight.

combustion chamber when the piston is in top dead

center on the compression stroke. Timing is checked by

means of a timing hole through the bellhousing for

33

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |