|

|||

|

|

|||

|

Page Title:

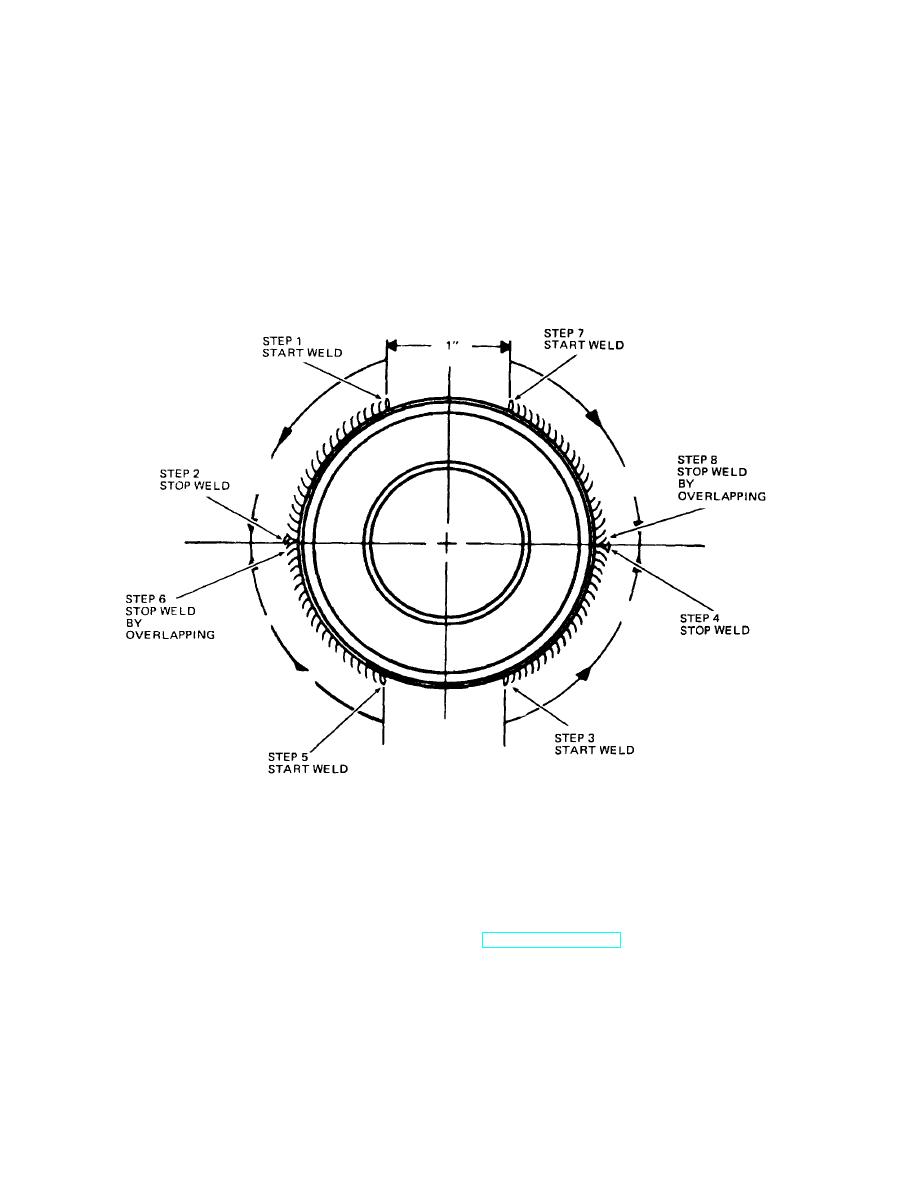

Figure 10-5. Bearing stud welding procedure |

|

||

| ||||||||||

|

|

TM 10-3930-621-34

3/

(5) Comply with the following welding specifications

Plate Thickness Range ............ 8" - 1"

using bearing stud welding procedure (fig. 10-5):

Electrode:

Type ...................................... Stick

Process ............................ Shielded Metal Arc

Class ..................................... E 7018 (hydrogen free)

3/

Size ....................................... 8"

Equipment ........................ Manual

Flux ....................................... Electrode Covering

Settings:

Weld Type and Size ................. 1/4" Fillet

Current.............................. A.C.

Number of Passes ................... 1

Amps ........................... 275 / 325

Position .................................... Horizontal

Volts............................. 31/33

Preheat..................................... 400F

Base Metal........................ (1) AC 1035-D

Interpass .................................. 250F

.................................................. (2) AC 41L40-HT (roller

stud)

Postheat ................................... None

Figure 10-5. Bearing stud welding procedure

(6)

When welding is completed

g. Replace defective parts as authorized.

remove all slag, weld spatter, and excessive weld

h. If studs (3, fig. 10-3) or outer mast bearings (6)

material.

are replaced, attaching screws (38) must also be

(7)

Finished

weld

must

be

replaced.

magnafluxed for defects.

10-14. Assembly

(8)

Remove defective material with

a pencil grinder in 0.010-0.020 of an inch passes and

Note. Prior to assembly, lubricate all parts per

visually

inspect

for defects

after each

pass.

TM 103930-621-12.

Magnaflux is to confirm disappearance of defect.

a. Refer to figure 10-3 and assemble as follows: b.

d. Inspect mast channels for misalinement, broken

Install lubrication fittings (66 and 67) and bearings (2) in

welds, excessive wear, worn or damaged wear strips.

outer mast (1).

e. Inspect pivot and tilt cylinder brackets on outer

c. Assemble intermediate mast (7) as follows:

mast for wear or damage. Check pivot bearing.

(1) Install bearings (6) and same size and

quantity of shims (4 and 5) on welded intermediate mast

f. Repair by welding if practical, provided heat

bearing studs (8), if bearings and shims were removed

distortion is avoided.

during disassembly.

10-10

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |