|

|||

|

|

|||

|

Page Title:

Chapter 2. GENERAL MAINTENANCE INSTRUCTIONS |

|

||

| ||||||||||

|

|

TM 10-3930-621-34

CHAPTER 2

GENERAL MAINTENANCE INSTRUCTIONS

Section I. REPAIR PARTS, SPECIAL TOOLS, AND EQUIPEMENT

Support maintenance on , he Model MHE-209 Fork Lift

2-1. Special Tools and Equipment

Truck.

There are no special tools and equipment required to

Section II. TROUBLESHOOTING

perform Direct Support and General Support

2-4. General

Maintenance on the Model MHE-209 Fork Lift Truck.

This section provides information useful in diagnosing

2-2. Direct Support and General Support

and correcting unsatisfactory operation or failure of the

Repair Parts

MHE-209 Fork Lift Truck and its components.

Direct and General Support maintenance repair parts are

Malfunctions which may occur are listed in table 2-1.

listed in TM 10-3930-621-35P.

Each malfunction stated is followed by a list of probable

causes of the trouble. The corrective action

2-3. Specially Designed (Fabricated) Tools

recommended is described opposite the probable cause.

and Equipment.

There are no specially designed tools and equipment

required to perform Direct and General

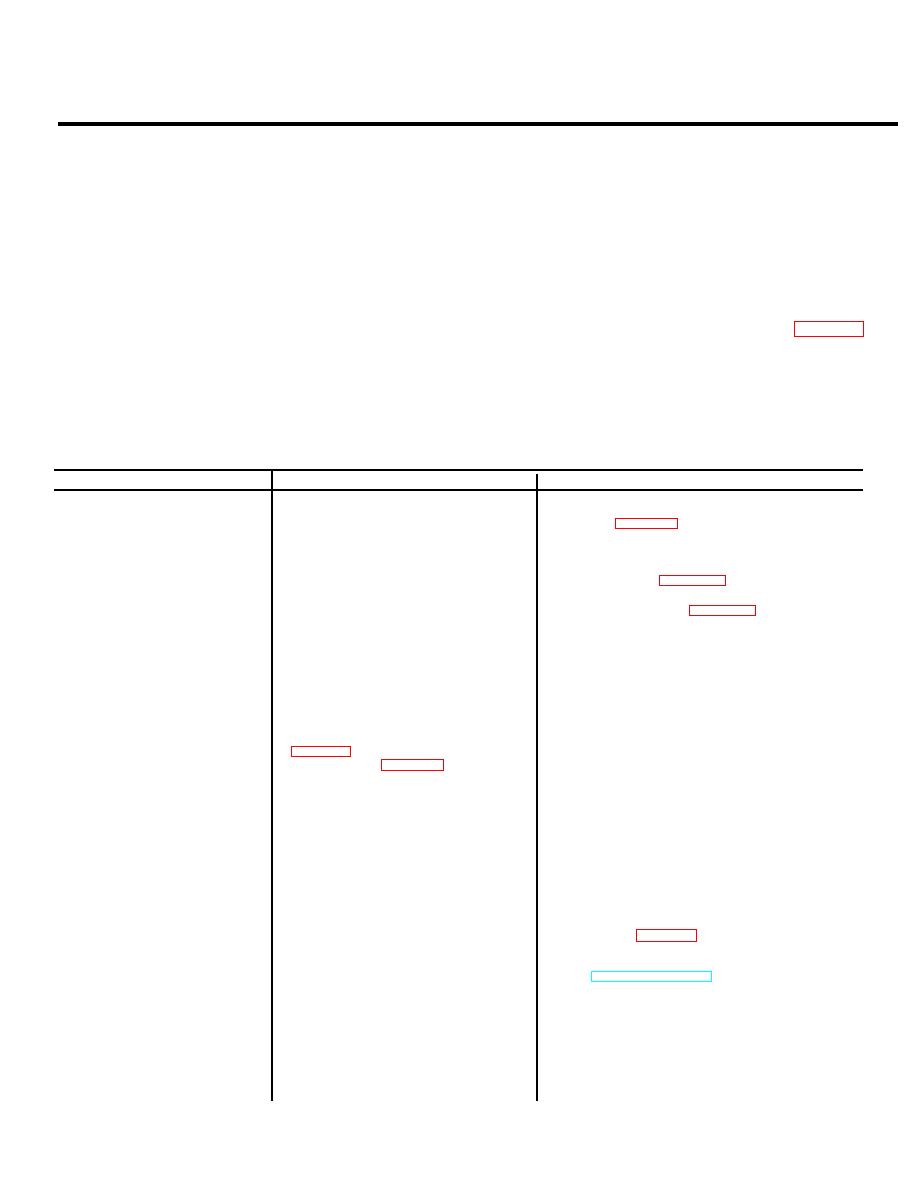

Table 2-1. Troubleshooting

Malfunction

Probable cause

Corrective action

a. Warped valves.

a. Replace (para 3-17).

1. Engine misses

b. Stuck valve

b. Clean stem and guide. Grind valve if

necessary.

a.

Loose connecting rod bearings (sharp a. Replace bearings (para 3-31).

2. Engine knocks.

knock, low oil pressure).

b.

Loose main bearings (heavy knock ,

b. Replace main bearings (para 3-31).

low oil pressure).

c.

Loose piston pins sharp double

c. Replace pins, or bushings (para 3-

knock).

26).

d.

d. Replace pistons and rings (para 3-

Piston and cylinder wear.

26).

a.

a. Remove oil relief valve, clean and

3. Loss of power.

Sticking oil relief valve.

replace. Do not stretch spring.

b. Leaky valves

b. Adjust or grind valve as necessary

c. Worn piston rings.

c. Replace rings (para 3-26).

a. Partially open exhaust valve.

a. Clean, adjust, or replace broken or

4. Explosion in exhaust

defective spring.

a. Warped exhaust valve.

a. Replace valve.

5. Engine runs irregularly.

b. Leaky valves.

b. Adjust, grind, or replace as

necessary.

a. Transmission control valve linkage

a. Adjust control valve linkage (para 6-

6. Transmission does not shift, or, truck

will not move.

out of adjustment.

23).

b. Transmission control valve dirty or

b. Clean, repair or replace dirty or

defective.

defective valve (para 6-13).

c. Dirty transmission fluid.

c. Check transmission fluid and replace

with fluid specified in Lubrication

Order. (TM 10-3930-621-12).

d. Transmission fluid low.

d. Fill with fluid as specified in LO 10-

3930-621-12.

2-1

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |