|

|||

|

|

|||

|

Page Title:

Cleaning, Inspection and Repair. |

|

||

| ||||||||||

|

|

(2) Install cylinder in mounting bracket and place

pin (6) and washers (10) through bracket and cylin-

der.

(3) Secure pin and cylinder in bracket with screw

(8) and lock washers (7).

(4) Remove plugs from hoses and cylinder and

connect hoses (5 and 11) to adapters (4) in cylinder.

e. Adjustment. Set the steering wheels straight

ahead and parallel with frame. Adjust tie rods (para

3-69) to obtain correct toe-in, if necessary. Adjust

steering cylinder as follows:

(1) If cylinder is installed, remove cotter pin (1,

yoke from ball on pivot arm.

(2) Pull cylinder rod one-half way out of cylinder.

Rod should extend approximately four inches.

(3) Hold cylinder rod with open end wrench on

flats provided. Turn yoke assembly in or out on rod

until yoke ball socket is centered over ball on pivot

arm.

(4) Install yoke on ball and tighten adjusting

plug (16) to hold yoke in position. Secure adjusting

plug with cotter pin (1).

(5) Tighten nut (3) to secure yoke assembly in

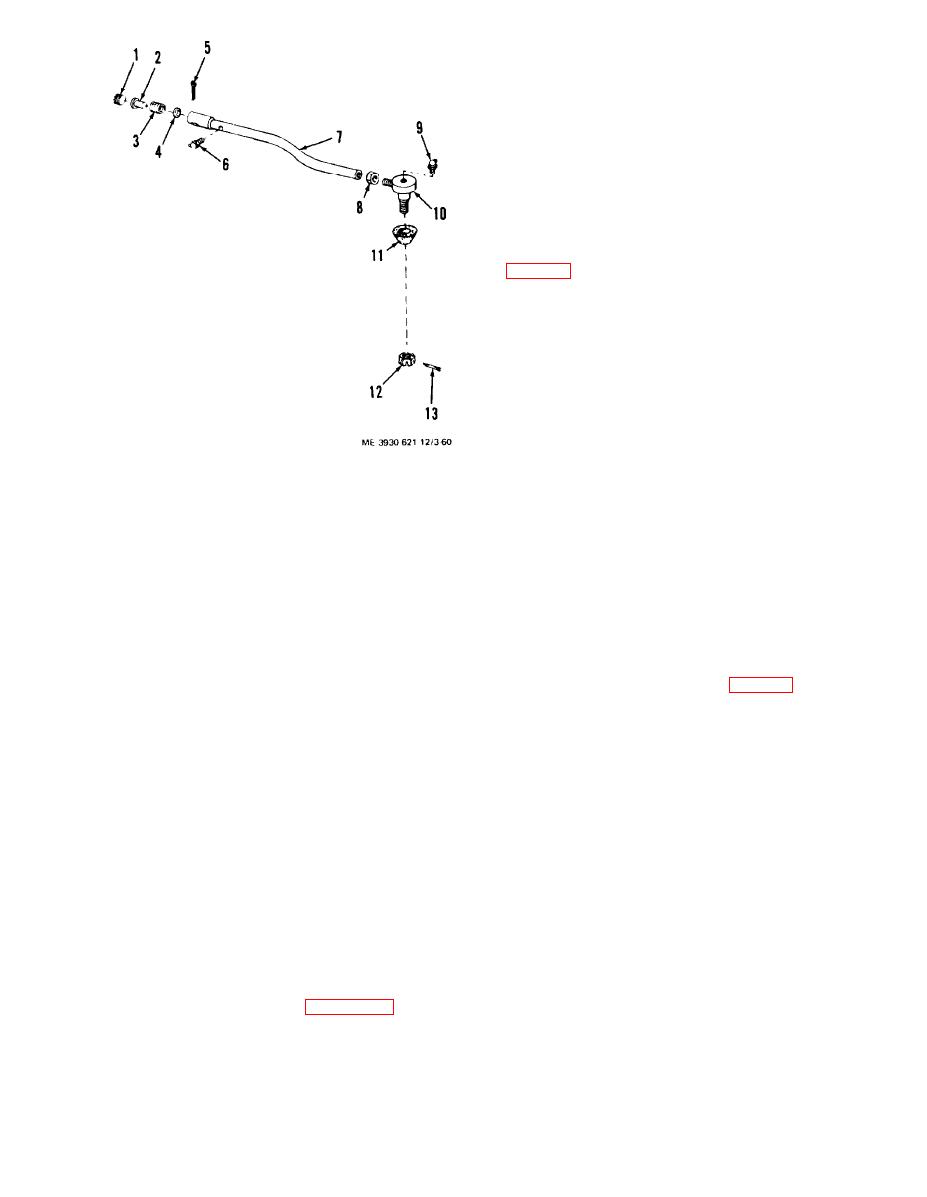

1. Adjustingplug

8. Nut

position on cylinder rod.

9. Lubrication

2. Ball seat

3. Spring

fitting

(6) Lubricate cylinder and yoke with grease

4. Spacing washer

10. Ball socket

(GAA).

5. Cotter pin

11. Boot

6. Lubrication

12. N u t

(7) Lower truck to floor and remove jacks or chain

fitting

13. Cotter pin

hoist.

7. Tie rod tube

(8) Check hydraulic oil level in reservoir and fill

Figure 3-60. Tie rod,

to FULL mark on dipstick.

exploded view.

(9) Start engine and operate steering wheel to

full right and full left. Wheel spindles should contact

stop screws on steering axle to prevent piston from

bottoming in cylinder. Loosen nut (fig. 3-62) and ex-

(4) Install screw in end of pin (6) and remove

tend stop screws, if necessary, to stop spindle travel

pin and flat washers (10) from cylinder and bracket.

before cylinder piston bottoms.

(5) Remove cotter pin (1) from end of yoke ball

socket (12) and loosen adjusting plug (16) far enough

to remove ball socket from ball on pivot arm.

(6) Remove cylinder and yoke from lift truck.

Loosen nut (3) on cylinder rod and remove yoke

from cylinder (17).

c. Cleaning, Inspection and Repair.

(1) Clean yoke parts with cleaning compound,

solvent (Spec. P-S-661) and dry thoroughly with

compressed air.

(2) Check all parts for dents and damage. Inspect

spring for damage.

(3) Inspect all threaded areas for stripping and

damage.

steering cylinder as follows:

(1) Install assembled yoke (12) and nut (3) on

cylinder rod.

3-53

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |