|

|||

|

|

|||

|

Page Title:

Service Brake Brake Shoes |

|

||

| ||||||||||

|

|

(2) Install master cylinder on frame and secure

with two screws and lock washers. Connect ground

wire with rear mounting screw.

(3) Connect clevis to brake pedal and secure with

clevis pin and cotter pin.

(4) Connect hydraulic brake line to master cylin-

der.

(5) Install stop light switch in fitting in master

cylinder and connect wires to switch.

(6) Refer to c below to fill master cylinder and

bleed brake hydraulic system.

c. Bleeding Brake Hydraulic System. Each time

the system has been drained or refilled or a part has

been disconnected or replaced, the system must be

bled as follows:

(1) Remove filler cap on master cylinder and fill

to proper level (3/8 to 1/2 inch from top).

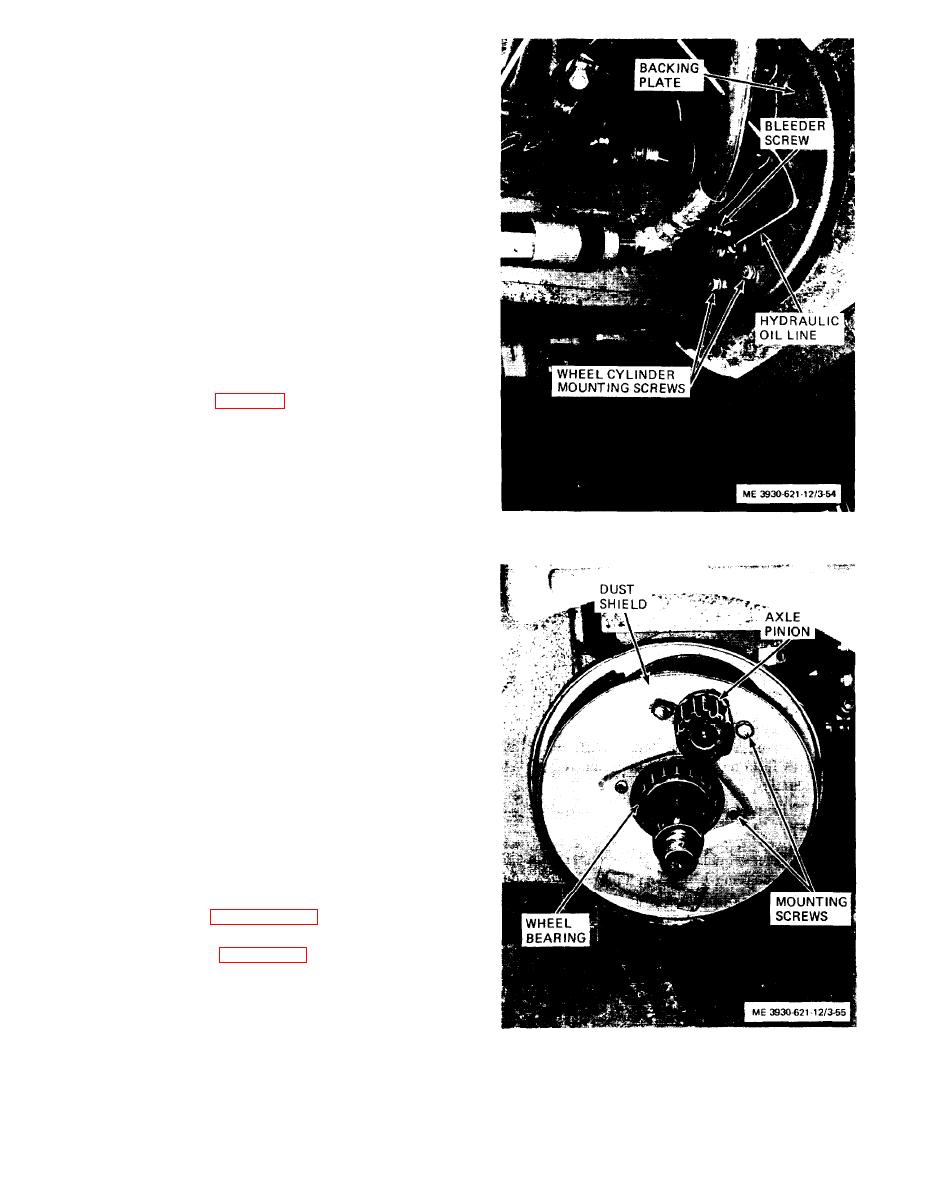

(2) Connect a bleeder hose to bleeder screw

on front wheel (fig. 3-54). Submerge other end of

hose in a glass jar filled with brake fluid.

(3) Open the bleeder screw one turn.

(4) Slowly depress brake pedal to end of travel

and release pedal. Observe hose in jar and repeat

pumping of brake pedal until no air bubbles escape

Figure 3-54. Service brake pedal

from the hose. Hold pedal at bottom of travel and

adjustment

close bleeder screw to keep additional air from

entering system.

Note. While pumping pedal, check fluid level in master cylin-

der. Add fluid to keep cylinder as close to full as possible at all

times during bleeding process.

(5) Repeat bleeding operation on remaining front

wheel bleeder screw.

(6) Fill master cylinder to proper level after

bleeding operation.

Caution: Discard fluid salvaged from brake sys-

tem during bleeding operation. Do not use in sys-

tem.

3-64. Service Brake Brake Shoes

a. General. The service brake brake shoes are

mounted beneath the dust shield. The shoes are

attached to the wheel cylinders and return springs.

b. Removal.

(1) Refer to paragraph 3-67 and remove the wheel

and tire assembly.

(2) Refer to figure 3-55 and remove the brake

dust shield as follows:

(a) Remove four screws and lock washers

securing dust shield to axle. Remove wheel bearing

from axle.

(b) Carefully remove dust shield from around

Figure 3-55. Service brake dust shield,

installed view.

axle pinion.

3-47

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |