|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

the combination rear lamp as follows:

(a) Install light on bracket and secure with

two nuts and washers. Connect wires to connectors.

(b) Install lamp. depressing lamp into socket

and turning lamp one-quarter turn clockwise.

(c) Install lens in light and secure by instal-

ling lock ring in groove in lamp.

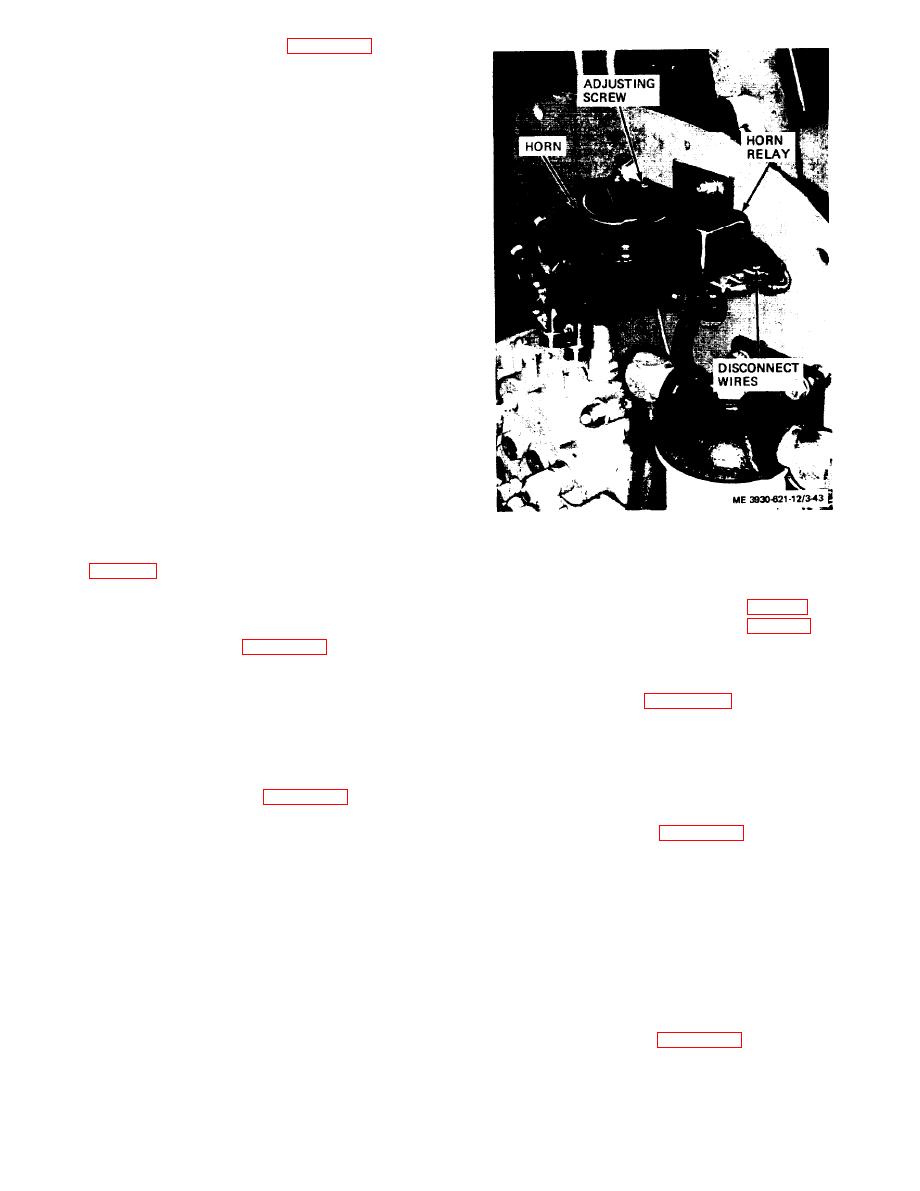

3-50. Horn and Horn Relay

a. General. The horn and horn relay are mounted

on the right post and are protected by the right hand

cowl.

b. Tests and Adjustments. In the event the horn is

not operating properly, check the battery voltage

before proceeding with the following tests.

(1) Remove three screws, one nut, and lock wash-

ers and remove right hand cowl.

(2) In event the horn is producing a weak signal

proceed as follows:

terminal and ground. Press the horn button and ob-

serve the voltage on voltmeter.

(b) If voltage is between zero and 10.7 volts,

check for an open circuit, defective horn relay, de-

fective wiring, or shorted horn coil.

(3) If voltage is normal and horn signal is weak,

Figure 3-43. Horn and horn relay, installed view.

increase volume by using volume adjusting screw

ing the engine unless the transmission is in neutral.

increase volume; counterclockwise to decrease.

Placing the transmission shift lever (fig. 2-2) into

(4) If defective horn relay is indicated, replace

neutral (N) position moves a cam lever (fig. 3-44) into

relay.

contact with the switch roller, closing the snitch and

completing the circuit. Check cam adjustment (d

and horn relay.

below) before replacing the switch.

(1) Tag and disconnect wires from horn and horn

relay.

switch as follow:

(2) Remove two nuts and washers from studs

(1) Disconnect wires leading from switch at con-

attaching horn to mounting bracket and remove horn.

nectors.

(3) Remove screw, nut, and lock washer securing

(2) Remove two screws, nuts, lock washers, and

horn relay to bracket and remove relay.

flat washers securing the switch to the support and

remove the switch.

horn and horn relay as follows:

(1) Install horn relay on bracket and secure with

switch as follows:

screw, nut, and lock washer.

(1) Install switch on steering column support and

(2) Install horn on bracket and secure with two

secure with two screws, nuts, lock washers, and flat

nuts and washers on horn studs.

washers.

(3) Connect wires to horn and horn relay.

(2) Connect wires from switch to connectors in

(4) Install right hand cowl and secure with three

wires from harness.

screws, nuts, and four lock washers.

(3) Operate shift lever and check switch opera-

3-51. Transmission Neutral Switch

tion. Cam on lever must contact switch roller and

open switch when shift lever is in forward or reverse

a. General. A normally opened switch, connected

positions. Adjust (d below) if necessary.

in series with the starter button and starter solenoid

switch, is attached to the underside of the steering

lever as follows:

column support bracket. The switch prevents start-

3-39

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |