|

|||

|

|

|||

|

Page Title:

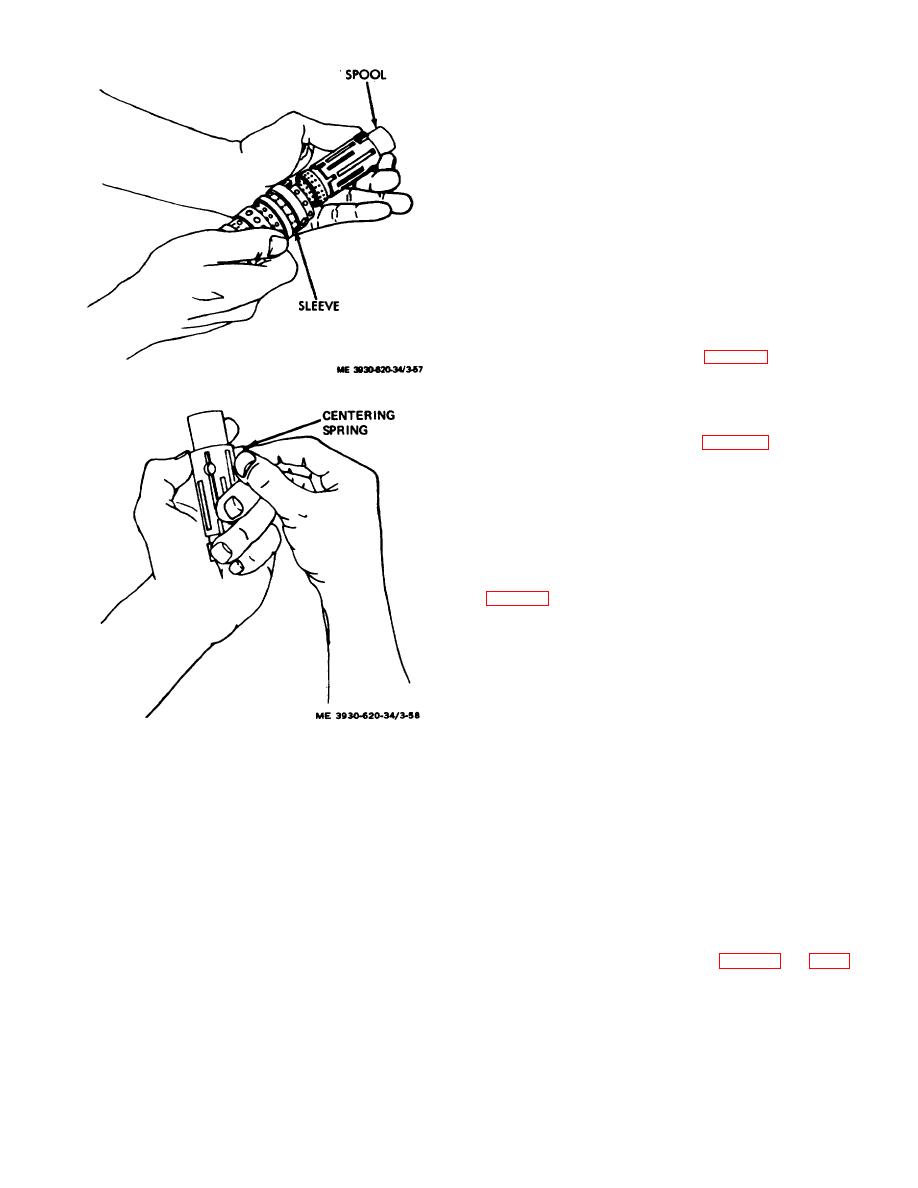

Figure 3-57. Spool removed from sleeve. |

|

||

| ||||||||||

|

|

(d)

Inspect each part to insure that surfaces

are completely polished.

Warning: Use

an

approved

cleaning solvent.

Wear suitable

eye

protection

when

using

compressed air.

(e) Clean each part in an approved solvent

and dry using compressed air.

(f) each cleaned part in an area free of

contaminants and other foreign matter.

d. Reassembly

(1) Secure power steer gear housing in a

suitable vise with control end facing upward and 14-hole

end resting on a clean wooden block.

(2) Clamp vise jaws lightly across the port

face.

(3) Install check valve spring into check hole

with large end facing downward. (fig. 3-59.)

(4) Install check ball into check hole and

Figure 3-57. Spool removed from sleeve.

insure it rests on top of small end of spring.

(5) Place check valve seat on hex wrench and

install it in check valve hole so that machined

counterbore seats on check ball. (fig. 3-60.)

(6) Torque check valve seat to 150 inch-

pounds.

Note.

Check ball does not

have to be snugged against seat to

function properly.

(7) Test check ball action by pushing ball

against the spring force using a small clean pin.

(8) Carefully install spool within the sleeve.

(9) Insure that spring slots of both parts are

located at the same end.

(10) Carefully rotate spool while sliding parts

together.

Caution: Insure

that

spool

rotates smoothly in sleeve when

fingertip pressure is applied at

splined end.

Figure 3-58. Spring being removed from spool.

(11) Check spool for freedom of rotation.

(12) With spring slots of both parts aligned,

(b) Remove sharp grit from abrasive paper

position parts on end and insert spring installation tool

by cleaning ends of star gear.

through slots in both parts.

(c) both sides of ring gear, both sides

(13) Position 3 pairs of centering springs (or 2

of plate, the 14-hole end of housing, and flat surface

sets of three each) on work bench so that extended edge

of end cap by rubbing against abrasive paper.

is facing downward and arched center section is

(6) Polish surfaces of meter section as follows:

together.

Note.

When hand polishing,

(14) While holding this position, insert one end

hold parts firmly against abrasive

of entire spring set into spring installation tool.

surface.

(15) Compress extended end of centering

(a) Stroke each surface across abrasive

spring set and push it into spool and sleeve assembly

paper several times.

while withdrawing installation tool. (fig. 3-62 and 3-63.)

(b) Check for bright areas on the surface

(16) Insure that spring set is centered in the

which may indicate the presence of a burr.

parts so they can be pushed down evenly and flush with

(c) Remove burr' by stroking surface across

the upper surface of the spool and sleeve assembly.

abrasive paper six to ten times.

(17) Install centering pin through spool

assembly and push into place until centering pin is

3-75

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |