|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

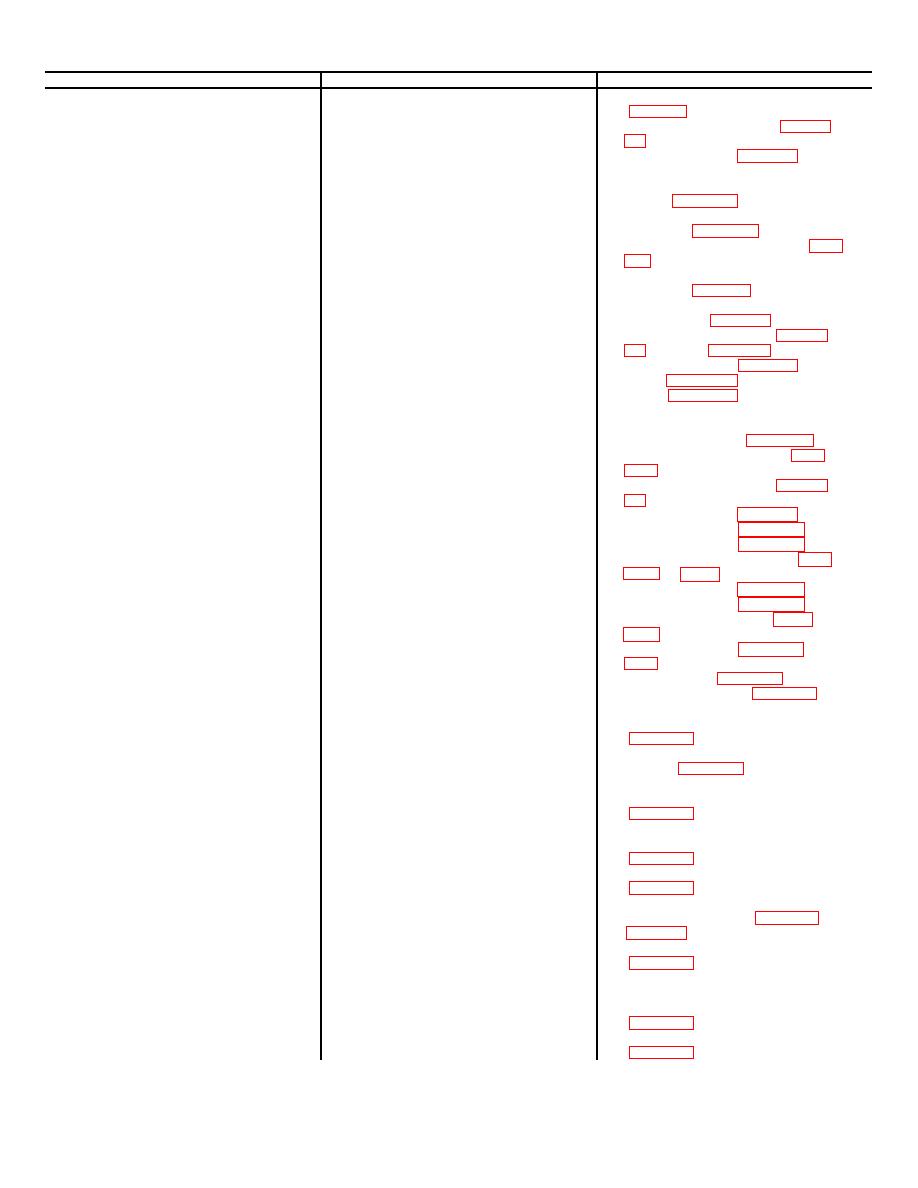

Table 2-1. Troubleshooting

Malfunction

Probable Cause

Corrective Action

1.

Directional contactors do not

a. Improperly positioned speed in-

a. Adjust speed interlock switch

pull in when accelerator pedal

terlock.

is pressed.

b. Directional switch open.

b. Inspect and repair switch )para 3-

c. Open in contactor, control relay, or

c. Inspect and repair (para 3-5).

direction interlock.

d. Protective circuit defective.

d. Test and replace circuit if nec-

essary (para 3-11).

2.

Directional contactors pull in

a. Defective capacitor and dio de

a. Test and replace assembly if

when accelerator pedal is press

assembly or resistor assembly.

necessary (para 3-10).

ed but lift truck does not move.

b. Control unit defective.

b. Test and replace if necessary (para

c. Bower switch assembly defective.

c. Test and repair or replace as

necessary (para 3-9).

3.

Inadequate power for climbing

One or more defective sections in

Test and repair or replace assembly

grades or moving loads

power switch assembly

as necessary (para 3-9).

4.

Hydraulic system inoperative

a. Overheated motor

a. Inspect and repair pump (para 3-

b. Pump contactor open

b. Inspect and repair (para 3-5).

5.

Brake pedal goes to floor.

a. Leaking master brake cylinder

a. Repair (para 3-32).

b. Leaking wheel cylinder

b. Repair (para 3-31).

6.

Harsh braking action or truck

Brake backing plate loose

Inspect and tighten if necessary (TM

pulls to one side

10-393()-620-12).

7.

Brake releases slowly

Dirt in master brake cylinder

Disassemble and clean (para 3-27).

8.

Steering difficult-

a. Defective power steering cylinder

a. Inspect and repair cylinder (para

b. Defective power steering pump.

b. Inspect and repair pump (para 3-

c.

Bower steering contactor open

c. Inspect and repair (para 3-5).

d.

Power steering motor defective

d. Inspect and repair (para 3-40).

9.

Fork carriage will not lift load.

a.

Hydraulic pump defective

a. Inspect and repair (para 3-24).

b.

Lift cylinders defective

b. Inspect and repair cylinders (para

c. Hydraulic pump motor defective

c. Inspect and repair (para 3-25).

d. Control valve defective

d. Inspect and repair (para 3-22).

10. Load creeps down from raised

a. Defective control valve

a. Inspect and repair valve (para

position.

b. Defective lift cylinder.

b. Inspect and repair (para 3-19 and

11. Lifting speed erratic

Bent or distorted mast assembly

Inspect and repair (para 3-27).

12. Control valve plungers will not

Defective control valve

Inspect and repair valve (para 3-22).

return to neutral.

13. No operation of hydraulic system

a. Defective hydraulic pump.

a. Inspect and repair hydraulic pump

when first started up.

b. Defective relief valve in control

b. Inspect and repair control valve

valve or control valve

plunger (para 3-24).

stuck.

14. Slow operation of hydraulic

a. Defective hydraulic pump.

a. Inspect and repair hydraulic pump

system.

b. Pump rpm too low.

b. Check pump motor operation.

Overhaul pump motor if required

c. Improper operation of direction

c. Inspect and repair control valve

control valve due to defective

Parts or foreign matter.

d. Worn or scored lift cylinder

d. Overhaul lift cylinder (para 3-19

packings.

15. Noisy operation of hydraulic

a. Defective hydraulic pump.

a. Inspect and repair hydraulic pump

system.

b. Chattering relief valve in control

valve.

16. Oil heats up rapidly.

a. Defective control valve.

b. Inspect and repair control valve

b. Defective hydraulic pump.

a. Inspect and repair hydraulic pump

2-3

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |