|

|||

|

|

|||

|

Page Title:

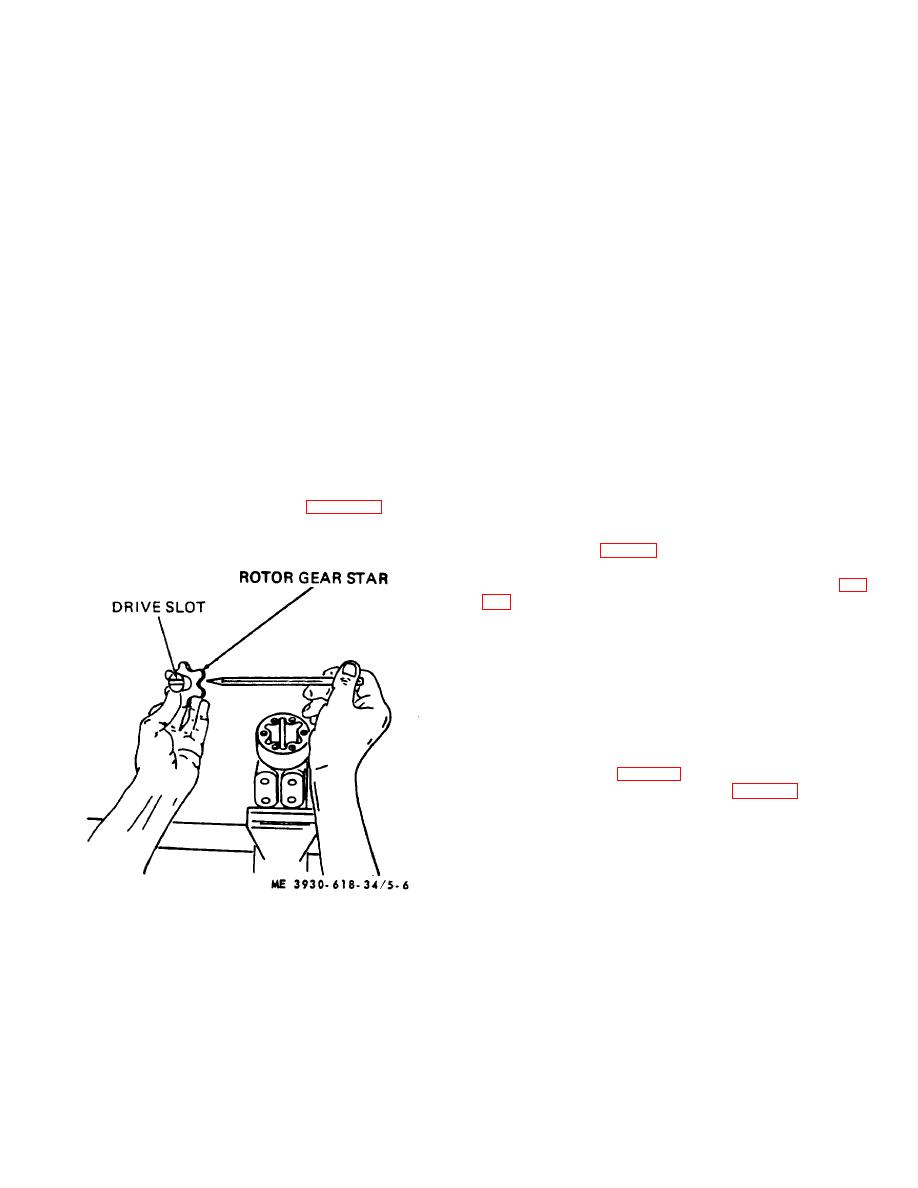

Figure 5-6. Drive-gear alinement. |

|

||

| ||||||||||

|

|

(6) Push splined end of drive (23) through the

NOTE

gear until spline extends about one-half its length beyond

Oil seal (16) lip must face away from unit

gear star. Hold it in this position while installing it in the

unit. Note position or direction of cross pin (41) within

(3) Place the mounting plate subassembly

the unit.

over the spool shaft and slide it down smoothly in place

(7) Install gear-drive assembly into rotor ring

over the cap locator bushing (39) so that seals will not be

(21), drive (23) first, and slowly rotate it to engage cross

damaged.

slot in drive (23) with cross pin (41). Splined end of drive

(4) Aline the bolt holes in the cover (17) with

will drop down against rotor ring (21) when slot engages.

the tapped holes in the housing 1481. Be sure the

CAUTION

mounting plate' rests fairly flush against end of housing

assembly so that the cap locator bushing is not cocked.

Alinement of the cross slot in the

(5) Install mounting plate attaching bolts (18)

drive with the valleys between the

and torque each to 150 inch-pounds.

teeth of the gear star determines the

i. End Plate.

proper valve timing of the unit. There

(1) Reposition control housing (48) in vise,

are 12 teeth on the spline and 6 on

clamping the mounting plate with 14-hole surface up.

the star. Alinement will be right in 6

(2) Check that control spool and sleeve are

positions and wrong in 6 positions.

flush or slightly below 14-hole surface and that surface is

Should the parts slip out of position

clean.

during this part of the assembly,

(3) Place end plate (22) over control spool

make certain that proper alinement is

and sleeve, alining bolt holes in plate with tapped holes

obtained.

in housing 1481.

(8) Place end cap (20) over assembly and

(4) Place rotor ring (21) on assembly and

install screws (19) finger tight, to maintain alinement of

aline bolt holes.

parts.

(5) Place splined end of drive (23) in rotor

(9) Secure assembly in vise and torque

gear star so slot at control end of drive is alined with

screws to 150 inch-pounds.

outside diameter valleys of gear. See figure 5-6.

j. Installation.

(1) Install steering gear and secure steering

gear support (22, fig. 5-2) in place on truck bracket with

flat washers (23), lockwashers (24), and screws (25).

(2) Install clip on upper part of column (36, fig.

(3) Connect brush assembly connector (13).

(4) Note identification marks on hydraulic

hoses and attach hoses to proper ports in control

housing (48).

(5) Install floor and toe plates (TM 10-

3930618-20).

5-6. Shifting Mechanism

a. Removal.

(1) Remove floor plate (TM 10-3920-618-20)

and steering wheel (para 5-3).

(2) Remove roll pin (4, fig. 5-7) holding

indicator (3) in position and move indicator up shaft.

(3) Remove capscrews (1) holding cover (5)

in place and move out of way.

(4)

Remove capscrews from steering

column support (19) and the two mounting brackets (8

and 27).

Figure 5-6. Drive-gear alinement.

5-8

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |