|

|||

|

|

|||

|

Page Title:

Table 3-2. Clutch Oil Pressures (Free Running) |

|

||

| ||||||||||

|

|

NOTE

the normal pressures at various rpm's.

The pressures are to be obtained with

oil at 200 F. and at indicated engine

speeds. (All pressures in pounds per

square inch ).

Table 3-2. Clutch Oil Pressures (Free Running)

Engine

Main Line

Converter

Forward

Reverse

RPM

Pump press

in.

clutch

clutch

minimum

maximum

minimum

maximu

minimum

maximum

minimum maximum

m

500

18

30

15

25

1

2

15

27

1000

..

..

..

..

..

..

..

..

1500

..

..

..

..

..

..

..

..

2000

90

115

65

80

70

87

70

87

(5) Cooler circuit. To check cooler circuit,

(g) Replace the drain plugs and fill

circuit must be open and relief valve setting must be

transmission with OE-10.

c. Removal.

within the proper range of 65- to 100-psi.

(a) The cooler hoses must not be

(1) Remove floor plates, seat deck (para 2-9),

crimped, crushed, bent, or deteriorated in any way which

front grille and seat support, battery case and battery and

might restrict the flow of oil.

one corner post (TM 10-3930-618-20).

(b) The cooler in the bottom of the

(2) Drain oil from transmission by removing

drain plug at rear of sump.

radiator must not be restricted in the flow of oil nor

(3) Disconnect cooler lines at the right and left

should the passages in the radiator be coated with lime

sides of the transmission housing.

deposits which will restrict transfer of heat from

(4) Remove all

control

linkage

from

transmission oil to cooling system.

(c) Disconnect the cooler return hose at the

transmission (para 2-9).

(5) Remove drive shaft from universal joints

return port on the left side of the converter housing

adapter. Plug the cooler return port. Install a 200psi

(6) Attach sling and hoist to transmission case

pressure gauge in the cooler hose. With the clutch

engaged and the oil pump temperature at 120 to 170F.,

holding converter housing to flywheel housing.

run the engine at governed speed. The relief valve

which protects the cooling oil circuit is preset and opens

at 65-psi to 100-psi. It should open near 100-psi, and

never under 65-psi. If pressure is below 65-psi or above

100-psi replace spring and copper washer.

(6) Overheating. When a transmission has

overheated and become sludged, the following

procedure for cleaning is recommended:

(a) Drain two quarts of oil from the

transmission.

(b) Add two quarts of OE-10 oil and

operate unit for 50 hours before drain and flush.

(c) At 50 hours, drain the transmission

oil while the transmission is warm.

(d) Fill transmission with OE-10 oil and

operate 10 minutes at high idle. DO NOT STALL.

Operate in both directions and drain.

(e) Clean oil screen with a small brush

or an air hose.

(f) Flush with one gallon of OE-10 oil. Make

certain all internal parts are thoroughly drained by

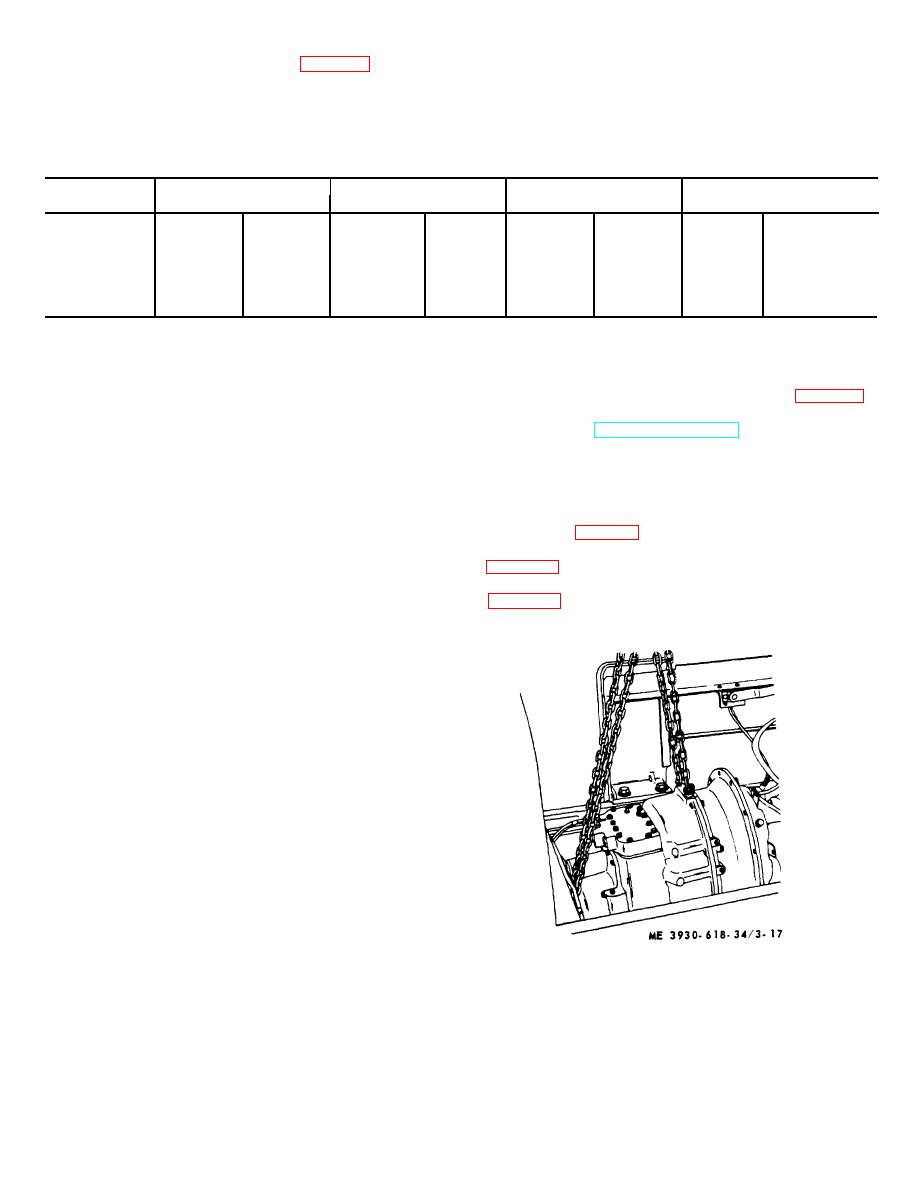

Figure 3-17. Transmission removal and installation.

removing the 1/8" pipe plug from the converter and

turning the engine by hand until the opening is straight

down. This will allow the fluid to drain from the converter

and out through the hole in the bottom of the flywheel

housing.

3-22

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |