|

|||

|

|

|||

|

Page Title:

Section VI. MAINTENANCE OF THE FUEL SYSTEM |

|

||

| ||||||||||

|

|

f. Advance the flywheel until the ignition timing

j. Start the engine and using the idle adjustment

line on the flywheel is aligned with the reference line

screw, lower the low idle speed to 400 RPM.

on the flywheel housing. This line is TDC (top dead

k. Direct the timing light at the timing hole in the

center).

flywheel housing and rotate the distributor to set the

g. If necessary, mark the flywheel and housing with

timing to TDC (0 ), then tighten the distribution ad-

white chalk or paint.

vance screw.

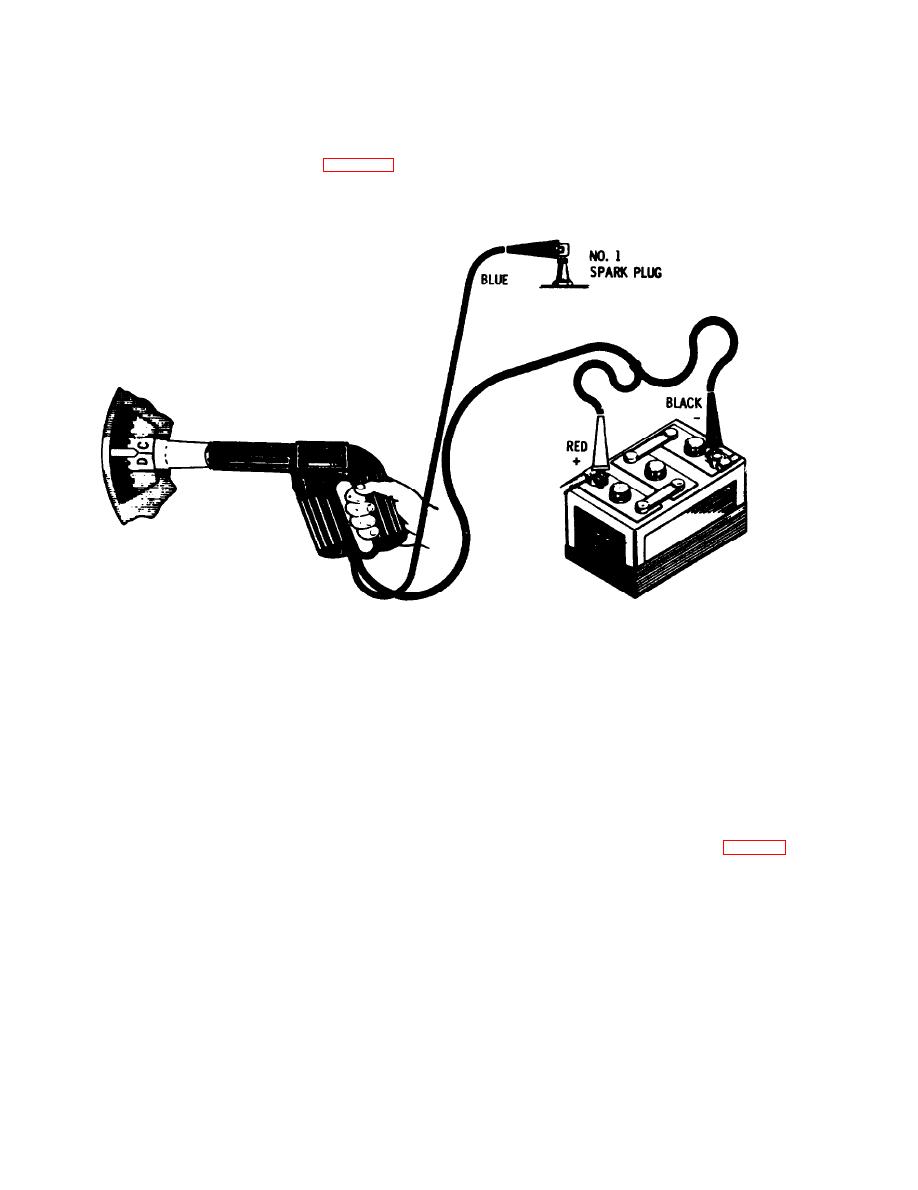

h. Connect a timing light as shown in figure 2-9.

I. Increase the low idle speed to 450 to 500 RPM.

i. Connect the hot lead of a tachometer to the

positive lead on the coil and connect remaining lead to

ground.

ME 3930-618-20/2-9

Figure 2-9. Timing light connections.

m. With the timing light, again check flywheel

ment of the flywheel timing mark. If the spark advance

timing and note whether IGN TDC line on flywheel

is functioning properly IGN TDC mark on the fly-

has moved away from reference line on flywheel

wheel will move counterclockwise away from the

reference line on the flywheel housing. As the engine

housing.

decelerates the IGN TDC on the flywheel will line up

n. After timing is correctly adjusted, accelerate

with reference line on flywheel housings.

the engine rapidly a few times and observe the move-

Section VI. MAINTENANCE OF THE FUEL SYSTEM

a. Removal. Loosen the hose clamp, unscrew the

2-15. General

wingnut, and lift out the filter assembly (fig. 2-10).

The fuel system is comprised of an 14.5 gallon capac-

b. Disassembly. Remove the cover and lift out the

ity tank, diaphragm-type fuel pump, single-venturi

oil cup.

updraft carburetor, centrifugal governor, and con-

c. Cleaning.

necting lines. A bowl type fuel filter is included as an

(1) Pour out the old oil from the oil cup and

integral part of the fuel system.

scrape away accumulated dirt from the bottom of the

2-16. Carburetor Air Cleaner

oil cup.

(2) Clean the cover, oil cup, and base assembly

CAUTION

inside and outside with SD.

Never remove the air cleaner while the engine

(3) Refill the oil cup (rapacity 1/2 pt) with engine

is naming.

oil of grade and weight presently used in the engine.

Do not run the engine unless the air cleaner

d. Assembly. Reverse procedures in b above.

is in place.

2-16

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |